Preparation method of nanometer composite film ammonia gas sensor

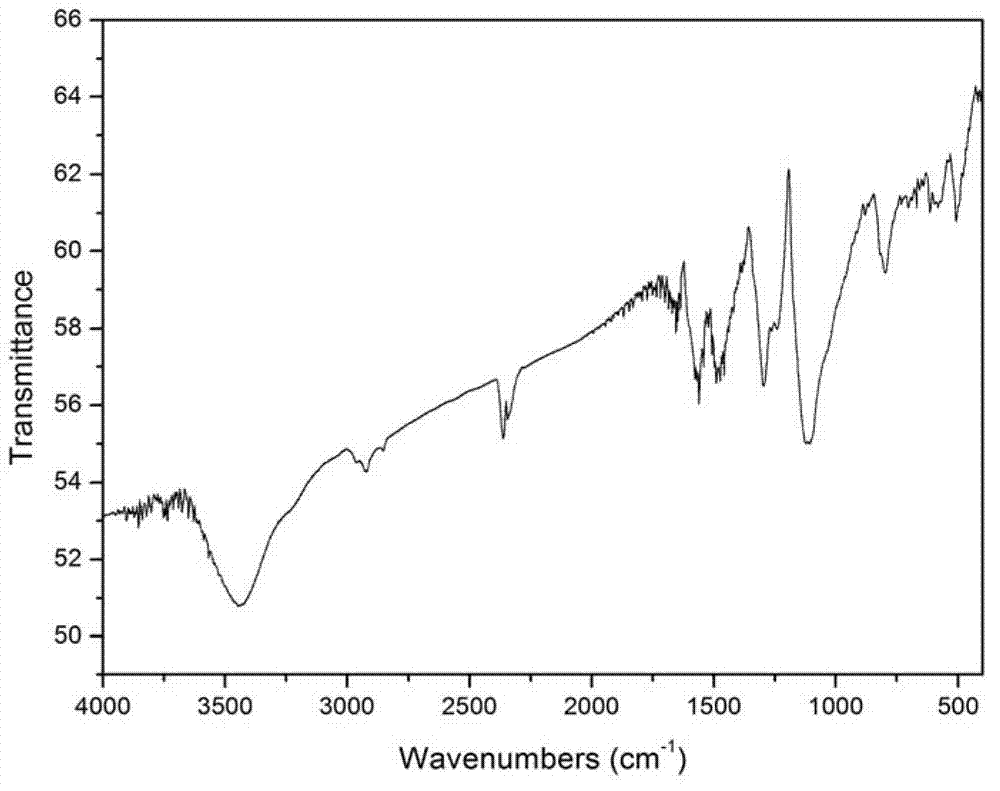

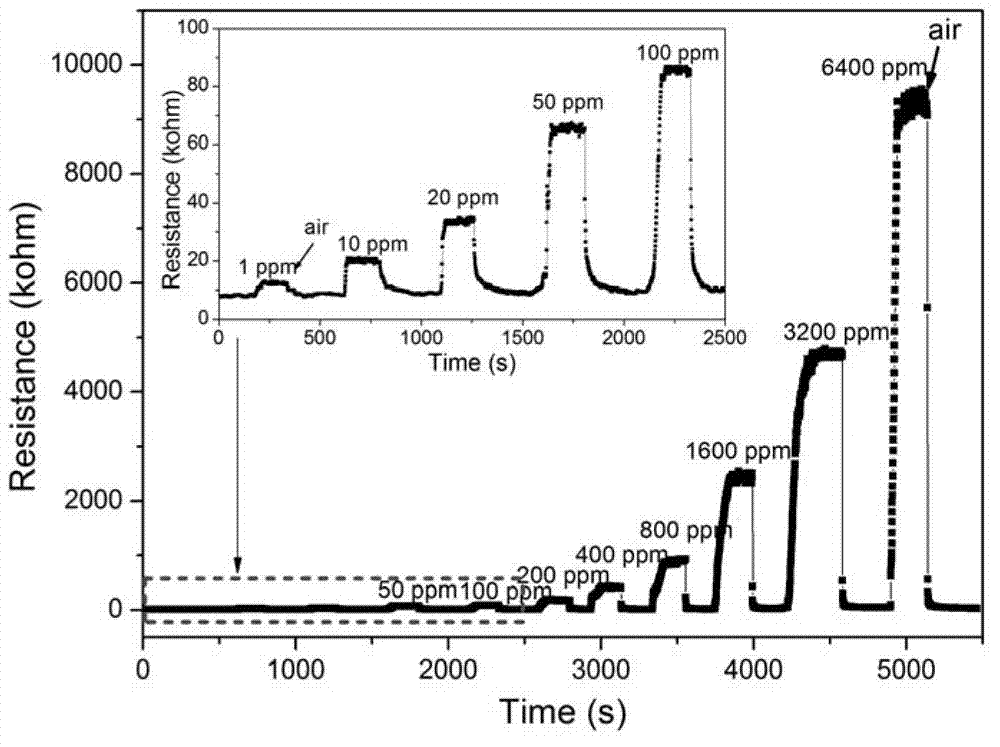

An ammonia gas sensor and nanocomposite technology, applied in the direction of material resistance, can solve the problems of poor ammonia gas selectivity, poor stability of sensitive membrane, low sensitivity, etc., and achieve low recovery time, good detection sensitivity, and response-recovery characteristics. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

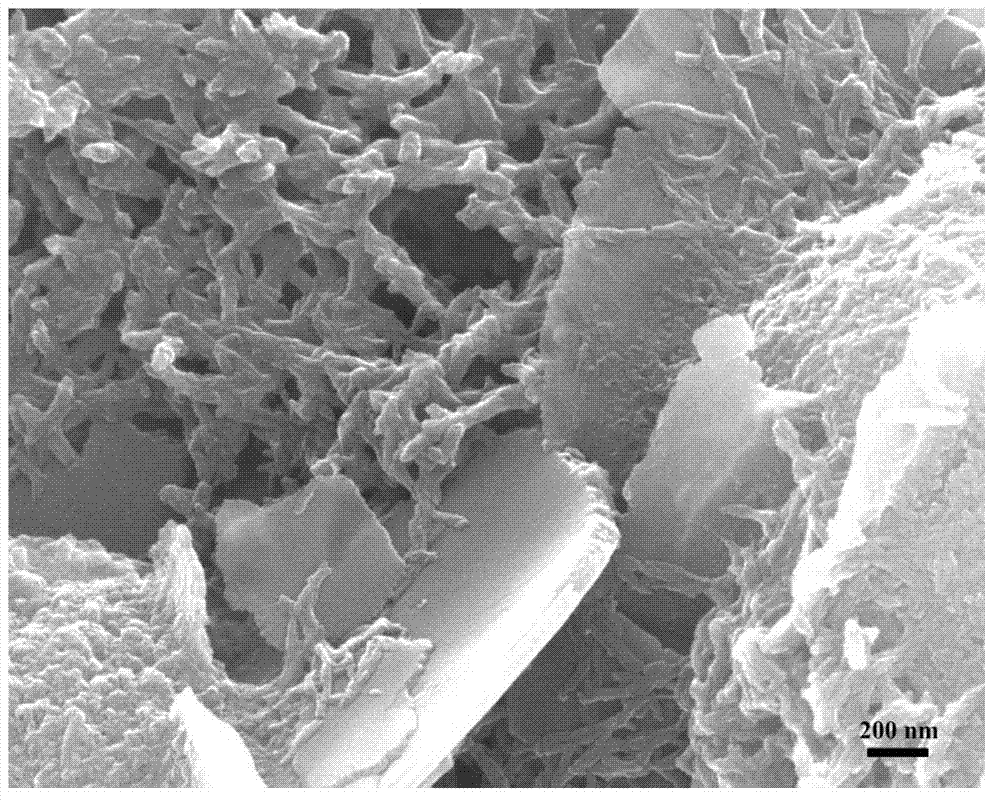

[0021] A preparation method of a nanocomposite film ammonia sensor, the steps are as follows:

[0022] 1) Take 18.6 parts by weight of aniline monomer, disperse it into deionized water, add 0.3 parts by weight of graphene sheet, stir and mix until uniform;

[0023] 2) in the mixed liquor that 1) step obtains, add the hydrochloric acid solution of 900 parts of weight 1 mol / liter, be placed in ice-water bath and continue to stir for 30 minutes; Add the ammonium persulfate solution containing the ammonium persulfate of 456 parts weight immediately, Continue stirring reaction in ice-water bath for 15 hours;

[0024] 3) Take the precipitate by filtration, wash it with deionized water and alcohol, and dry it for 24 hours to obtain a dry powder; then disperse the powder in an alcohol solution with a concentration of 30% (v / v), and obtain a uniform dispersion after ultrasonication for 3 hours liquid;

[0025] 4) Coat the dispersion liquid obtained in step 3) on the interdigital elec...

Embodiment 2

[0030] A preparation method of a nanocomposite film ammonia sensor, the steps are as follows:

[0031] 1) Take 18 parts by weight of aniline monomer, disperse it in deionized water, then add 0.1 part by weight of graphene, stir and mix until uniform;

[0032] 2) add 700 parts of heavy 1 mol / liter hydrochloric acid solution in the mixed liquor that 1) step obtains, place in ice-water bath and continue to stir for 20 minutes; Then add the ammonium persulfate solution containing 456 parts of heavy ammonium persulfate, Placed in an ice-water bath and continued stirring for 14 hours;

[0033] 3) Take the precipitate by filtration, wash it with deionized water and alcohol, and dry it for 30 hours to obtain a dry powder; then disperse the powder in an alcohol solution with a concentration of 15% (v / v), and obtain a uniform dispersion after ultrasonication for 4 hours liquid;

[0034] 4) Coat the dispersion liquid obtained in step 3) on the interdigital electrodes; after the alcohol...

Embodiment 3

[0036] A preparation method of a nanocomposite film ammonia sensor, the steps are as follows:

[0037] 1) Take 20 parts by weight of aniline monomer, disperse it in deionized water, add 3 parts by weight of graphene, stir and mix until uniform;

[0038] 2) in the mixed liquor that 1) step obtains, add the hydrochloric acid solution of 1000 parts of weight 1 mol / liter, be placed in ice-water bath and continue to stir 40 minutes; Add the ammonium persulfate solution containing the ammonium persulfate of 456 parts of weight immediately, Placed in an ice-water bath and continued stirring for 18 hours;

[0039] 3) Take the precipitate by filtration, wash it with deionized water and alcohol, and dry it for 72 hours to obtain a dry powder; then disperse the powder in an alcohol solution with a concentration of 40% (v / v), and obtain a uniform dispersion after ultrasonication for 5 hours liquid;

[0040] 4) Coat the dispersion liquid obtained in step 3) on the interdigital electrodes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com