Tenter oven and manufacturing method for stretched film

An oven and tenter technology, applied in drying, dryer, flat products and other directions, can solve the problem of uneven heat transfer efficiency, and achieve the effects of reducing power consumption, reducing air volume, and improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

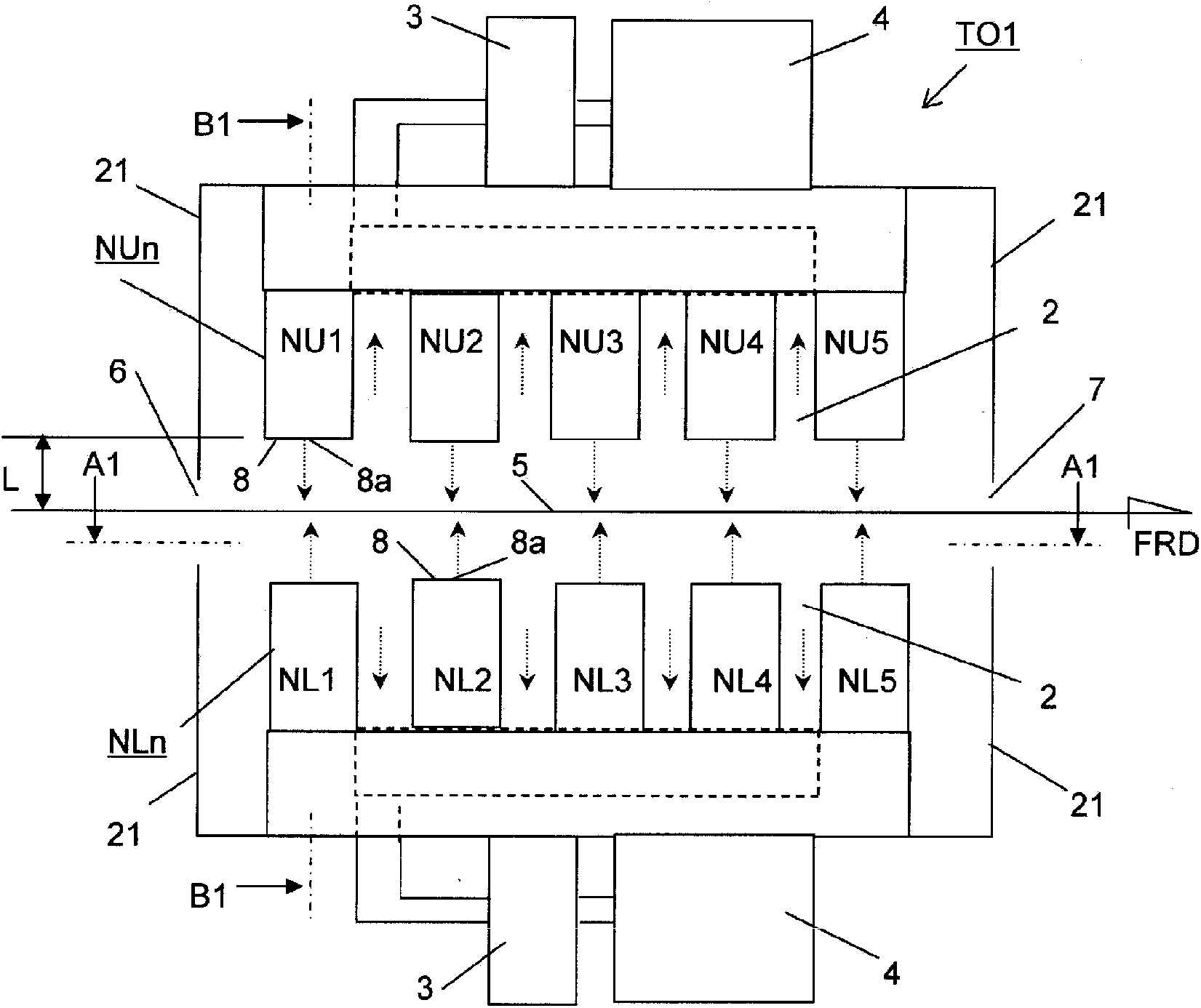

[0158] First, a method for evaluating the effects of the present invention will be described.

[0159] (1) Measurement method of MD flow

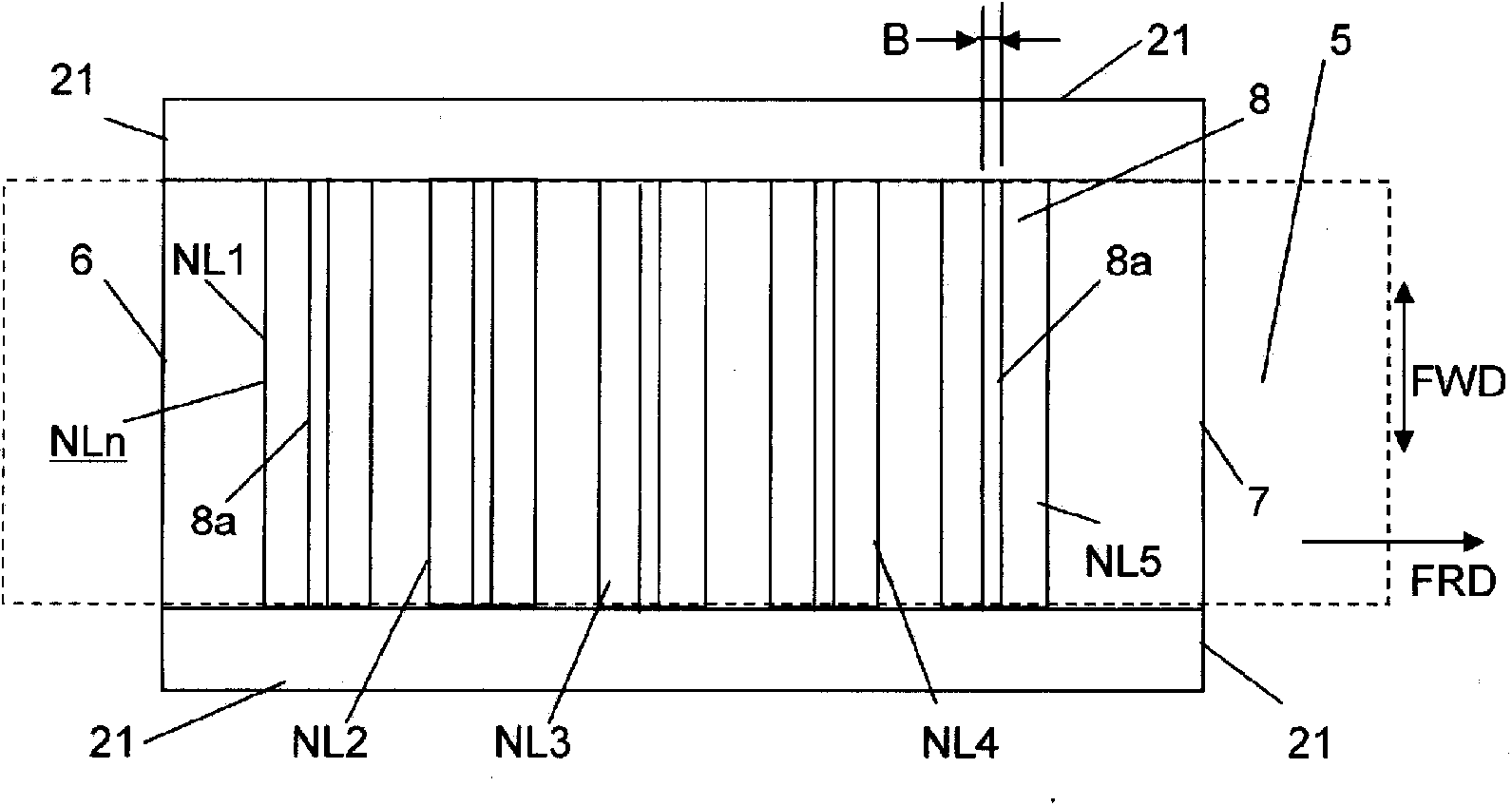

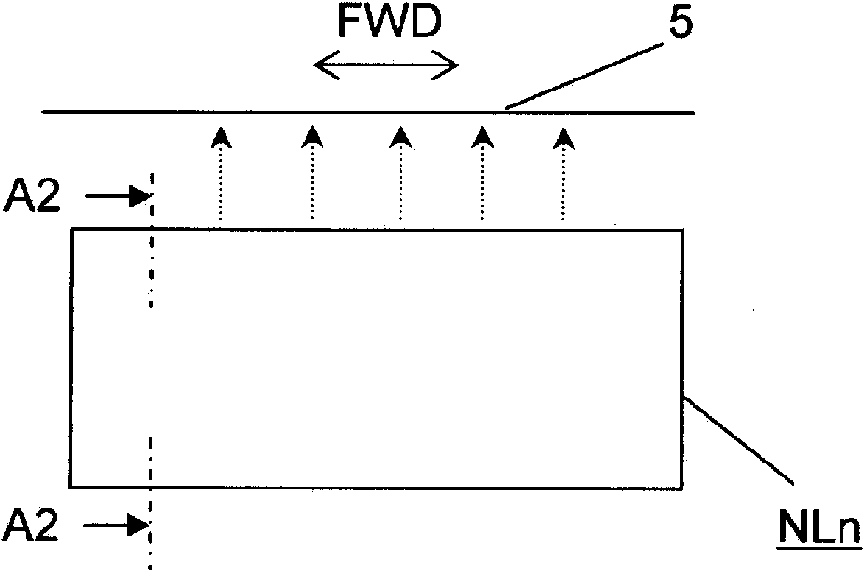

[0160] A model tester modeled as a chamber constituting the tenter oven of the present invention was produced, and the MD flow was measured using the model tester. Figure 8 It is a schematic diagram of the longitudinal section of the model testing machine. In order to carry out the test easily and cheaply, as a substitute for the thermoplastic resin film, a transparent acrylic plate 17 with a length of 2.0 m in the direction of travel of the film and a width of 1.8 m in the width direction of the travel film was fixed at the position of the film passing surface 5 .

[0161] The internal shape and dimensions of the chamber of the model testing machine were 1.8 m in length in the running direction of the film, 1.8 m in width in the width direction of the running film, and 1.5 m in height.

[0162] on the model testing machine Figure 8 T...

Embodiment 2

[0180] The wind speed [m / s] and the heating efficiency [W / m 2 K], uneven temperature [°C]. The results are shown in Table 1.

Embodiment 3

[0182] The wind speed [m / s] and the heating efficiency [W / m 2 K], uneven temperature [°C]. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com