Preparation method of linen flat-strip fabric

A linen and fabric technology, applied in the field of linen weaving and weaving, can solve problems such as lack of patterns and colors, single variety of linen weaving fabrics, and insufficient fashion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073]Embodiment 1: a kind of preparation method of linen hidden strip fabric, described preparation method comprises the steps:

[0074] 1. Select flax raw flax with a split degree greater than or equal to 250 to make flax roving;

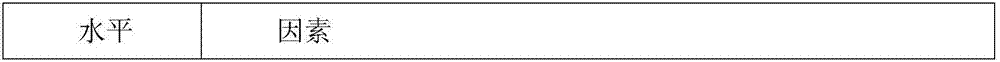

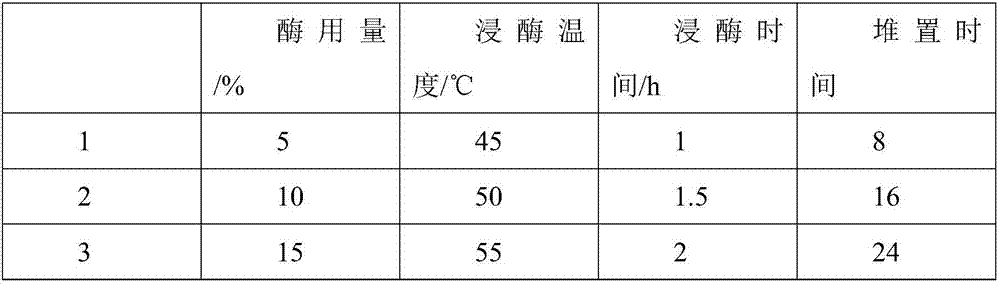

[0075] 2. Then, the flax roving is degummed through biological enzyme treatment. The biological enzyme treatment includes sequentially processing the burlap sliver through compound enzyme treatment, stacking, pickling, sub-bleaching, alkali washing, oxygen bleaching, and water washing; The compound enzyme treatment is to process pectinase, lipase, xylanase, and cellulase according to the mass ratio of 2:2:1:1 and then undergo a fermentation treatment to obtain a crude enzyme solution for preliminary degumming of the hemp strips treatment, and then pectinase, lipase, xylanase, and cellulase are fermented three times according to the mass ratio of 3:1:2:1 to obtain high-efficiency enzyme liquid. Secondary degumming treatment, the alkali washing use...

Embodiment 2

[0079] Embodiment 2: a kind of preparation method of flax hidden strip fabric, described preparation method comprises the steps:

[0080] 1. Select flax raw flax with a split degree greater than or equal to 250 to make flax roving;

[0081] 2. Then, the flax roving is degummed through biological enzyme treatment. The biological enzyme treatment includes sequentially processing the burlap sliver through compound enzyme treatment, stacking, pickling, sub-bleaching, alkali washing, oxygen bleaching, and water washing; The compound enzyme treatment is to process pectinase, lipase, xylanase, and cellulase according to the mass ratio of 2:2:1:1 and then undergo a fermentation treatment to obtain a crude enzyme solution for preliminary degumming of the hemp strips treatment, and then pectinase, lipase, xylanase, and cellulase are fermented three times according to the mass ratio of 3:1:2:1 to obtain high-efficiency enzyme liquid. Secondary degumming treatment, the alkali washing use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com