Process for preparing powdered soy bean phosphatide

A soybean lecithin and powder technology, which is applied in the fields of edible phospholipid composition, food science, protein food ingredients, etc., can solve the problems of continuous separation of materials, low product yield, and low product yield, etc., and achieves high labor intensity and high output. Low, low solvent loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

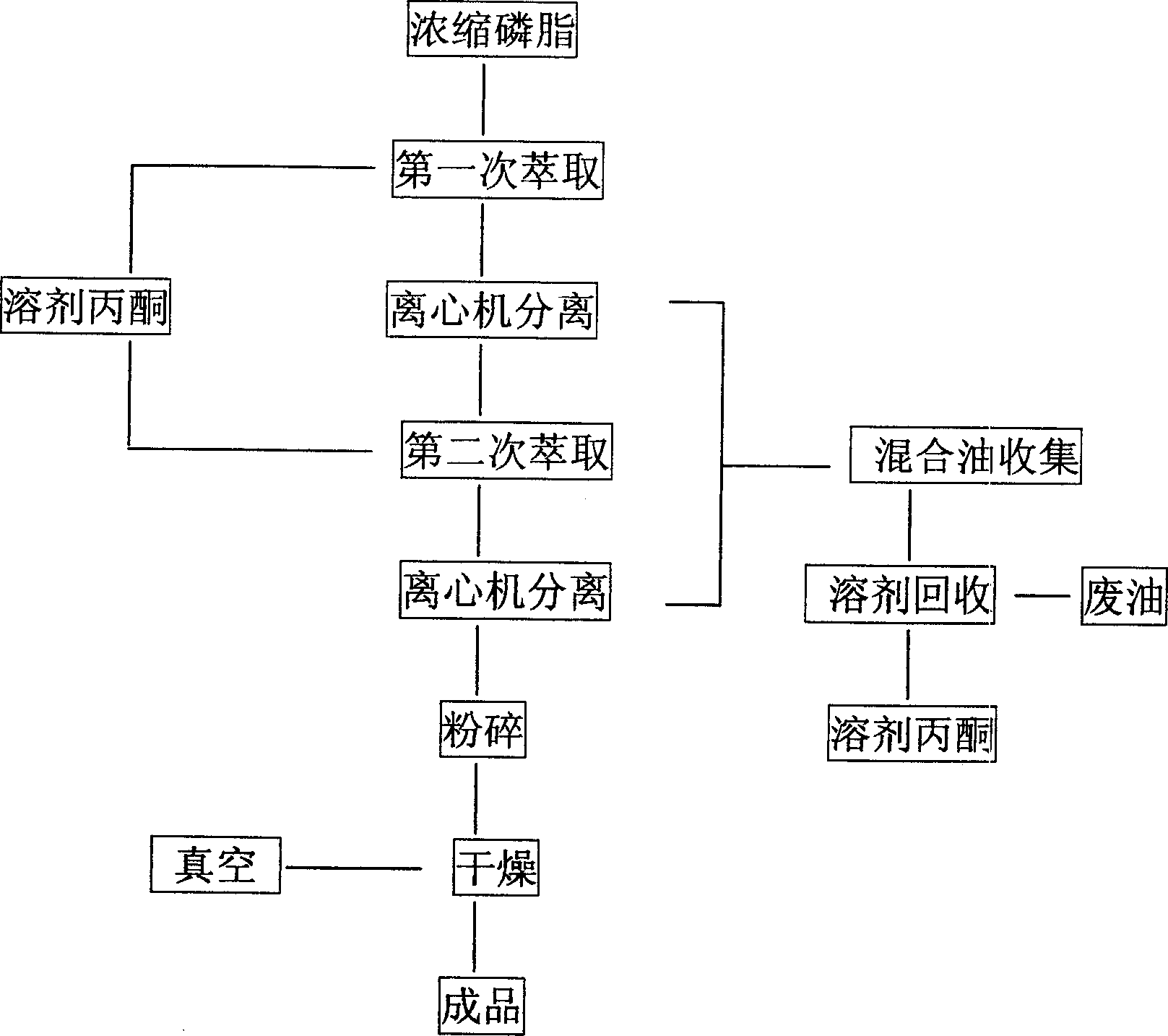

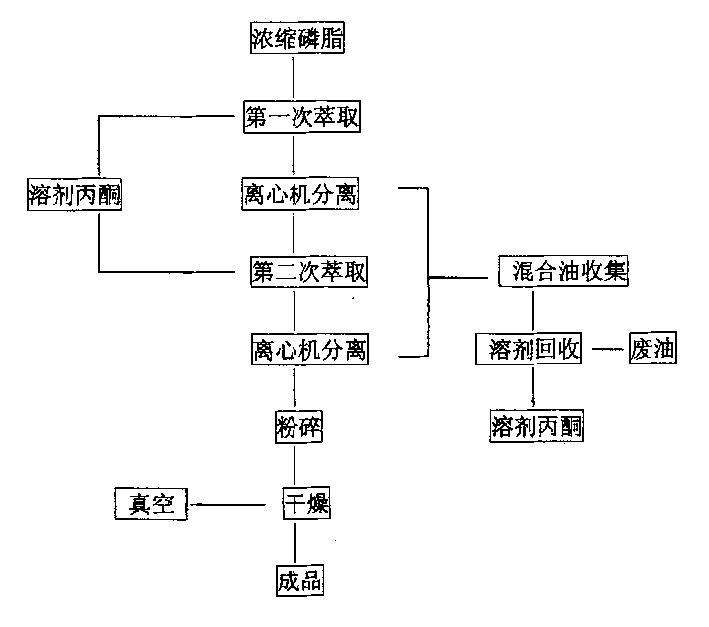

[0027] Embodiment 1: With reference to accompanying drawing, preparation method comprises the following steps, the acetone in the acetone storage tank is pumped in the extraction mixing tank once by the ratio of concentrated phospholipid and acetone 1:8 by centrifugal pump; In the extraction tank; the concentrated phospholipids and acetone are fully mixed by stirring in the tank, and the gear pump is fully refluxed until the phospholipids are suspended in the acetone solution and the small particles are completely dispersed, and the time is 40 minutes; start the centrifuge, and the phospholipid-acetone mixture is extracted from the The tank is pumped into the centrifuge for solid-liquid separation, the liquid phase enters the mixed oil storage tank, and the solid-phase phospholipids undergo secondary extraction; the secondary extraction time is 45 minutes; the secondary extracted mixed oil is pumped into the centrifuge for secondary separation After the centrifugation is comple...

Embodiment 2

[0028] Embodiment 2: With reference to accompanying drawing, preparation method comprises the following steps, the acetone in the acetone storage tank is pumped in the extraction mixing tank once by the ratio of concentrated phospholipid and acetone 1: 22 by centrifugal pump; In the extraction tank; the concentrated phospholipids and acetone are fully mixed by stirring in the tank, and the gear pump is fully refluxed until the phospholipids are suspended in the acetone solution and the small particles are completely dispersed, and the time is 80 minutes; start the centrifuge, and the phospholipid-acetone mixture is extracted The tank is pumped into the centrifuge for solid-liquid separation, the liquid phase enters the mixed oil storage tank, and the solid-phase phospholipids undergo secondary extraction; the secondary extraction time is 75 minutes; the secondary extracted mixed oil is pumped into the centrifuge for secondary separation After centrifugation, the phospholipids a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com