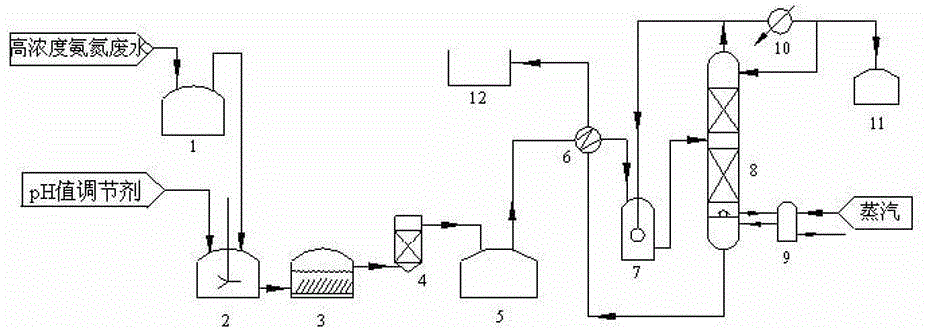

Treatment process for high-concentration ammonium-nitrogen waste water

An ammonia nitrogen wastewater treatment technology, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of easy scaling and blockage of tower equipment, high operating costs, and high tower body. To solve the problem of fouling of tower equipment, improve the efficiency of mass transfer and heat transfer, and reduce the volume of tower equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

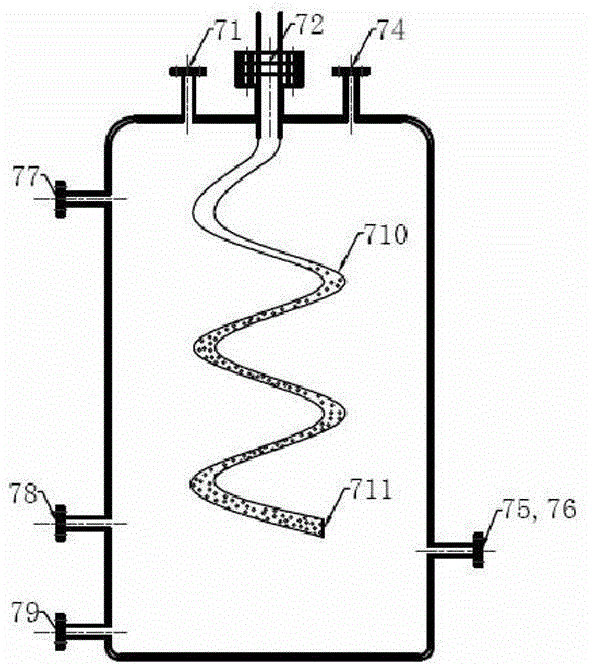

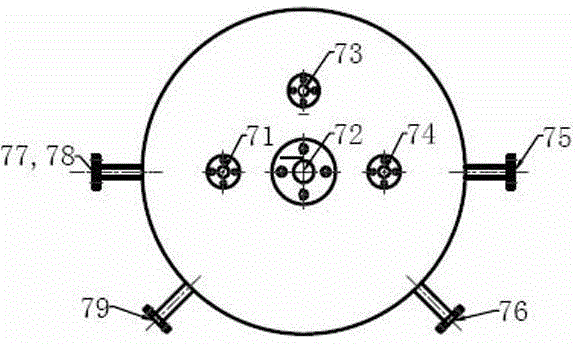

Method used

Image

Examples

Embodiment 1

[0037]A treatment process for high-concentration ammonia-nitrogen wastewater of the present invention, wherein, in the high-concentration ammonia-nitrogen wastewater to be treated, the concentration of ammonia nitrogen is 5000mg / L, Cl - The concentration is 330mg / L, HCO 3 - The concentration is 4250mg / L, the wastewater temperature is 22°C, the pH value is 7.9, and the treatment capacity is 10m 3 / h. The treatment process includes the following steps:

[0038] (1) Pretreat the high-concentration ammonia-nitrogen wastewater to be treated. The specific process is: first homogenize the high-concentration ammonia-nitrogen wastewater, and then use sodium hydroxide (calcium hydroxide, sodium carbonate or sodium bicarbonate, etc. alkaline regulator) to adjust the pH value to 11, and then precipitate and filter to obtain pretreated ammonia nitrogen wastewater.

[0039] (2) Heat the pretreated ammonia nitrogen wastewater to 61°C first, and then perform concentration and temperature ...

Embodiment 2

[0060] A treatment process for high-concentration ammonia-nitrogen wastewater of the present invention can adopt the treatment system of embodiment 1, wherein, in the high-concentration ammonia-nitrogen wastewater to be treated, the concentration of ammonia nitrogen is 10000 mg / L, Cl - Concentration 120mg / L, SO 4 2- The concentration is 8400 mg / L, the temperature is 26°C, the pH value is 6.2, and the treatment capacity is 10m 3 / h. The treatment process includes the following steps:

[0061] (1) Pretreat the high-concentration ammonia-nitrogen wastewater to be treated. The specific process is: first homogenize the high-concentration ammonia-nitrogen wastewater, then use sodium hydroxide to adjust the pH value to 11.2, and then carry out precipitation and filtration to obtain pretreatment After ammonia nitrogen wastewater.

[0062] (2) Heat the pretreated ammonia nitrogen wastewater to 64°C first, and then carry out concentration and temperature increase treatment, so that ...

Embodiment 3

[0069] A treatment process for high-concentration ammonia-nitrogen wastewater of the present invention can adopt the treatment system of embodiment 1, wherein, in the high-concentration ammonia-nitrogen wastewater to be treated, the concentration of ammonia nitrogen is 13500mg / L, SO 4 2- The concentration is 4200 mg / L, the wastewater temperature is 28°C, the pH value is 6.7, and the treatment capacity is 10m 3 / h. The treatment process includes the following steps:

[0070] (1) Pretreat the high-concentration ammonia-nitrogen wastewater to be treated. The specific process is: first homogenize the high-concentration ammonia-nitrogen wastewater, then use sodium hydroxide to adjust the pH value to 11, and then carry out precipitation and filtration to obtain pretreatment After ammonia nitrogen wastewater.

[0071] (2) Heat the pretreated ammonia nitrogen wastewater to 66°C first, and then carry out concentration and temperature increase treatment, so that the concentration of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com