Preparation method for bismuth-tellurium nano-porous thermoelectric material

A nanoporous, thermoelectric material technology, applied in the manufacture/processing of thermoelectric devices, can solve the problems of low sintering temperature, long time, short time, etc., and achieve the effect of accurate composition control, uniform size and distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

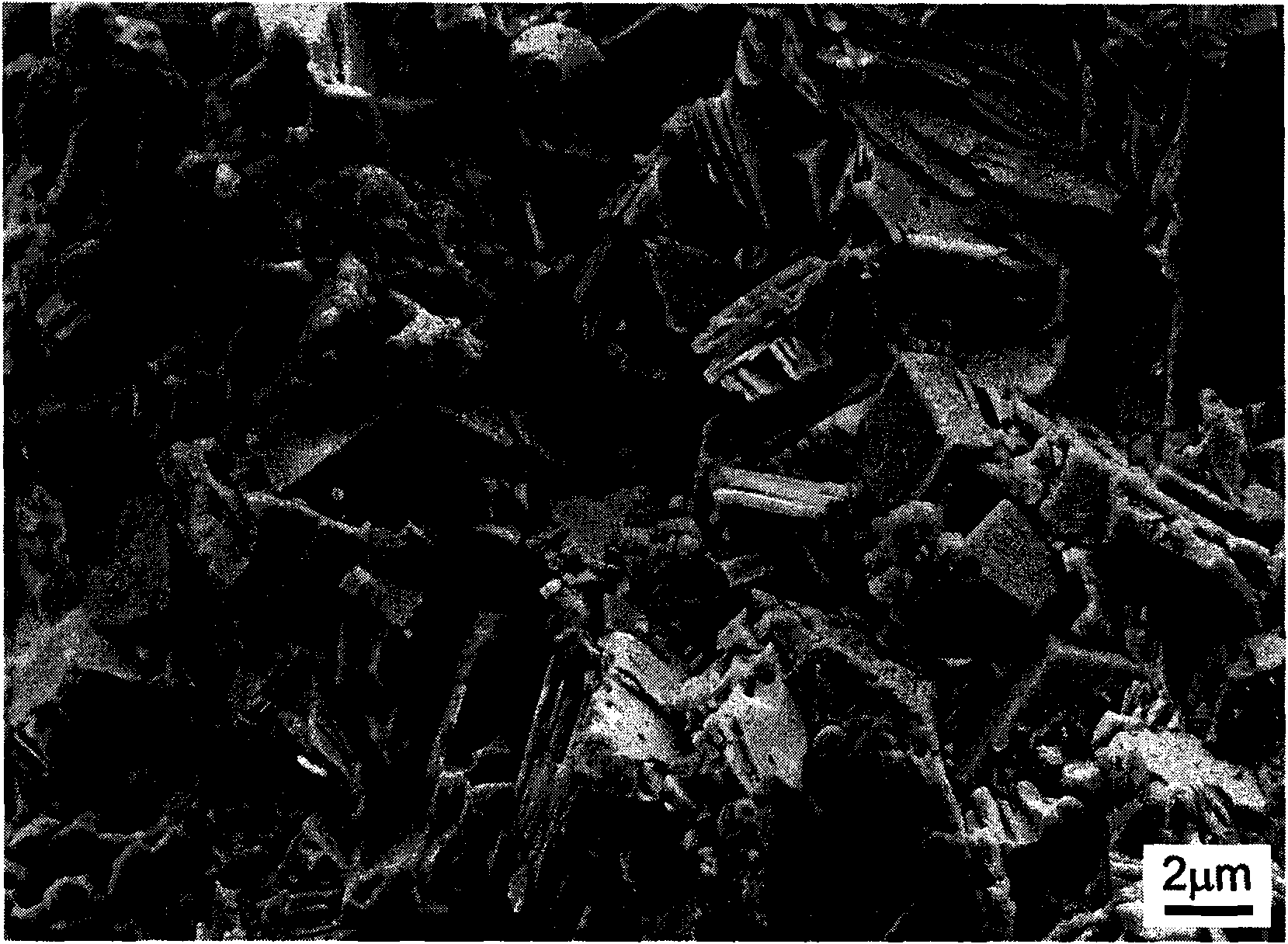

Image

Examples

Embodiment 1

[0022] According to the stoichiometric ratio Bi 2-x Sb x Te 3-y Se y (x=0-1.9, y=0-0.5) will analyze pure Bi(NO 3 ) 3 , SbCl 3 Te powder and Se powder with a purity of 99.999% and a particle size of 500 mesh were weighed and mixed into organic solvents or deionized water, and the corresponding reducing agent (sodium hypophosphite, hydrazine hydrate or sodium borohydride) was added to configure the Pour the mixed solution of PTFE into a reaction kettle lined with polytetrafluoroethylene, stir for about 10-15 minutes, then fill it with deionized water to a filling degree of 80%-90%, seal the reaction kettle and heat it to 150-180°C, After 24-48 hours of heat preservation, cool down to room temperature naturally, collect the black or dark gray powder reaction product at the bottom of the kettle, wash it repeatedly with deionized water, alcohol and acetone, and dry the obtained gray-black powder at 60-70°C for 6- 10h.

[0023] (1) The hydrothermal synthesis stoichiometric r...

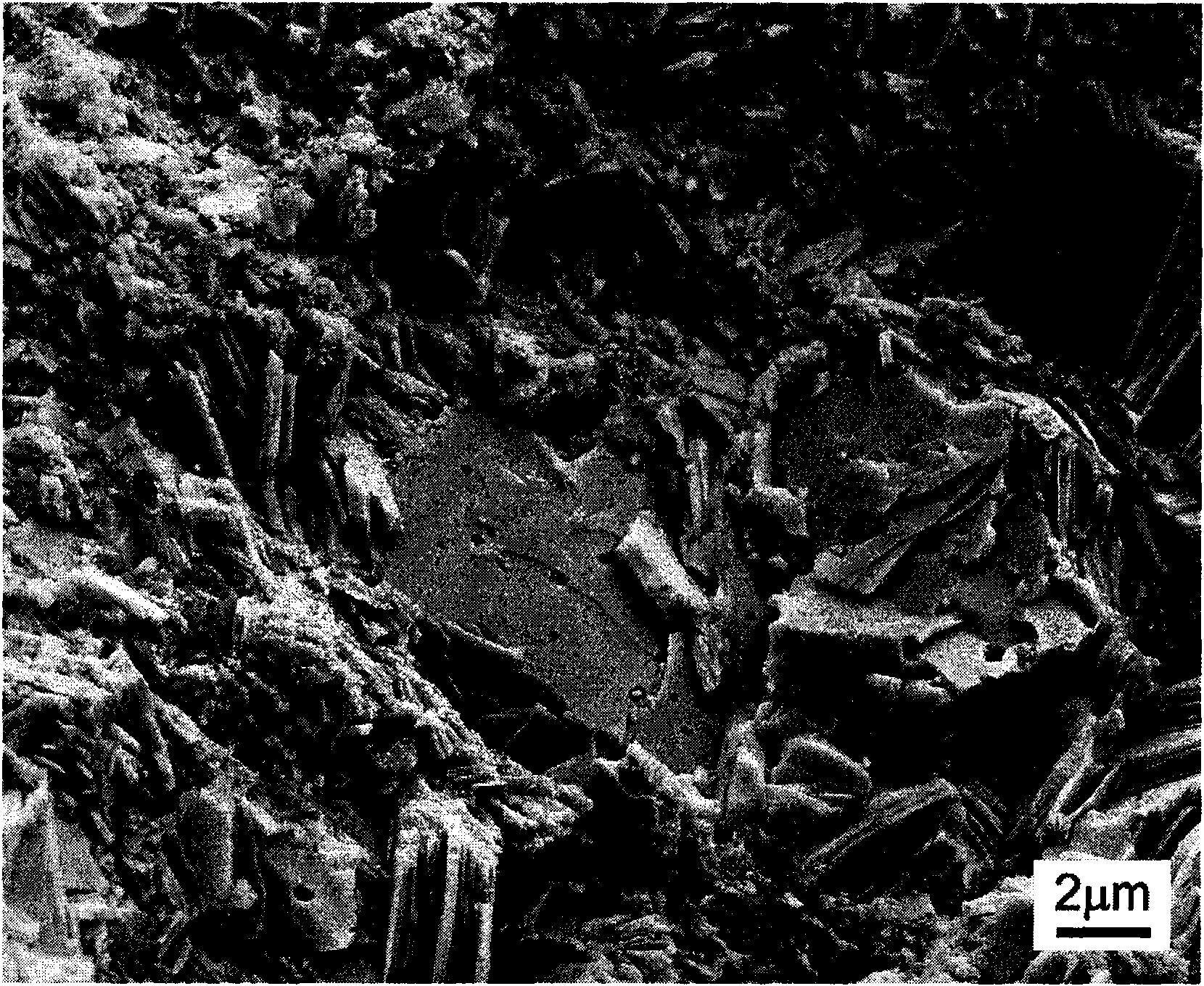

Embodiment 2

[0029] (1) According to the stoichiometric ratio Bi 2-x Sb x Te3-ySe y(x=1.9, y=0.5) The P-type bismuth-tellurium-based nano-powder synthesized by hydrothermal method is placed in the alcohol solution dissolved with 10wt% pore-forming agent isophthalic acid according to the proportion, and an appropriate amount of P-type dopant is added Te (3.5wt%), after stirring with a glass rod for 15 minutes, put it into an ultrasonic cleaner for 45 minutes, then add a Teflon magnetic stirrer to the solution, and stir for 30 minutes through a magnetic suspension stirrer;

[0030] (2) Repeat step (1) twice to make the powder evenly dispersed in the solution, during which part of the alcohol in the solution has volatilized;

[0031] (3) Dry the uniformly mixed powder in a constant temperature drying oven, keep the drying temperature at 60°C, and keep warm until the powder is completely dry;

[0032] (4) Collect the dried powder and perform spark plasma sintering. The SPS sintering temper...

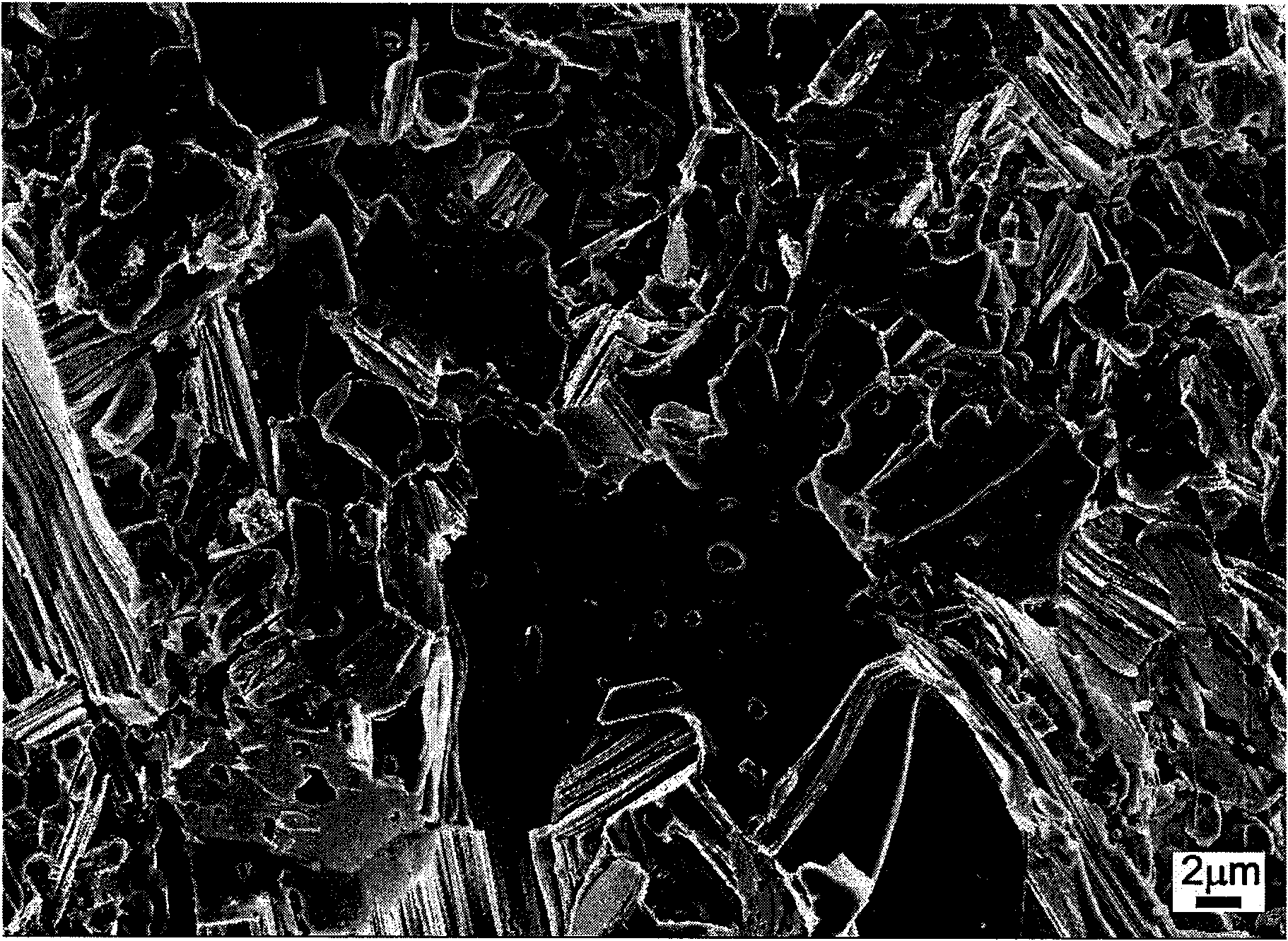

Embodiment 3

[0035] Synthesis of N-type and P-type bismuth-tellurium-based nanopowders by vacuum melting: According to the stoichiometric ratio Bi 2-x Sb x Te 3-y Se y (x=0-1.9, y=0-0.5) Weigh metal Bi, Sb, Te and Se and n or p-type dopant with a purity of more than 99.999% and vacuum seal them in a high boron glass tube. Place the tube in a muffle furnace and heat it up to 600-750°C at a rate of 5-7°C / min for 1-3 hours, during which the glass tube is shaken every 20-25 minutes to ensure that the metals and dopants are prepared A uniform chemical reaction occurs between them and the desired compound is generated, and then the glass tube is taken out of the muffle furnace and placed in an ice-cold container to cool quickly to obtain nanocrystalline Bi 2-x Sb x Te 3-y Se y (x=0-1.9, y=0-0.5). Then, the synthesized material was crushed to 100-200 meshes in a vibration crusher under the protection of Ar gas.

[0036] (1) According to the stoichiometric ratio Bi 2-x Sb x Te 3-y Se y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com