Method for producing special large-particle slow release fertilizer for oil palm

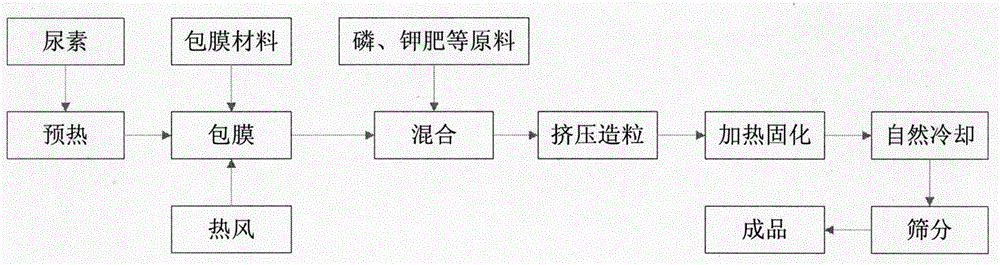

A production method and technology of slow-release fertilizer, which are applied in the field of special slow-release fertilizer for large-particle oil palm, can solve the problems of inconvenient operation and inability to supply, and achieve the effects of uniform particles, less material return and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0024] Configuration of coating material: 3.5 kg of ethylene glycol dimethacrylate, 25 kg of methyl methacrylate, 5 kg of butyl methacrylate, 1 kg of neoprene, ethylene glycol-maleic anhydride unsaturated polyester Mix 0.25 kg, 15 kg of styrene, 0.075 kg of paraffin, and 1.5 kg of benzoyl peroxide paste for use.

[0025] First, add 299 kg of granular urea preheated to 80 degrees into the drum coater. After the material is rotated evenly and continuously, the above-mentioned coating material is evenly added for coating; after the coating is completed, 114 kg of monoammonium phosphate (containing Nitrogen 11%, phosphorus pentoxide 44%), bitter soil 58.6 kg (magnesium oxide content 70%), potassium chloride 417 kg (potassium oxide content 60%), copper sulfate pentahydrate 21 kg (containing copper sulfate pentahydrate 95 %), 15 kg of borax (containing 95% of borax), and 24 kg of zinc sulfate heptahydrate (containing 95% of zinc sulfate heptahydrate), mix them evenly, and add the mi...

example 2

[0027] Configuration of coating material: 5 kg of ethylene glycol dimethacrylate, 30 kg of methyl methacrylate, 7 kg of butyl methacrylate, 2 kg of neoprene, ethylene glycol-maleic anhydride unsaturated polyester Mix 0.5 kg, 20 kg of styrene, 0.05 kg of paraffin, and 1 kg of benzoyl peroxide paste for use.

[0028] First, add 272 kg of granular urea preheated to 75 degrees into the drum coater, adjust the angle and rotation speed of the drum coater to make the material flow and distribute evenly, and then evenly add the above-mentioned coating material for coating; Then, 228 kg of monoammonium phosphate (containing 11% nitrogen and 44% phosphorus pentoxide), 40.35 kg of bitter soil (75% of magnesium oxide), 334 kg of potassium chloride (60% of potassium oxide), and pentahydrate were added in turn. 21 kg of copper sulfate (containing 95% copper sulfate pentahydrate), 15 kg of borax (containing 95% of borax), and 24 kg of zinc sulfate heptahydrate (containing 95% of zinc sulfate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com