Device for measuring droplet contact angle and rolling angle under temperature control, humidity control and pressure control condition

A technology of contact angle and rolling angle, applied in the field of chemical measurement, can solve problems such as errors, image distortion results, limit the test range of contact angle and rolling angle, etc., and achieve high degree of automation, high test accuracy and good repeatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

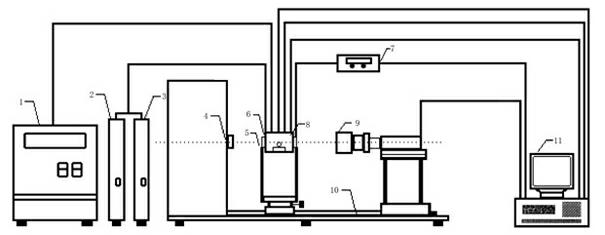

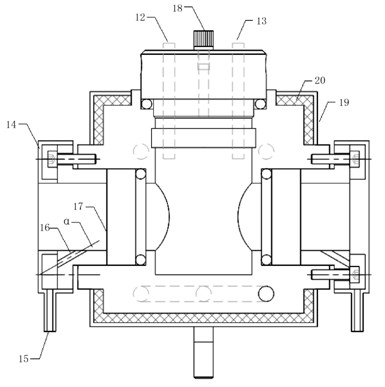

[0031] Example 1: The contact angle, rolling angle, advancing angle, receding angle and lagging angle of water droplets on a superhydrophobic surface under the conditions of 40°C, 60% relative humidity, and 0.5MPa pressure.

[0032] Fix the sample box on the rotating bracket. The rotating bracket is located between the light source and the high-speed camera lens. Place the sample to be tested in the center of the sample box. Adjust the position of the rotating bracket so that the LED cold light source, optical quartz glass , the high-speed camera (Phantom V12.0) are located on the same line, the LED cold light source illuminates the test drop through the optical quartz glass window, the high-speed camera system obtains the image data of the test drop through the optical quartz glass window, and the temperature The sensor, humidity sensor and pressure sensor are connected to the computer system, the stepper motor (Haydon Switch & Instrument INC.) is connected to the driver (Step...

example 2

[0034] Example 2: The contact angle and rolling angle of a water droplet on a glass surface at 0°C and a vacuum of 0.1kpa

[0035] Fix the sample box on the rotating bracket, the rotating bracket is located between the LED cold light source and the high-speed camera lens, place the sample to be tested in the center of the sample box, adjust the position of the rotating bracket so that the LED cold light source, optical quartz glass window, The sample surface and the high-speed camera are located on the same line. The LED cold light source illuminates the test droplet through the optical quartz glass window. It is connected to the computer system, the stepper motor is connected to the driver, the circulation pipeline in the sample box wall is connected to the temperature control system through the interface and the conduit, the vacuum pump is connected to the sample box, the anti-condensation exposed air port on the surface of the optical quartz glass is connected to the dry Th...

example 3

[0037] Example 3: At -10°C, 50% relative humidity, and normal pressure, high-speed tracking of the bouncing process of water droplets falling from a height of 0.5cm on a superhydrophobic surface with an inclination angle of 10°

[0038] Fix the sample box on the rotating bracket, the rotating bracket is located between the LED cold light source and the high-speed camera lens, place the sample to be tested in the center of the sample box, adjust the position of the rotating bracket so that the LED cold light source, optical quartz glass window, The sample surface and the high-speed camera are located on the same line. The LED cold light source illuminates the test drop through the optical quartz glass window. The high-speed camera system obtains the image data of the test drop through the window. The temperature sensor and humidity sensor installed on the sample box are connected to the computer system. Connection, the circulating pipeline in the wall of the sample box is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com