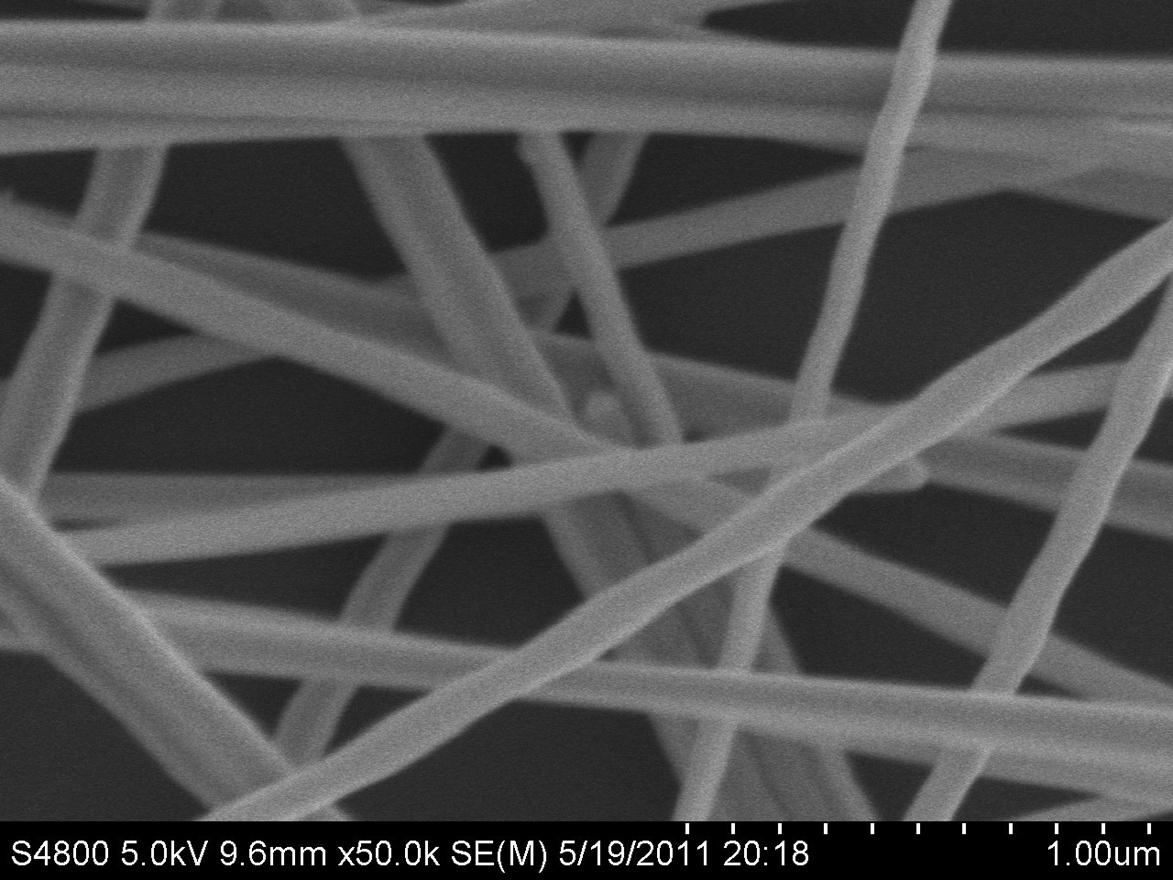

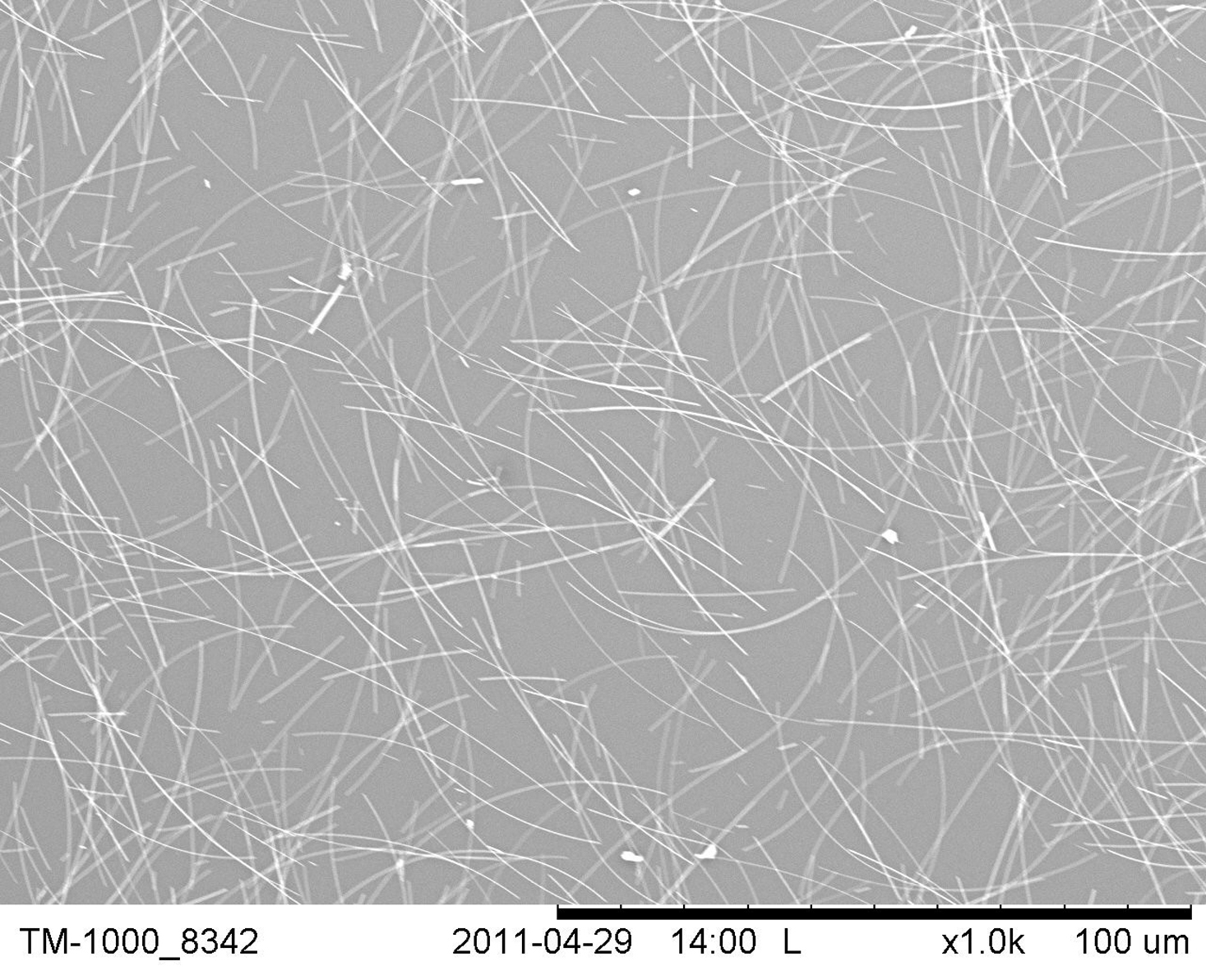

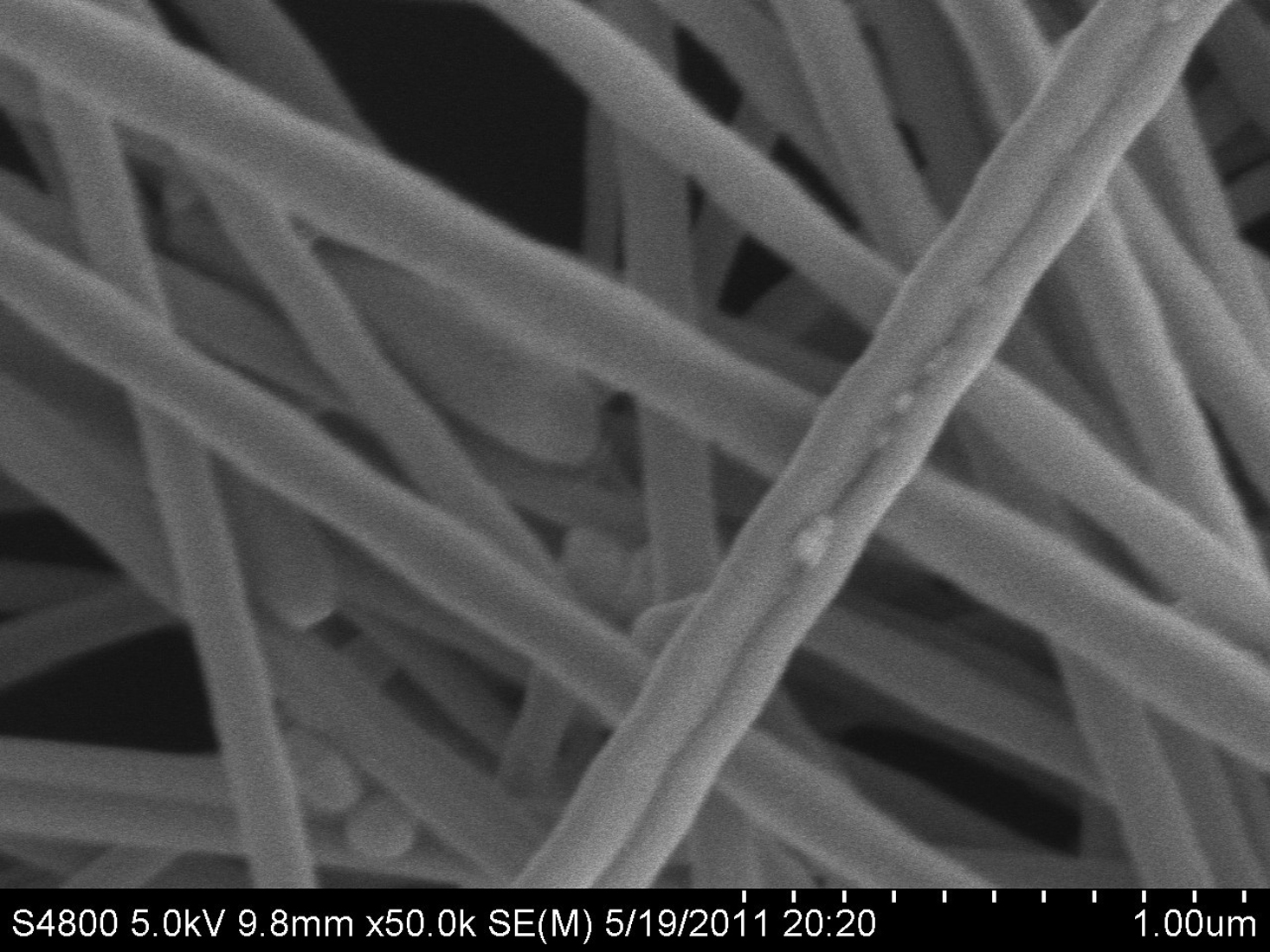

Method for preparing length-diameter-ratio nano-silver wire by pH-value regulation solvothermal method

A nano-silver wire and solvothermal technology, applied in the field of nano-silver wire material preparation, can solve the problems of high aspect ratio, non-uniformity, and many impurities, and achieve high aspect ratio, low cost, and good length uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Carry out according to preparation process: configure following solution:

[0043] A: concentration is the silver nitrate ethylene glycol solution of 0.2mol / L;

[0044] B: concentration is the ethylene glycol solution of polyvinylpyrrolidone whose K value is 30 of 0.4mol / L;

[0045] C: the concentration is: the ethylene glycol solution of the manganese chloride of 0.01mol / L;

[0046] D: concentrated nitric acid;

[0047] Take 1000 parts by volume of A, 1000 parts by volume of B, 25 parts by volume of C, and 1 part by volume of D solution and mix them thoroughly to form the final mixed solution. Move the mixed solution to the reaction kettle and place it at the preset temperature After reacting in an oven at 140°C for 2 hours, the reaction kettle was taken out and cooled to room temperature. To obtain the mother liquor of silver nanowires, add 1000 volumes of alcohol to the mother liquor to dilute and remove the upper clear night at a speed of 3000rpm to obtain a prec...

Embodiment 2

[0050] Carry out according to preparation process: configure following solution

[0051] A: concentration is the silver acetate glycol solution of 0.2mol / L;

[0052] B: the ethylene glycol solution of the polyvinylpyrrolidone whose K value is 90 that concentration is 0.4mol / L;

[0053] C: Concentration is: the ethylene glycol solution of ferric chloride of 0.01mol / L;

[0054] D: concentrated nitric acid;

[0055] Take 500 parts by volume of A, 800 parts by volume of B, 20 parts by volume of C, and 1 part by volume of D solution and mix them thoroughly to form the final mixed solution. Move the mixed solution to the reaction kettle and place it at the preset temperature After reacting in an oven at 160°C for 2 hours, the reaction kettle was taken out and cooled to room temperature. To obtain the mother liquor of silver nanowires, add 500 volumes of alcohol to the mother liquor to dilute and then remove the upper clear night at a speed of 3000rpm to obtain a precipitate, whic...

Embodiment 3

[0057] Carry out according to preparation process: configure following solution

[0058] A: concentration is the silver nitrate ethylene glycol solution of 0.2mol / L;

[0059] B: concentration is the ethylene glycol solution of polyvinylpyrrolidone whose K value is 30 of 0.4mol / L;

[0060] C: the concentration is: the ethylene glycol solution of the sodium chloride of 0.01mol / L;

[0061] D: concentrated hydrochloric acid;

[0062] Take 200 parts by volume of A, 250 parts by volume of B, 20 parts by volume of C, and 1 part by volume of D solution and mix them thoroughly to form the final mixed solution. Move the mixed solution to the reaction kettle and place it at the preset temperature After reacting in an oven at 130°C for 2.5 hours, the reaction kettle was taken out and cooled to room temperature. To obtain the mother liquor of silver nanowires, add 1000 volumes of alcohol to the mother liquor to dilute and then remove the upper clear night at a speed of 1500rpm to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com