Method for preparing bagasse carbon material by hydrothermal method and application thereof

A technology of bagasse carbon and hydrothermal method, which is applied in the fields of application, carbon preparation/purification, chemical instruments and methods, etc., can solve the problems of strong corrosion, difficult waste acid treatment, etc., and achieve environmental protection, no pollution in the process, material easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

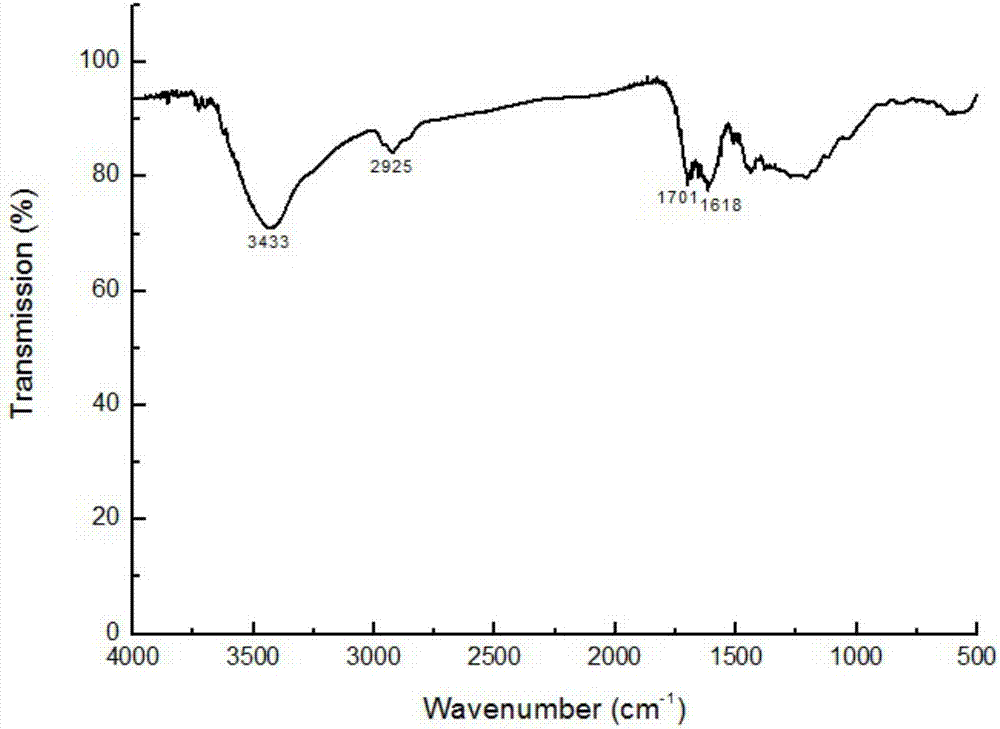

Embodiment 1

[0023] The waste bagasse is cut into small sections less than 10 cm in length, dried and crushed to obtain bagasse powder. Pass the bagasse powder through a 90-mesh sieve, mix it evenly with distilled water at a mass ratio of 1:19, and carry out hydrothermal carbonization reaction in a hydrothermal reaction kettle. The hydrothermal carbonization temperature is 240°C and the time is 10h. After the reaction, the solid was obtained by suction filtration and washed with distilled water several times. The washed solids are collected, dried and ground, and passed through a 90-mesh sieve to obtain hydrothermal carbon materials.

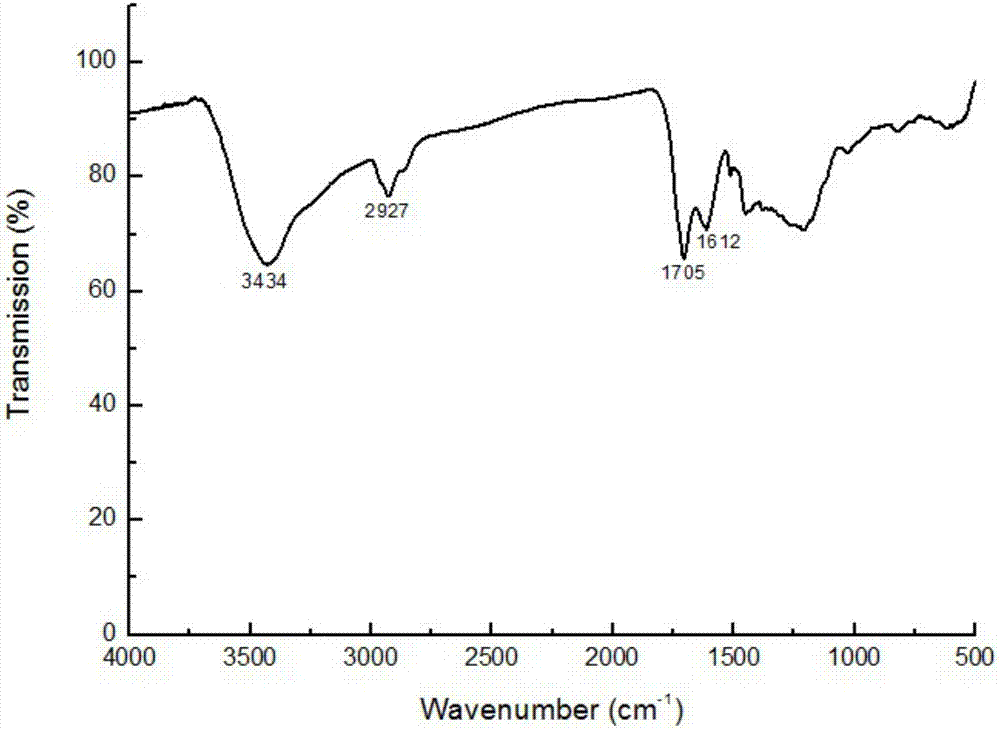

Embodiment 2

[0025] The waste bagasse is cut into small sections less than 10 cm in length, dried and crushed to obtain bagasse powder. Pass the bagasse powder through a 90-mesh sieve, mix it evenly with 1.0v% acrylic acid according to the ratio of solid-liquid mass ratio of 1:19, and carry out hydrothermal carbonization reaction in a hydrothermal reaction kettle. The hydrothermal carbonization temperature is 240°C, and the time is It is 10h. After the reaction, the solid was obtained by suction filtration and washed with distilled water several times. The washed solids are collected, dried and ground, and passed through a 90-mesh sieve to obtain hydrothermal carbon materials.

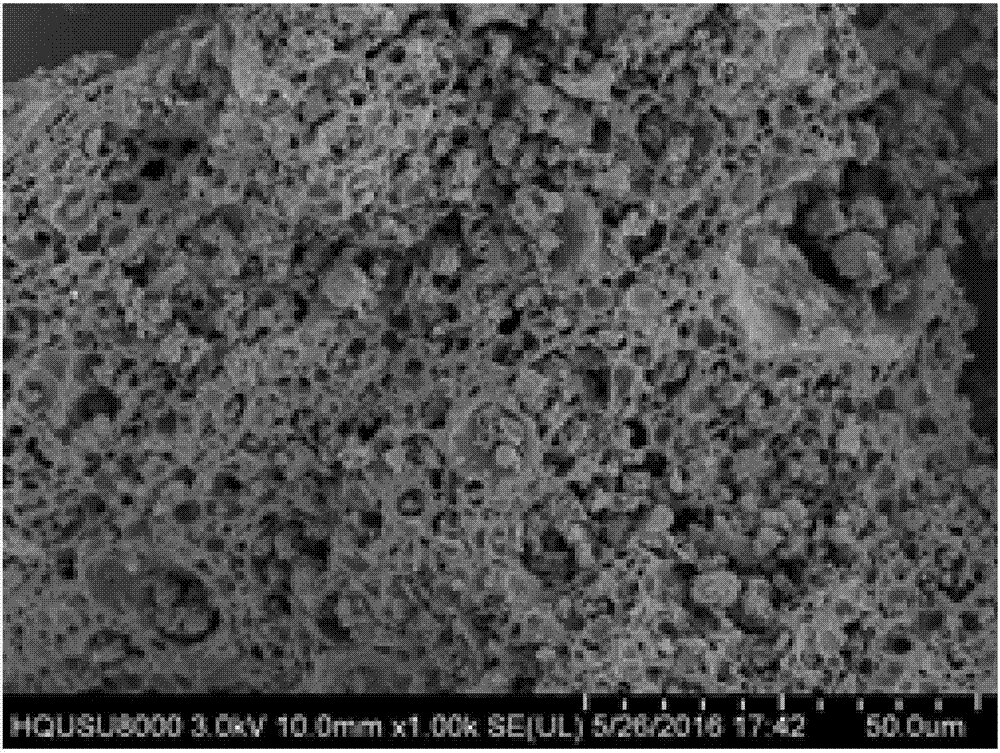

Embodiment 3

[0027] The waste bagasse is cut into small sections less than 10 cm in length, dried and crushed to obtain bagasse powder. Pass the bagasse powder through a 90-mesh sieve, mix evenly with 40wt% phosphoric acid according to the solid-to-liquid mass ratio of 1:19, and carry out hydrothermal carbonization reaction in a hydrothermal reaction kettle. The hydrothermal carbonization temperature is 260°C, and the time is 12h. After the reaction, wash with hot distilled water several times until neutral. The washed solids are collected, dried and ground, and passed through a 90-mesh sieve to obtain hydrothermal carbon materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com