Multi-element high-entropy alloy film and preparation method thereof

An alloy thin film, multi-element high-entropy technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problem that it is difficult to obtain single-phase solid solution high-entropy alloys, hinder the wide application of high-entropy alloys, and the preparation process. Complexity and other problems, to achieve the effect of stable sputtering rate, promotion of formation, and simple and easy operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of a kind of multivariate high-entropy alloy film of the present invention is as follows:

[0033] 1) First, ultrasonically clean the silicon wafer substrate polished on one side in acetone, and then conduct ultrasonic cleaning with alcohol and deionized water in sequence;

[0034] 2) Then put the washed silicon substrate on the filter paper to dry, with the polished side facing up;

[0035] 3) Put the dried silicon wafer substrate and the high-entropy alloy bulk target into the sample stage and the evaporation source position in the vacuum chamber of the DC magnetron sputtering equipment, respectively;

[0036] 4) Close the vacuum chamber of the DC magnetron sputtering equipment, and evacuate the air pressure to less than 4×10 -4 Pa, rush into the argon with a volume percentage greater than or equal to 98% as the working gas;

[0037] 5) Under the working pressure of 0.3-1Pa, while the sample stage valve and the evaporation source valve are clo...

Embodiment 1

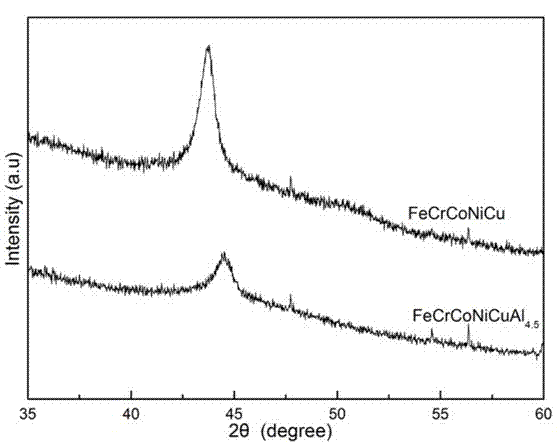

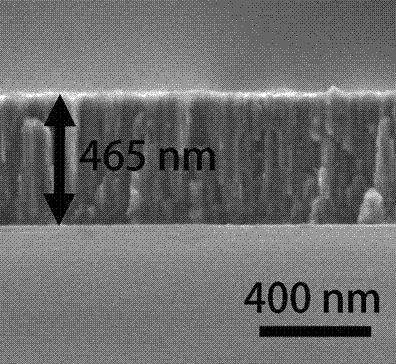

[0048] This embodiment adopts the method of DC magnetron sputtering mentioned in the present invention, has successfully prepared NiCrCoCuFe (the molar ratio of each element is Ni:Cr:Co:Cu:Fe=1:1:1:1:1 ) five-element high-entropy alloy thin film material. The thickness of the high-entropy alloy thin film material is uniform, and only a simple FCC solid solution phase is found in the thin film material, and the existence of the second phase is not found.

[0049] The preparation method of this high-entropy alloy thin film material, its steps are as follows:

[0050]1) First, put the single-side polished silicon wafer substrate in acetone for 10 minutes for ultrasonic cleaning with an ultrasonic power of 80w, and then perform ultrasonic cleaning with alcohol and deionized water in sequence. The cleaning time is 10 minutes, and the ultrasonic power is 80w;

[0051] 2) Then place the washed silicon wafer substrate on filter paper to dry, with the polished side facing up, and blow...

Embodiment 2

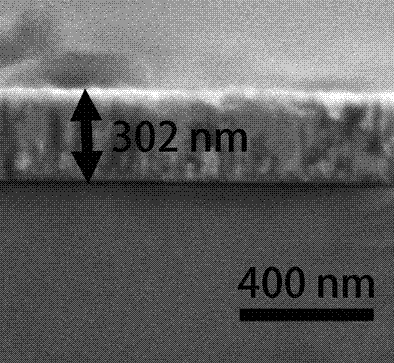

[0058] This embodiment adopts the method of DC magnetron sputtering mentioned in the present invention, has successfully prepared NiCrCoCuFe (the molar ratio of each element is Ni:Cr:Co:Cu:Fe=1:1:1:1:1 ) five-element high-entropy alloy thin film material. The thickness of the high-entropy alloy thin film material is uniform, and only a simple FCC solid solution phase is found in the thin film material, and the existence of the second phase is not found.

[0059] The preparation method of this high-entropy alloy thin film material, its steps are as follows:

[0060] 1) First, put the single-side polished silicon wafer substrate in acetone for 15 minutes for ultrasonic cleaning, with an ultrasonic power of 90w, and then perform ultrasonic cleaning with alcohol and deionized water in sequence. The cleaning time is 15 minutes, and the ultrasonic power is 90w;

[0061] 2) Then place the washed silicon wafer substrate on filter paper to dry, with the polished side facing up, and bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com