Method for thermally modifying wood by oil palm oil

A technology of oil palm oil and thermal modification, which is applied in the field of thermally modified wood with oil palm oil, can solve the problem that the flexural strength and impact toughness of thermally modified wood are reduced, the scope of use of thermally modified wood is limited, and it is difficult to tenon It can solve problems such as furniture with a 900-foot structure, and achieve the effect of fast heat transfer, convenient industrial application, and shortened processing cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The present invention is further illustrated below with non-limiting examples. Embodiment one: oil palm oil thermally modified rubber wood

[0014] 1) Take rubber wood gauge timber with a moisture content of 20% and a thickness of 3.5 cm, stack it firmly, and put it into a treatment tank.

[0015] 2) Heat the oil palm oil to 180°C, and then inject it into the treatment tank through the valve to continuously supply heat to the oil palm oil and heat the wood.

[0016] 3) After the wood temperature reaches 180°C, increase the oil temperature to increase the wood temperature at a rate of 20°C / h, and when the wood temperature reaches 200°C, maintain for 3 hours to thermally modify the wood.

[0017] 4) Stop the heat supply, immediately discharge the high-temperature palm oil from the treatment tank, inject atomized water to gradually cool the wood to 130°C, wait for it to cool down to room temperature naturally, and the treatment is completed, open the treatment tank, and u...

Embodiment 2

[0018] Embodiment 2 Oil palm oil thermally modified acacia mazhan

[0019] 1) Take acacia timber with a moisture content of 12-15°C and a thickness of 3.0 cm, stack it firmly, and put it into a treatment tank.

[0020] 2) Heat the oil palm oil to 155°C, and then inject it into the treatment tank through the valve to continuously supply heat to the oil palm oil and heat the wood.

[0021] 3) After the wood temperature reaches 180°C, increase the oil temperature to increase the wood temperature at a rate of 15°C / h, and when the wood temperature reaches 200°C, keep the wood for 2 hours for thermal modification.

[0022] Cooling process is identical with embodiment one;

Embodiment 3

[0023] Embodiment three: thermally modified lychee wood with oil palm oil

[0024] 1) Take lychee timber with a moisture content of less than 12% and a thickness of 2.5 cm, stack it firmly, and put it into a treatment tank.

[0025] 2) Heat the oil palm oil to 150°C, and then inject it into the treatment tank through the valve to continuously supply heat to the oil palm oil and heat the wood.

[0026] 3) After the wood temperature reaches 180°C, increase the oil temperature to increase the wood temperature at a rate of 10°C / h. When the wood temperature reaches 200°C, keep the oil for 3 hours for thermal modification.

[0027] Cooling process is identical with embodiment one;

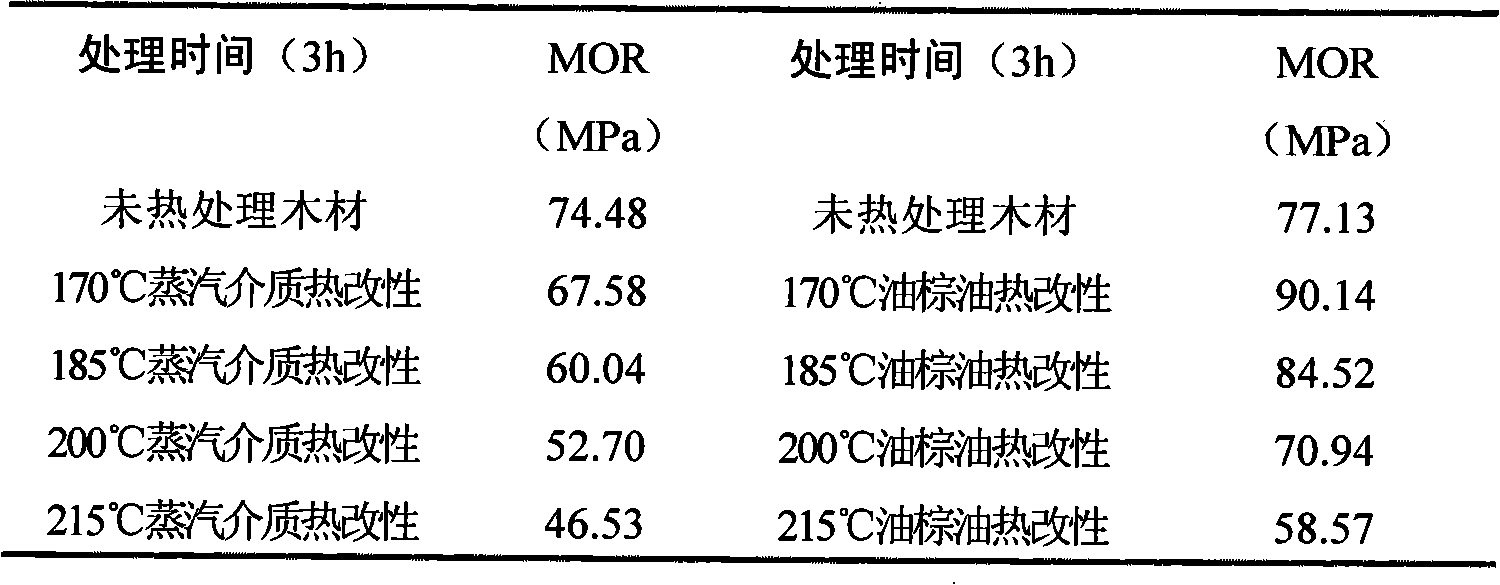

[0028] According to the national standard "GB1936.1-91 Test method for flexural strength of wood", the mechanical properties of rubber wood steam heat-treated and oil palm oil heat-treated materials obtained by testing different treatment temperatures for 3 hours are shown in Table 1. Compared with rubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com