Process for using latter admixing method to produce green concrete

A technology of concrete and post-mixing, which is applied in the direction of sustainable waste treatment, solid waste management, and climate sustainability. It can solve the problems of long setting time and low activity, and achieve fast setting time, stable quality and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

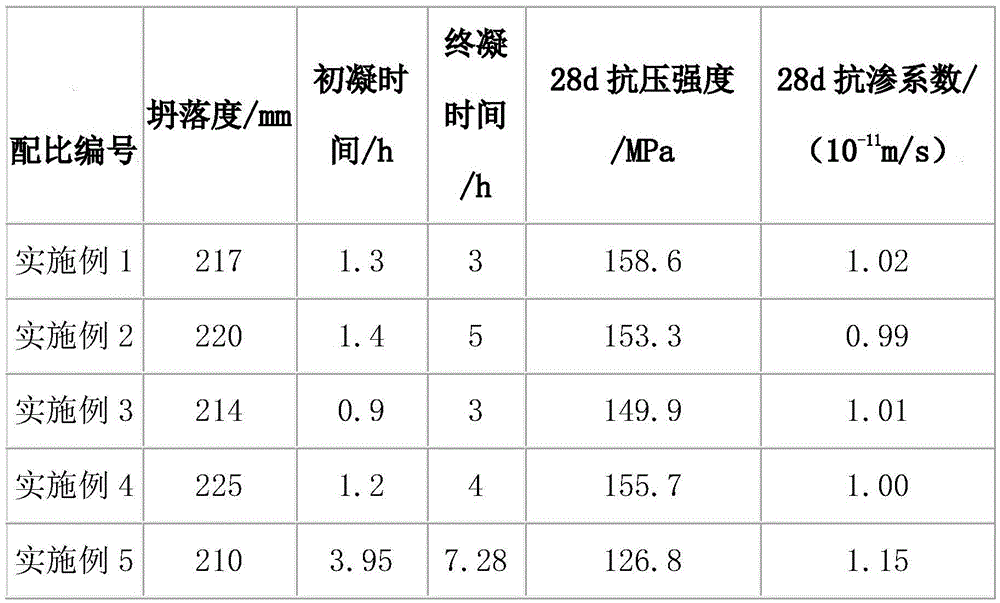

Examples

Embodiment 1

[0028] A method for producing green concrete with post-mixing method, characterized in that the steps are as follows:

[0029] (1) Prepare concrete admixture:

[0030] Add polyether macromonomer and sulfonate in water, raise the temperature to 60°C, sulfonate for half an hour, add the initiator, add acrylic acid monomer dropwise while stirring, control the dropping time at 45 minutes, keep the temperature for one hour after dropping, and cool down To 45°C, add alcohol amine dropwise, the dropping time is controlled at 50 minutes, and the finished product is finished at a constant temperature of 50°C for one hour;

[0031] The mass ratio of described sulfonate and polyether macromonomer is 1:3,

[0032] The mass ratio of described initiator and polyether macromonomer is 1:2.5;

[0033] Prepare an environmentally friendly colorless transparent liquid concrete admixture;

[0034] (2) Preparation of modified oil palm husk ash:

[0035] Grind the remaining raw ash after the bur...

Embodiment 2

[0043] A method for producing green concrete with post-mixing method, characterized in that the steps are as follows:

[0044] (1) Prepare concrete admixture:

[0045] Add polyether macromonomer and sulfonate in water, raise the temperature to 60°C, sulfonate for half an hour, add the initiator, add acrylic acid monomer dropwise while stirring, control the dropping time at 45 minutes, keep the temperature for one hour after dropping, and cool down To 45°C, add alcohol amine dropwise, the dropping time is controlled at 50 minutes, and the finished product is finished at a constant temperature of 50°C for one hour;

[0046] The mass ratio of described sulfonate and polyether macromonomer is 1:3,

[0047] The mass ratio of described initiator and polyether macromonomer is 1:2.5;

[0048] Prepare an environmentally friendly colorless transparent liquid concrete admixture;

[0049] (2) Preparation of modified oil palm husk ash:

[0050] Grind the remaining raw ash after burning...

Embodiment 3

[0058] A method for producing green concrete with post-mixing method, characterized in that the steps are as follows:

[0059] (1) Prepare concrete admixture:

[0060] Add polyether macromonomer and sulfonate in water, raise the temperature to 60°C, sulfonate for half an hour, add the initiator, add acrylic acid monomer dropwise while stirring, control the dropping time at 45 minutes, keep the temperature for one hour after dropping, and cool down To 45°C, add alcohol amine dropwise, the dropping time is controlled at 50 minutes, and the finished product is finished at a constant temperature of 50°C for one hour;

[0061] The mass ratio of described sulfonate and polyether macromonomer is 1:3,

[0062] The mass ratio of described initiator and polyether macromonomer is 1:2.5;

[0063] Prepare an environmentally friendly colorless transparent liquid concrete admixture;

[0064] (2) Preparation of modified oil palm husk ash:

[0065] Grind the remaining raw ash after the bur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com