Indoor grouting testing device under simulation of complex stress effect and testing method thereof

A technology of complex stress and test device, applied in measurement devices, suspension and porous material analysis, scientific instruments, etc., can solve the problems of long test time, high cost, inconvenient use, etc., to solve the grouting interface problem, shorten the test laboratory. effect of time

Inactive Publication Date: 2013-04-03

HUNAN UNIV OF SCI & TECH

View PDF7 Cites 44 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] One of the objectives of the present invention is to provide a test device for real-time observation and monitoring of the grout diffusion radius, the permeability coefficient of the stone body after grouting, and related grouting parameters of the rock and soil mass under different

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

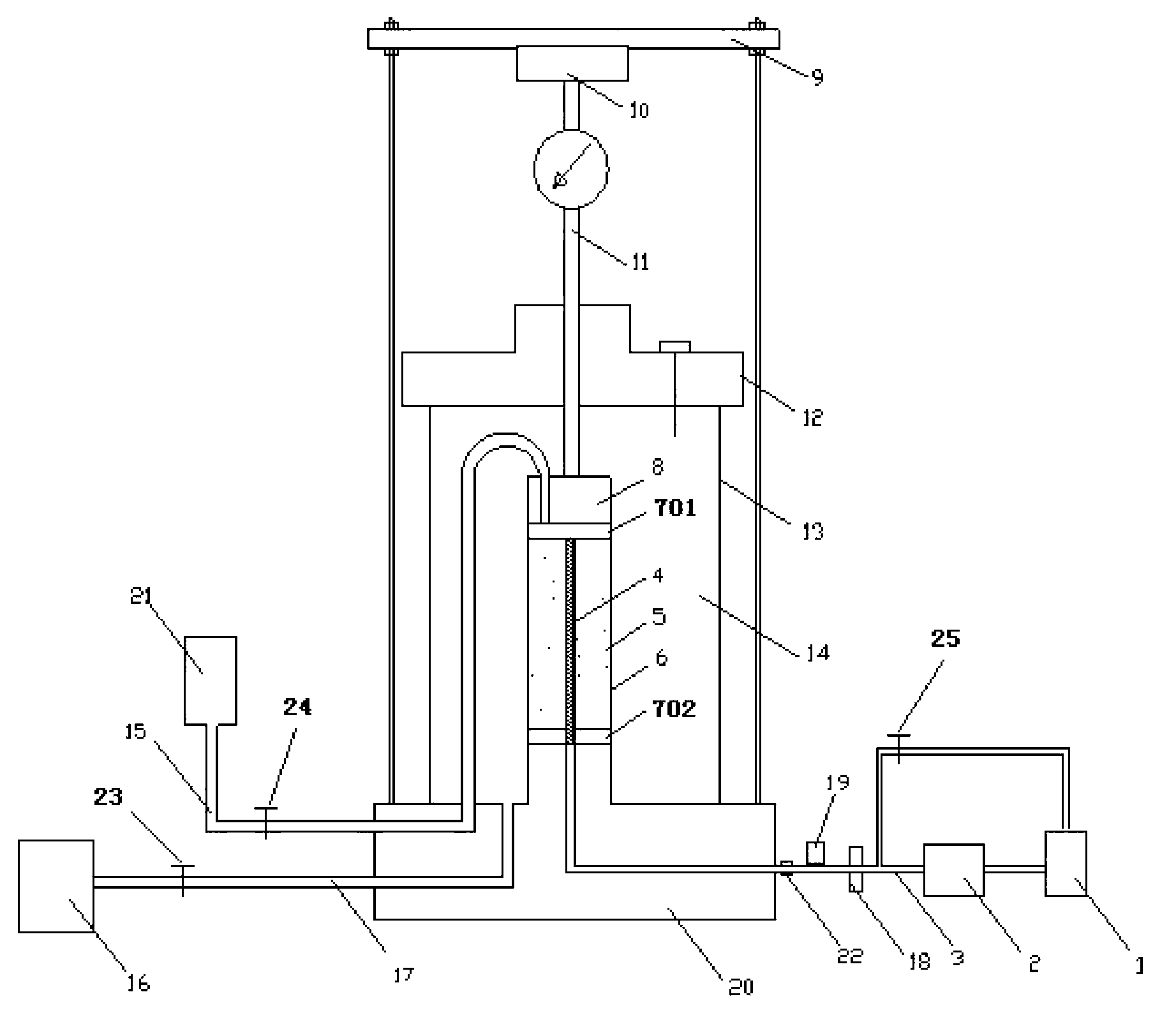

The invention discloses an indoor grouting testing device under simulation of a complex stress effect and a testing method thereof. According to the invention, a rock-soil sample is wrapped with a rubber membrane, and is provided with an upper permeable stone and a lower permeable stone on the upper surface and the lower surface thereof respectively; the upper permeable stone and the lower permeable stone are arranged in a closed surrounding pressure room; the upper permeable stone is provided with a pressurization plug; the pressurization plug is connected to an axial pressurization device through a force transfer rod; a surrounding pressure pipe is communicated with the surrounding pressure room, and the outer end of the surrounding pressure pipe is connected with a surrounding pressure system; a counter pressure pipe is connected with the upper permeable stone, and the outer end of the counter pressure pipe is connected with a counter pressure system; and a grouting filter pipe, placed in the axes of the rock-soil sample, is connected with equipment, such as a grouting pump, a slurry barrel and the like through grouting pipes. Through truly simulating the coupling effect between deep complex stress and underground water pressure, the slurry dispersion radius in rock-soil body grouting and the function relationship between the osmotic coefficient value of a grouted stone body and the related parameter are obtained. The device and the method shorten the time needed by tests, and achieve effects of convenience, reliability and accuracy.

Description

technical field [0001] The invention belongs to the field of deep geotechnical engineering, and specifically relates to a grouting test device and a test method for rock and soil bodies under different stress levels and different water pressures, and is mainly used to solve problems caused by complex stress and groundwater in the field of deep geotechnical engineering. Under the action of pressure coupling in rock-soil grouting engineering, the diffusion radius of grout and the permeability coefficient of stone body after grouting, and the functional relationship between the rock-soil medium structure, grouting pressure, grouting time, water-cement ratio, and grout viscosity Research. Background technique [0002] The diffusion radius of the grout and the permeability coefficient of the stone body after grouting are important indicators to reflect the grouting effect. They directly affect the arrangement of the grouting hole spacing and the anti-seepage reinforcement effect....

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N15/08

Inventor 陈伟贺建清戴习东朱建群王志斌崔大田

Owner HUNAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com