A clutch lubrication structure and method

A lubricating structure and clutch technology, applied in the clutch field, can solve the problems of increasing cost, unable to achieve selective lubrication, reducing transmission efficiency, etc., to achieve the effect of convenient implementation, satisfying clutch lubrication requirements, and reducing drag loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

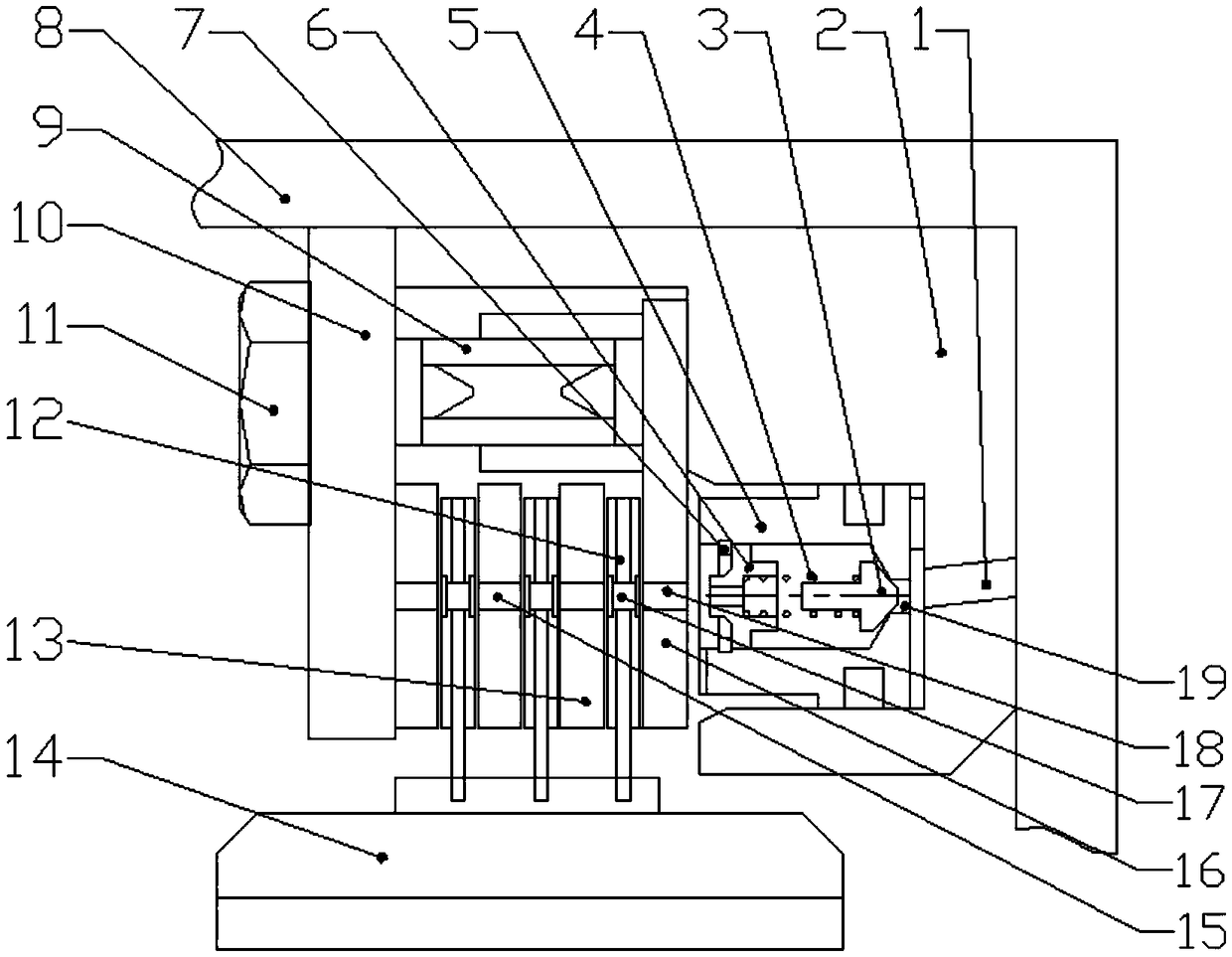

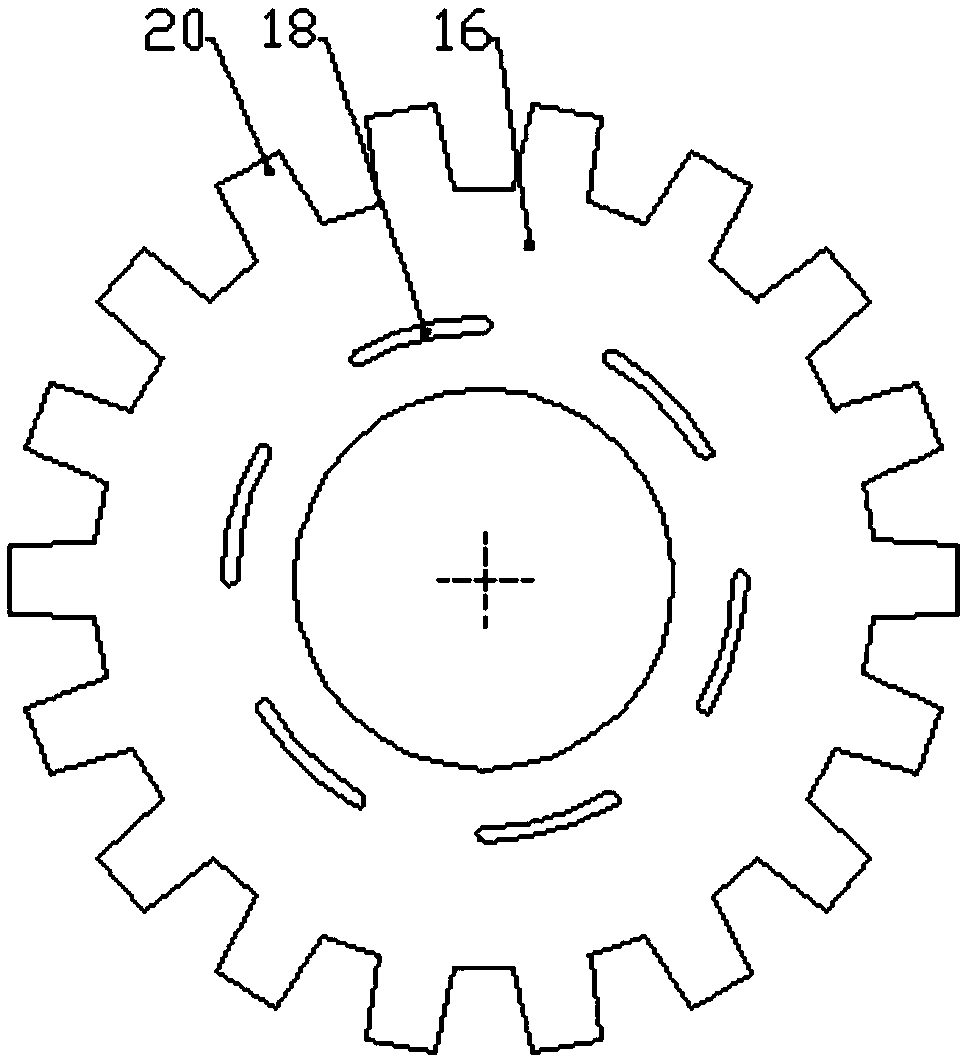

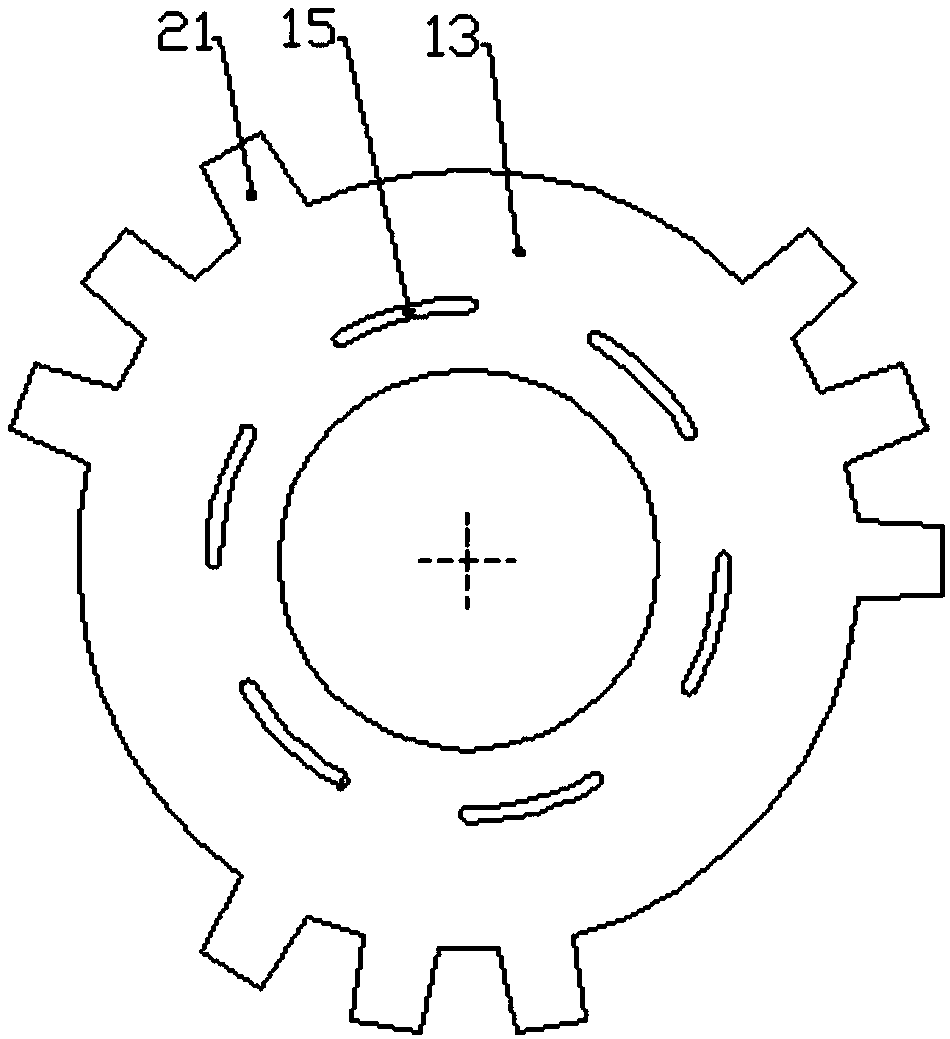

[0027] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0028] see Figure 1-Figure 6 , a clutch lubricating structure, including the back plate 10 and the piston housing 2 connected to the transmission housing 8 by bolts 11, and the first pair plates 13 are alternately arranged in the installation space formed by the back plate 10 and the piston housing 2 And the friction plate 12, the outer side of the friction plate 12 at the end is provided with a second dual plate 16, the first dual plate external teeth 21 of the first dual plate 13 and the second dual plate external teeth 20 of the second dual plate 16 are connected with the piston shell The internal teeth of the body 2 are mated and connected, and the diameter of the second dual plate 16 is greater than the diameter of the first dual plate 13 and the friction plate 12. A return spring 9 is arranged between the second dual plate 16 and the back plate 10, and the fric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com