Method for producing desulfurized sugar by high efficiency active carbon improved sufurous acid method sugar producing process

A sulfurous acid method and activated carbon technology, which is applied in the direction of using adsorbent purification, oxidation/reduction purification, etc., can solve the problem of few breakthroughs, and achieve the effect of saving capital investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

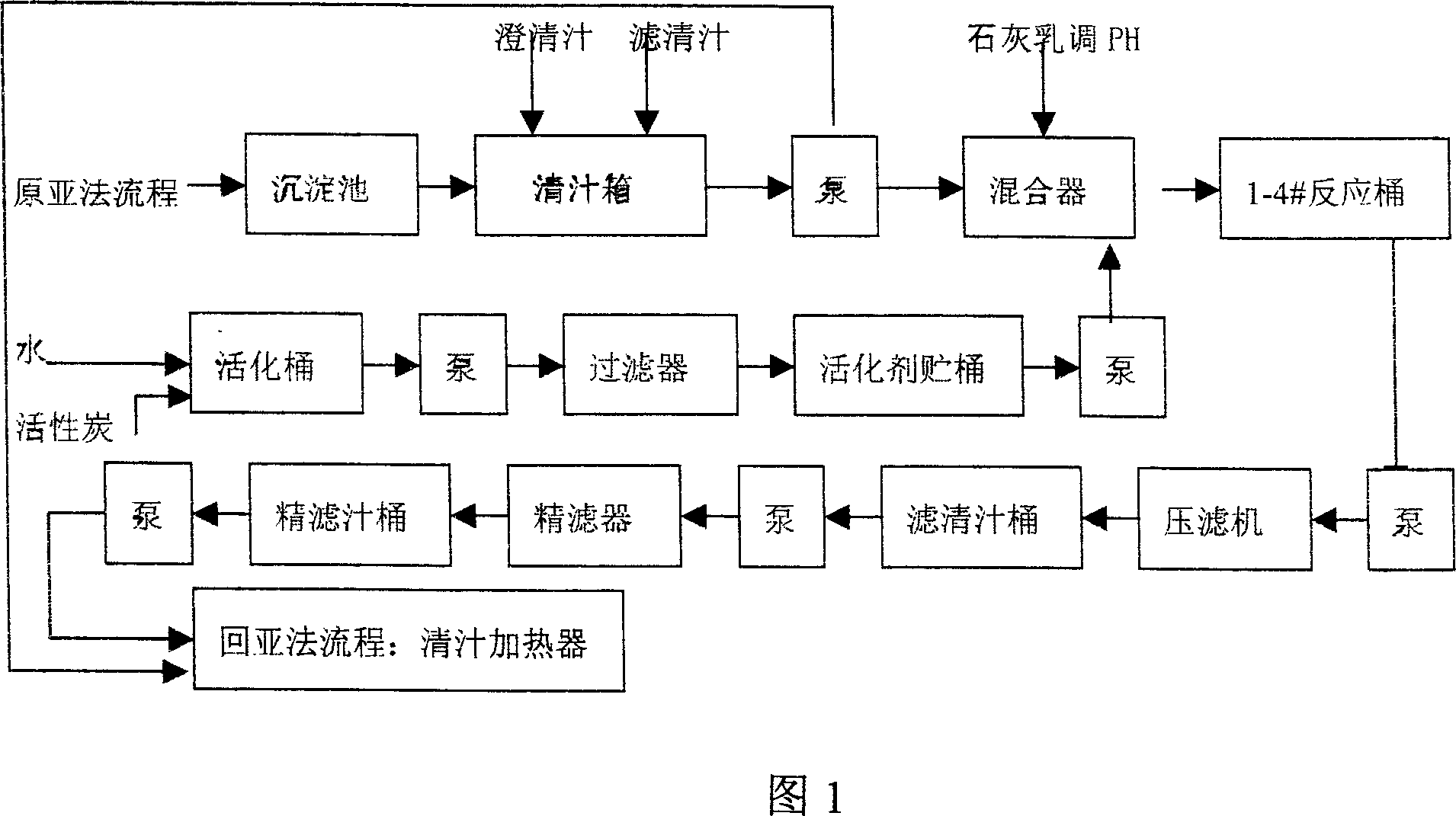

Embodiment 1

[0012] The sugarcane mixed juice (unclarified) with a purity of 80.15AP (simplified purity) is treated by the common sulfite method (that is, the mixed juice is treated by adding ash, phosphoric acid, heating, and clarification in a sedimentation tank, which belongs to the prior art), Most of the non-sugar and pigment are removed to obtain ordinary clear juice with a purity of 81.7AP and a color value of 1980IU. Pump the ordinary clear juice into the mixer, add the diluted and activated sugar and mix it with the ordinary clear juice with high-efficiency activated carbon, add lime milk to adjust the pH value to 6.8-7.6, and then go through the adsorption of the reaction barrel for 20-30min to further remove the The non-sugar and pigment; the obtained clear juice is sent to the plate and frame filter press to remove the filter mud to obtain the filtered juice, and the filtered juice is filtered through the fine filter to obtain the fine filtered clear juice with better quality, t...

Embodiment 2

[0015] The basic steps and method are the same as in Example 1, except that the consumption of high-efficiency activated carbon for sugar is 0.1% of that of common clear juice.

Embodiment 3

[0017] The basic steps and method are the same as in Example 1, except that the consumption of high-efficiency activated carbon for sugar is 0.2% of that of common clear juice.

[0018] project

indicators

premium product

first grade

Secondary product

quality

quantity

Method A caramel decolorization rate, %≥

110

100

90

Methylene blue decolorization power (1.5g / L), mL / 0.1g≥

13.0

12.0

11.0

Ash content, %≤

12.0

12.0

12.0

Iron content, %≤

0.05

0.10

0.15

Chloride content, %≤

0.20

0.25

0.30

Moisture, %≤

35

35

35

PH value

3.0~5.0

3.0~5.0

3.0~5.0

[0019] Wherein, the preparation method of high-efficiency activated carbon for sugar is as follows:

[0020] 1. Use bagasse as raw material, break up the bagasse and send it to the side of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com