Feito synthetic oil processing line

A synthetic oil and process technology, which is applied in the petroleum industry, hydroprocessing process, and hydrocarbon oil treatment. It can solve the problems of easy solidification of heavy wax, serious equipment corrosion, and blockage of reactors, so as to improve product separation accuracy and product quality. Quality, reduce cooling load, improve the effect of heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

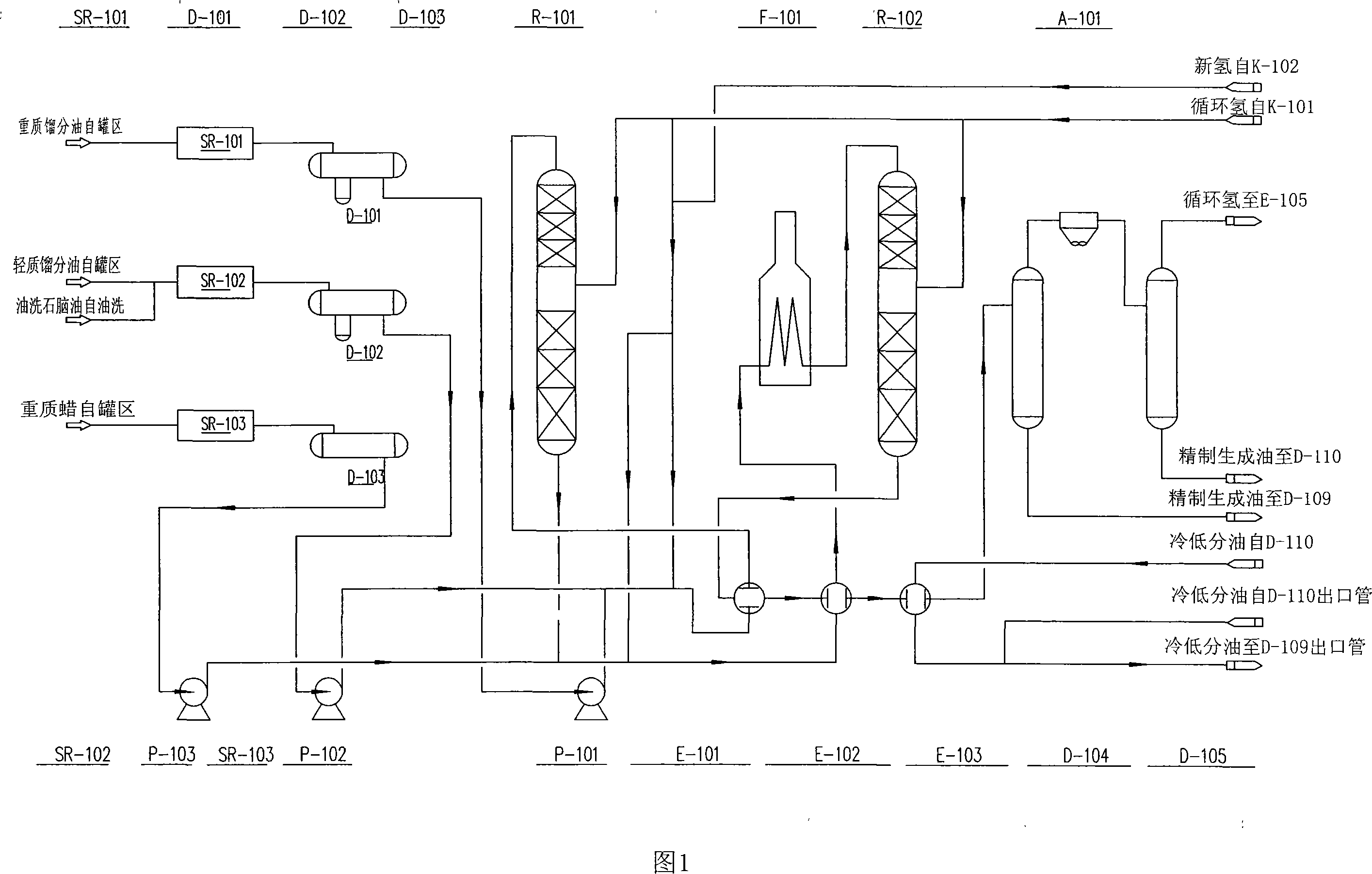

[0021] 1. Hydrogenation process

[0022] Light distillate oil and oil-washed naphtha from the border area are filtered through the light distillate oil filter (SR-102) and then enter the light distillate oil buffer tank (D-102); heavy wax from the border area passes through After being filtered by the heavy wax filter (SR-103), it enters the heavy wax buffer tank (D-103); the heavy distillate oil from the boundary area is filtered by the heavy distillate oil filter (SR-101), and then enters the heavy wax buffer tank (D-103); Quality distillate oil buffer tank (D-101), the buffer tank is sealed with nitrogen to prevent contact with air.

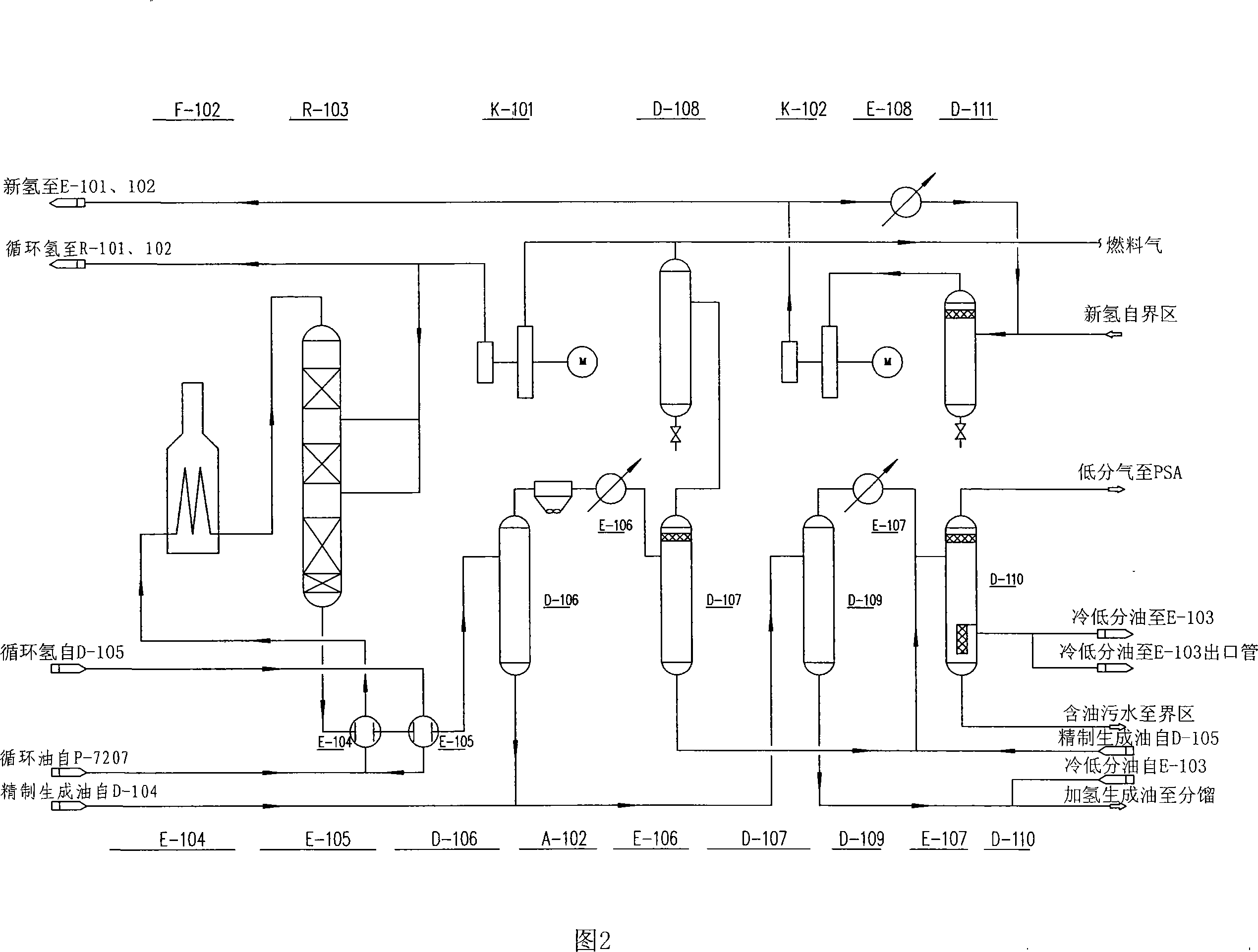

[0023] Light distillate oil, oil-washed naphtha and heavy distillate oil are respectively mixed after being pressurized by the light distillate oil feed pump (P-102) and heavy distillate oil feed pump (P-101). After mixing with the circulating hydrogen from the circulating hydrogen compressor (K-101) and the new hydrogen from the new hydrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com