Plant blend oil and method for preparing same

A technology for blending oil and soybean oil, used in food science, edible oil/fat, application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

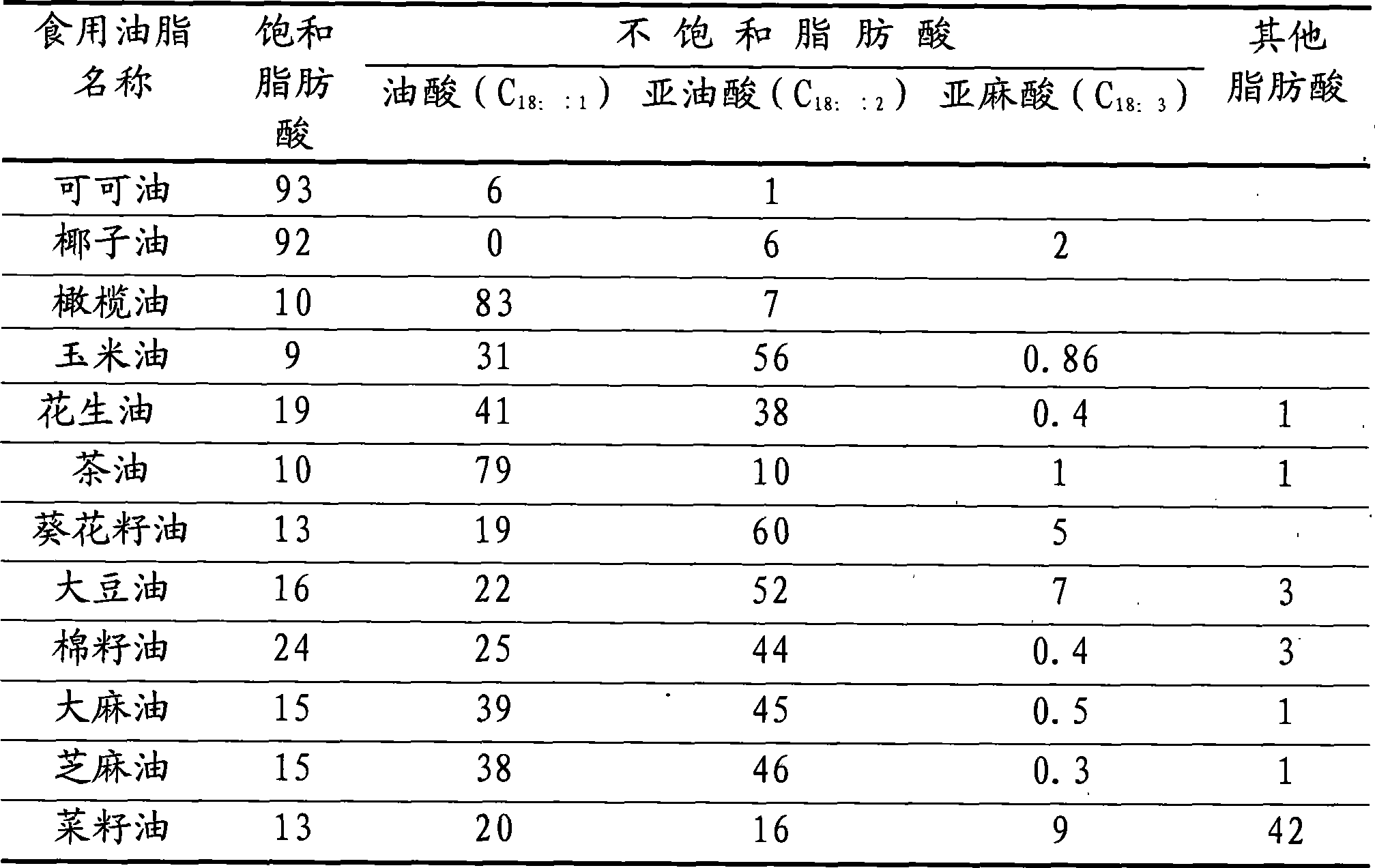

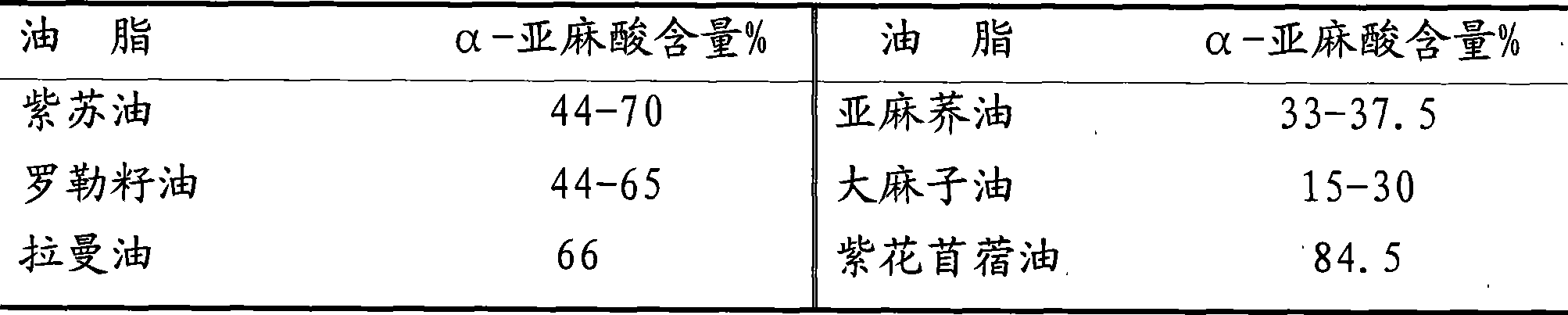

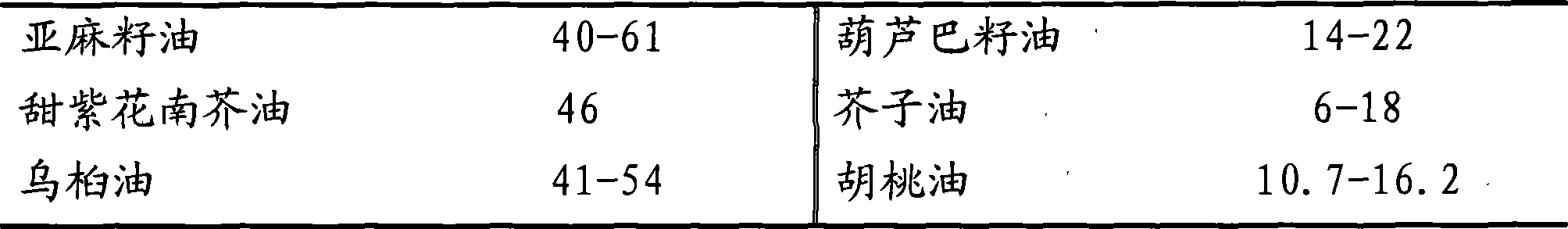

Method used

Image

Examples

Embodiment 1

[0028] 105 parts of corn oil, 15 parts of soybean oil, 13 parts of peanut oil, 9.5 parts of sunflower oil, 7.6 parts of rice bran oil, 3 parts of safflower oil, 4.5 parts of perilla oil, 8.9 parts of linseed oil, 8.5 parts of walnut oil, wheat Germ oil 7 parts, tea seed oil 10.4 parts, evening primrose oil 2.1 parts, vitamin E 0.025 parts.

[0029] Preparation method: add each component into the blending tank according to a certain weight ratio, start stirring after adding, make the speed reach 80-120r / min, fill the tank with an appropriate amount of nitrogen while stirring, and after 10-30 minutes Stop stirring, keep at room temperature for 24 hours, then fill to obtain the finished product.

[0030] In the following examples, the preparation method is the same as Example 1, so only the weight and number ratio of each component is listed in the following examples.

Embodiment 2

[0032] 12 parts of corn oil, 13.5 parts of soybean oil, 11 parts of peanut oil, 8.5 parts of sunflower oil, 8.5 parts of rice bran oil, 3.5 parts of safflower oil, 3.7 parts of perilla oil, 8.3 parts of linseed oil, 9.0 parts of walnut oil, wheat Germ oil 8 parts, tea seed oil 11 parts, evening primrose oil 3.0 parts, vitamin E 0.03 parts.

Embodiment 3

[0034] 12.5 parts of corn oil, 13 parts of soybean oil, 11.5 parts of peanut oil, 8.0 parts of sunflower oil, 8.0 parts of rice bran oil, 3.8 parts of safflower oil, 4.0 parts of perilla oil, 8.0 parts of linseed oil, 9.3 parts of walnut oil, wheat Germ oil 7.8 parts, tea seed oil 11.5 parts, evening primrose oil 2.6 parts, vitamin E 0.02 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com