Enzyme-method esterification deacidification technology for rice bran oil with high acid value

A high-acid value rice bran oil, enzymatic esterification technology, applied in fatty acid esterification, fat oil/fat refining, fat production, etc., can solve the problems of high reaction temperature, environmental pollution, low efficiency, etc., and achieve mild catalytic conditions , high catalytic efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

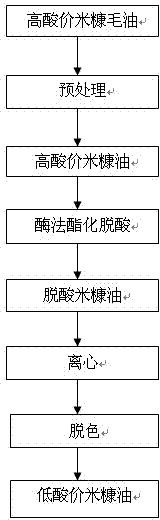

Method used

Image

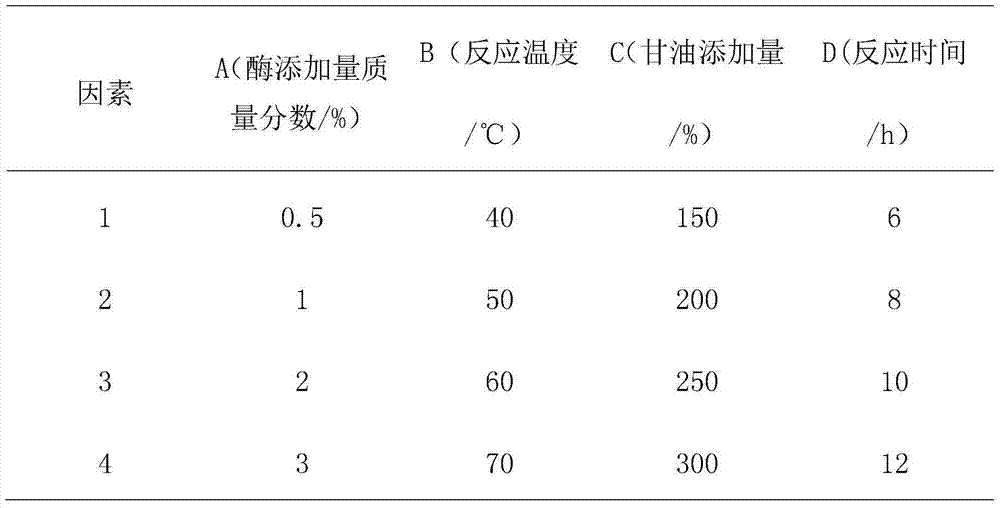

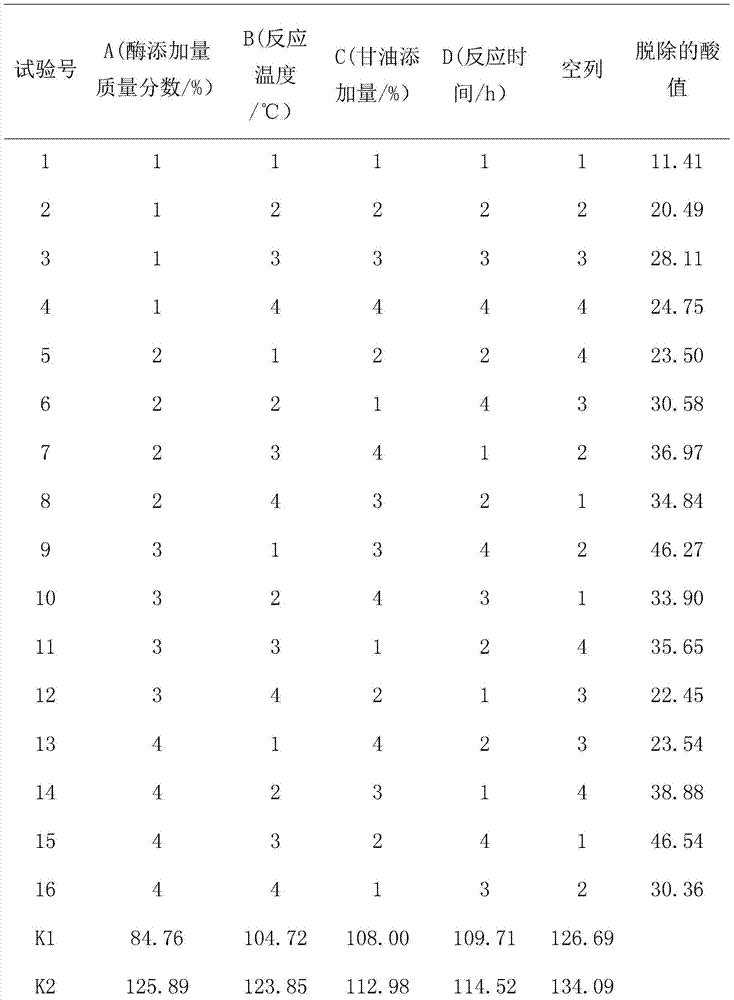

Examples

Embodiment 1

[0034]Firstly, the high-acid value rice bran crude oil is centrifuged at a speed of 4000-5000r / min for 10-15 minutes, and then the centrifuged high-acid value rice bran crude oil is vacuum-filtered using a Buchner funnel to remove the crude rice bran oil. impurities, then stir and heat the high-acid value rice bran crude oil obtained after centrifugation and filtration to 70-80°C, add 0.1%-0.3% of the weight of the high-acid value rice bran crude oil and phosphoric acid with a solubility of 85%, And heat preservation and stirring for 25 to 35 minutes, then add 5% of the weight of high acid value rice bran crude oil in hot water at the same temperature, continue to stir for 50 to 70 minutes, let stand for 3.5 to 4.5 hours, and centrifuge at a speed of 4000 to 5000r / min Degumming in 10-15 minutes to obtain high-acid rice bran oil with an acid value of 39.66mgKOH / g; then, under a vacuum of 0.085MPa, stir and heat the obtained high-acid rice bran oil to 50°C, and add 250% of the th...

Embodiment 2

[0035] Under the vacuum degree of 0.085MPa, stir and heat high-acid rice bran oil with an acid value of 46.41 mgKOH / g to 60°C, add 200% of the theoretical glycerin amount of glycerin, and then add 3% of the oil weight catalyst Lipozyme 435, When the catalytic reaction was performed for 12 hours, the other steps were the same as in Example 1, and the acid value of rice bran oil could be reduced from 46.41 mgKOH / g to 1.87 mgKOH / g.

Embodiment 3

[0037] Under the vacuum degree of 0.085MPa, stir and heat high-acid rice bran oil with an acid value of 49.76 mgKOH / g to 60°C, add 250% of the theoretical glycerin amount of glycerin, and then add 3% of the oil weight catalyst Lipozyme 435, When the catalytic reaction was performed for 12 hours, the other steps were the same as in Example 1, and the acid value of rice bran oil could be reduced from 49.76 mgKOH / g to 1.12 mgKOH / g.

[0038] The enzymatic esterification and deacidification process of high-acid rice bran oil provided by the present invention is to use Lipozyme 435 immobilized lipase to catalyze the esterification reaction of free fatty acids and glycerol in high-acid rice bran oil under a certain degree of vacuum and temperature. Thereby reducing the content of free fatty acids and reducing the acid value of rice bran oil to below 3mgKOH / g; Lipozyme 435 immobilized lipase is food-grade, with mild catalytic conditions and high catalytic efficiency. At the same time, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com