Process for separating and extracting natural ferulic acid with content not more than 98% from wastes in rice bran oil processing

A technology of waste and rice bran oil, which is applied in the separation/purification of carboxylic acid compounds, the preparation of carboxylate, and the preparation of organic compounds, etc. It can solve the problem that the output of natural ferulic acid cannot meet the needs, and achieve easy control of the production process , equipment requires simple, high-purity effect

Inactive Publication Date: 2010-08-25

GUANGXI DAIYUAN VEGETABLE PROD

View PDF2 Cites 28 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to provide a kind of raw material that is easy to obtain and extract process for the problem that the rice bran oil processing waste containing natural ferulic acid precursor is discarded, and the output and quality of natural ferulic acid cannot meet the needs. Simple and reliable, the purity of the extracted natural ferulic acid is up to 98%, and the process of separating and extracting natural ferulic acid from the waste of rice bran oil processing can be carried out in industrial production

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Login to View More

Abstract

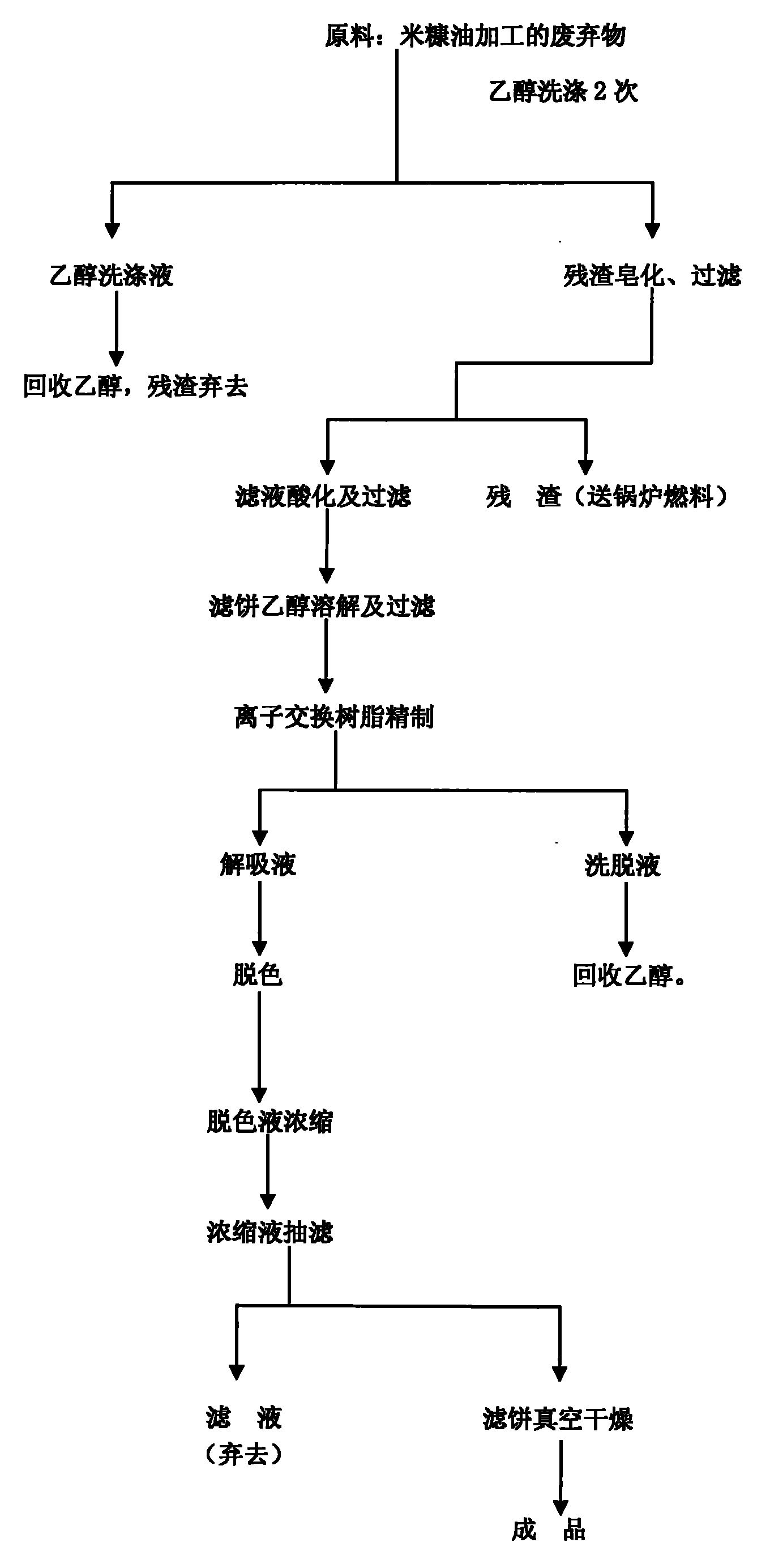

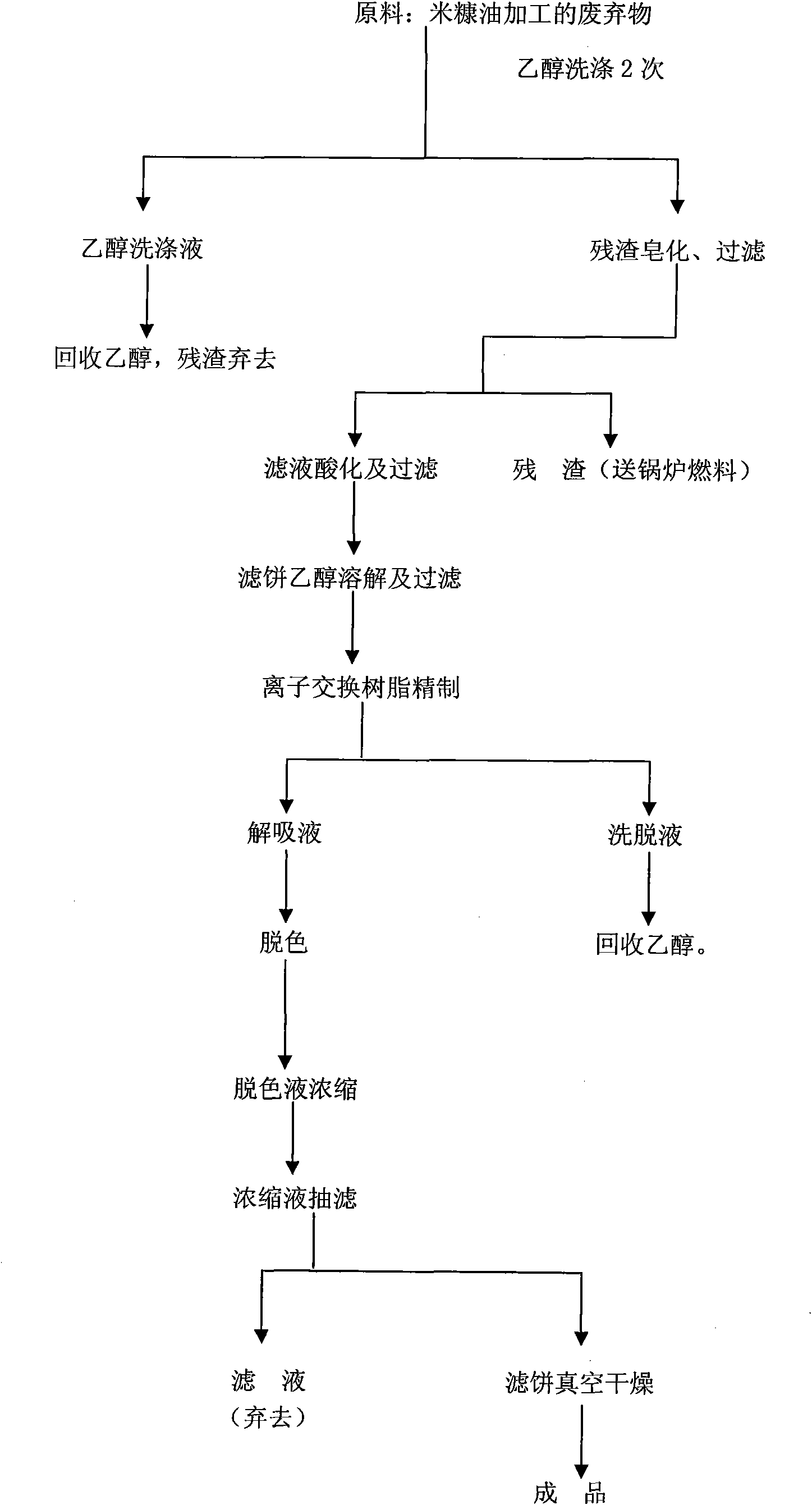

The invention discloses a process for separating and extracting natural ferulic acid with the content not more than 98% from wastes in rice bran oil processing. The process is characterized in that the wastes generated in the rice bran oil processing method are used as raw materials; the process comprises the following steps of: washing by using alcohol, saponificating and filtering, acidifying and filtering, dissolving by using alcohol and filtering, refining by using ion exchange resin, decoloring, concentrating, pumping and filtering, and drying by vacuum to obtain the white powder product with the natural ferulic acid content not more than 98%. The invention has the advantages of easy obtainment of raw materials, utilization of wastes, simple and process, high purity of product by more than 98%, and industrial production.

Description

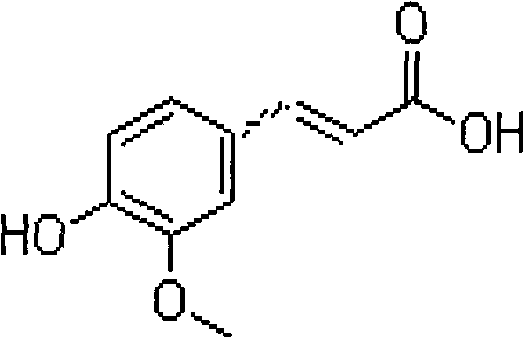

technical field The invention relates to the extraction of natural ferulic acid, in particular to a process for separating and extracting natural ferulic acid with a content greater than or equal to 98% from rice bran oil processing waste. Background technique Ferulic acid is one of the derivatives of cinnamon acid. There are two types, cis and trans. The cis is a yellow oil, and the trans is a white to slightly yellow powder. It generally refers to the trans. The relative molecular mass is 194.19, and the melting point is 174°C. Ferulic acid has anti-platelet aggregation, inhibits the release of platelet 5-hydroxytryptamine, inhibits the generation of platelet thromboxane A2 (TXA2); enhances the activity of prostaglandins; removes nitrite, oxygen free radicals, and peroxynitroso; antibacterial, anti-inflammatory, Anti-tumor, anti-mutation; enhance human immune function, enhance human sperm vitality and motility, etc. It can be used as the basic raw material of drugs for ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07C59/64C07C51/42C07C51/487

Inventor 刘庚贵周迪平唐克军曾润清蒋新芳

Owner GUANGXI DAIYUAN VEGETABLE PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com