Ammonia-carbon separation process

A technology for ammonia-carbon separation and carbon separation, which is applied in the direction of ammonia preparation/separation, separation method, dispersed particle separation, etc., can solve the problems of high energy consumption, ammonia and carbon dioxide cannot be completely separated, etc., to increase economic benefits and reduce Effect of liquid circulation volume and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

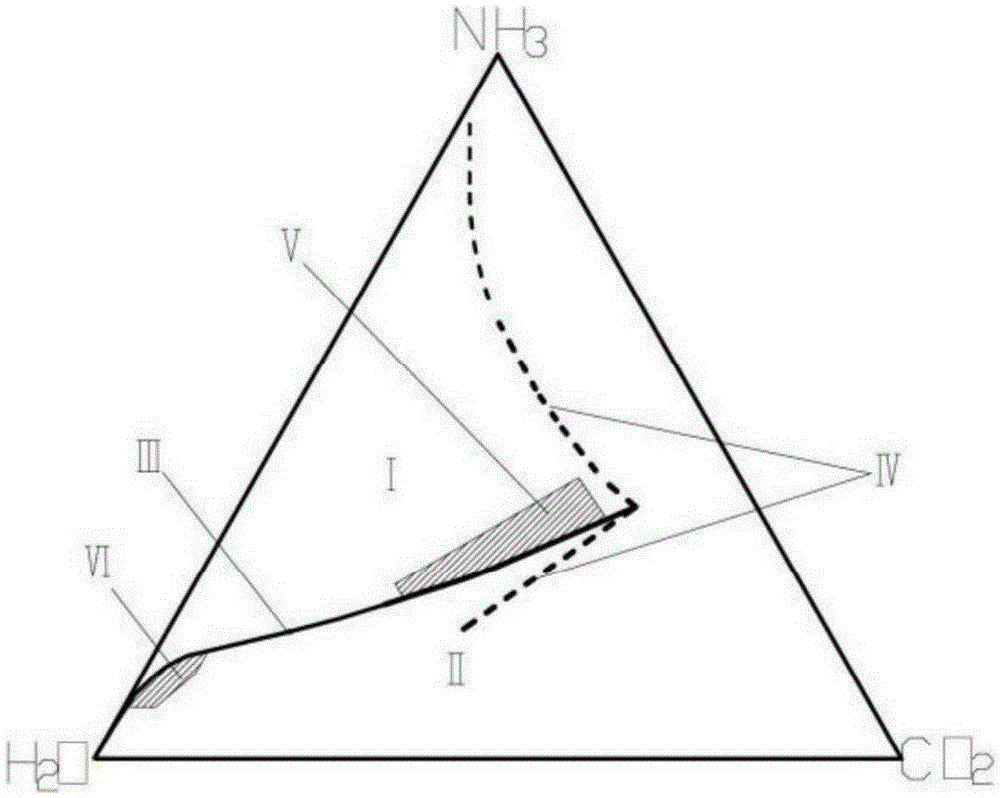

Method used

Image

Examples

Embodiment 1

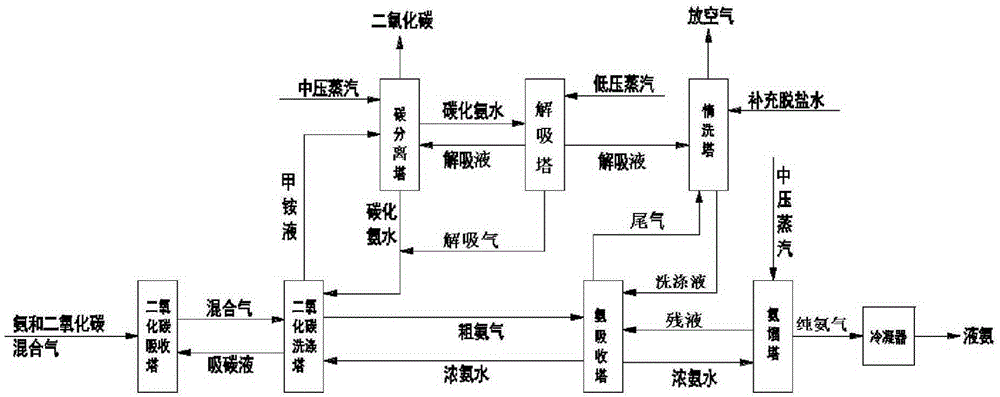

[0052] The ammonia-carbon separation process described in the present embodiment comprises the following steps:

[0053] Carbon dioxide absorption step: the mixed gas of ammonia and carbon dioxide enters the carbon dioxide absorption tower from the bottom, and there is a carbon absorbing liquid from the carbon dioxide scrubber at the top of the tower, and the gas and liquid in the tower are in countercurrent contact, and more than 60% of the carbon dioxide is absorbed into the liquid phase and is not absorbed The mixed gas continues to flow upwards and enters the carbon dioxide scrubber. The top of the tower is filled with concentrated ammonia water from the ammonia absorption tower. In the tower, there is carbonized ammonia water condensed by the air cooler from the carbon separation tower and the desorption tower. Water removes the heat of carbon dioxide dissolution reaction in time. The top of the carbon dioxide washing tower obtains crude ammonia with a temperature of 25-4...

Embodiment 2

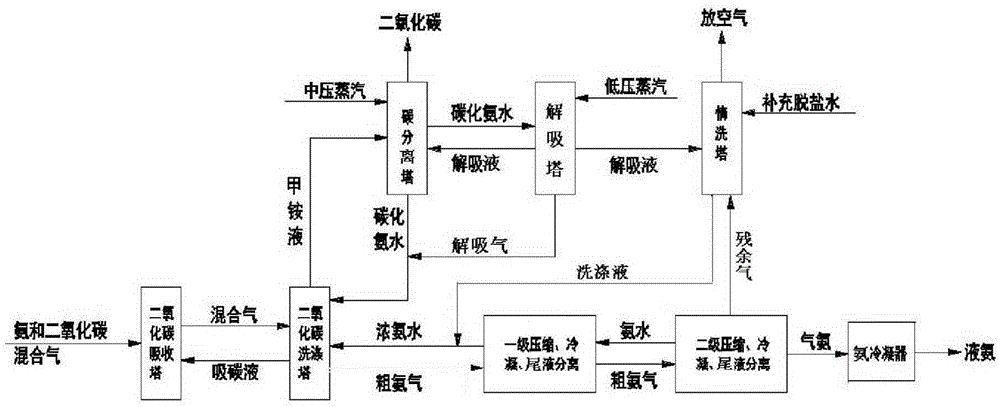

[0059] In the ammonia-carbon separation process described in this embodiment, the absorption and separation steps of carbon dioxide are the same as in Example 1, and also include ammonia refining steps:

[0060] The crude ammonia gas is sent to the two-stage compressor, the outlet pressure of the first stage is 0.5MPaG, and the outlet pressure of the second stage is 1.7MPaG. The gas compressed by each stage is condensed with circulating water and the tail liquid is separated. , and finally obtain gaseous ammonia with a pressure of not less than 1.5MPaG and a water content of less than 0.1wt%. The gaseous ammonia is sent to the ammonia condenser, and the pure liquid ammonia is obtained through the condensed phase of circulating water, while the residual gas enters the inert washing tower and is desorbed with the desorption liquid. Wash the air until the ammonia content is less than 50ppm, and return the bottom liquid of the inert washing tower and the compressed tail liquid to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com