Covered carbide plug and cold drawing method using the covered carbide plug

A kind of coating, superhard technology, applied in the direction of coating, superimposed layer plating, metal material coating process, etc., can solve the problems of reduced service life of the plug, scratches, TiCN film peeling, etc., and achieves a long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

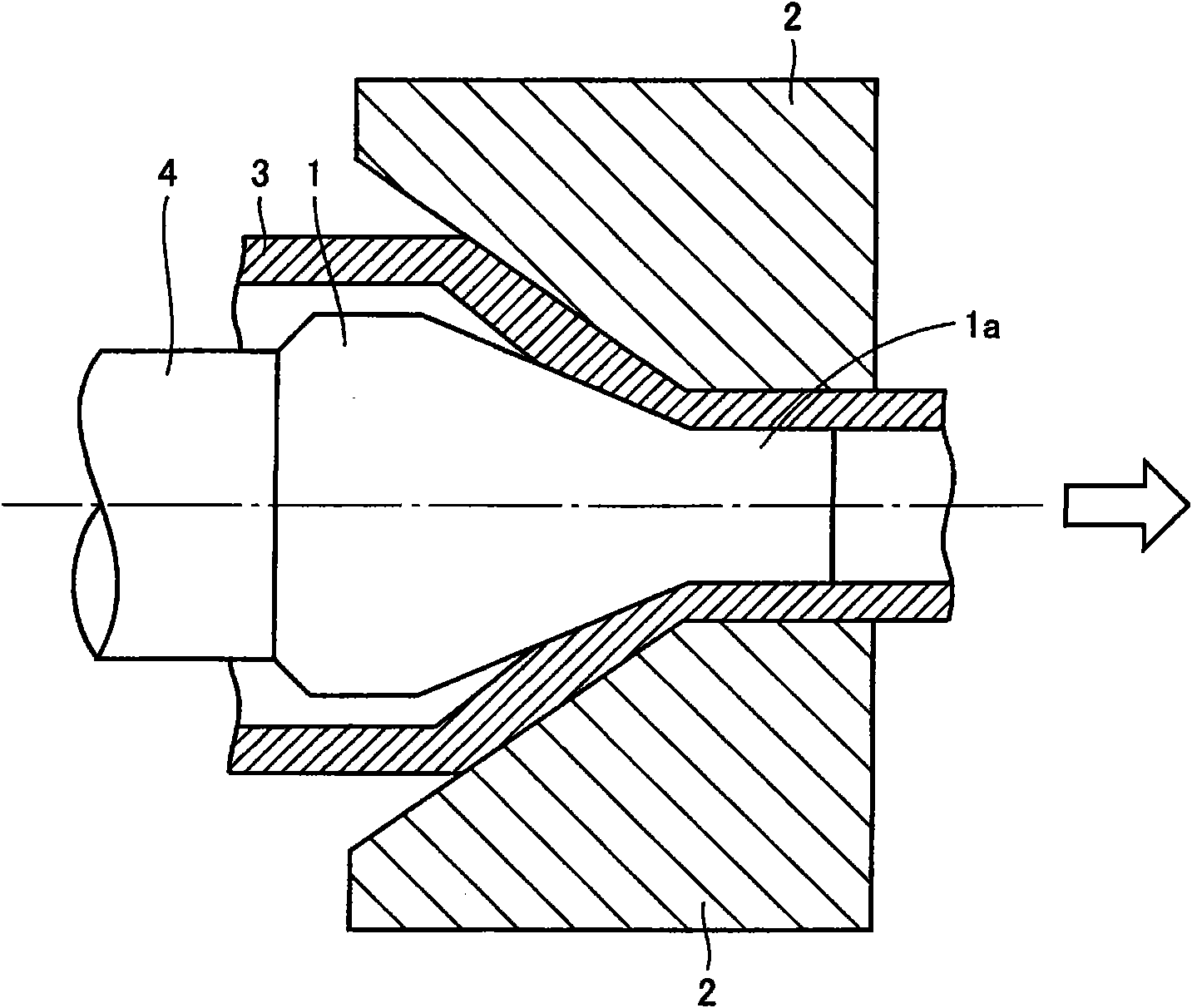

[0044] As the steel pipe for the test of Example 1, the steel type is JIS STBA26 (9Cr-1Mo steel), and the pipe which was finish-rolled by the Manesmann mandrel rolling method was prepared. In order to carry out the tube softening treatment on the received tube blank, the tube blank was subjected to a heat treatment at 800°C for 10 minutes in a roller hearth furnace, and then the tube blank was removed by pickling treatment on the inner and outer surfaces of the tube blank. Scale, after which lubrication treatment was implemented.

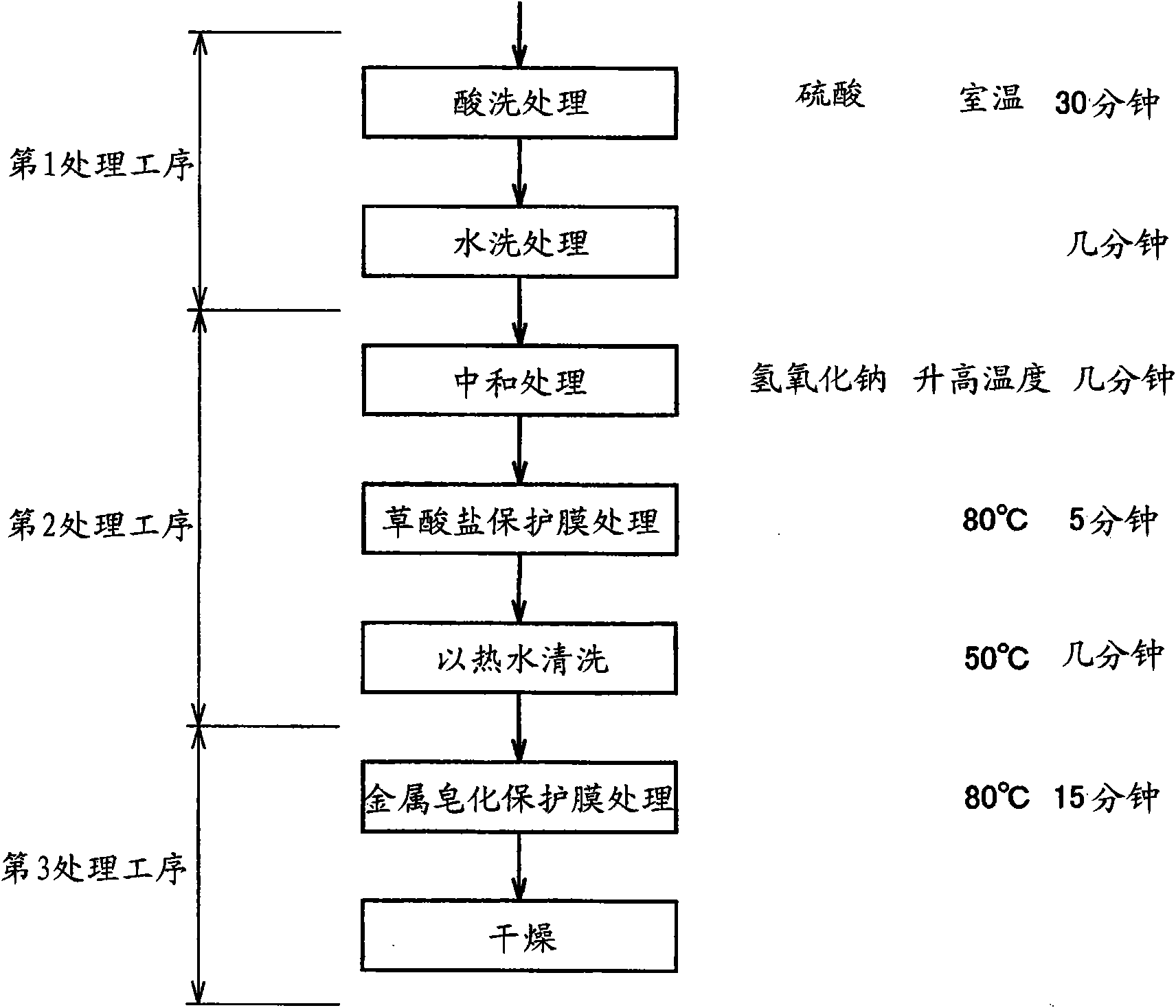

[0045] As a specific chemical conversion treatment before the drawing process, use sulfuric acid (10-13%) to carry out pickling treatment at room temperature and for 30 minutes, then perform water washing treatment, neutralization treatment, and then perform treatment at a temperature of The state of 75-85 °C, the treatment time is 5 minutes of oxalate protective film treatment, the sodium stearate is reacted with the oxalate protective film under t...

Embodiment 2

[0053] As a steel pipe for a test in Example 2, a steel grade corresponding to JISSUS 304 stainless steel and a pipe finish-rolled by the Manesmann mandrel rolling method were prepared. The received tube blanks were heat treated at 1230° C. for 2 minutes in a roller hearth furnace, then lubricated by chemical conversion treatment after descaling by pickling treatment.

[0054] As the drawing process, the size of the tube blank is set to an outer diameter of 54.0 mm x wall thickness of 7.9 mm, and the drawing size is set to an outer diameter of 44.50 mm x wall thickness of 6.30 mm, and the reduction rate of the section shown in the above formula (1) is Rd is set at 33.9%.

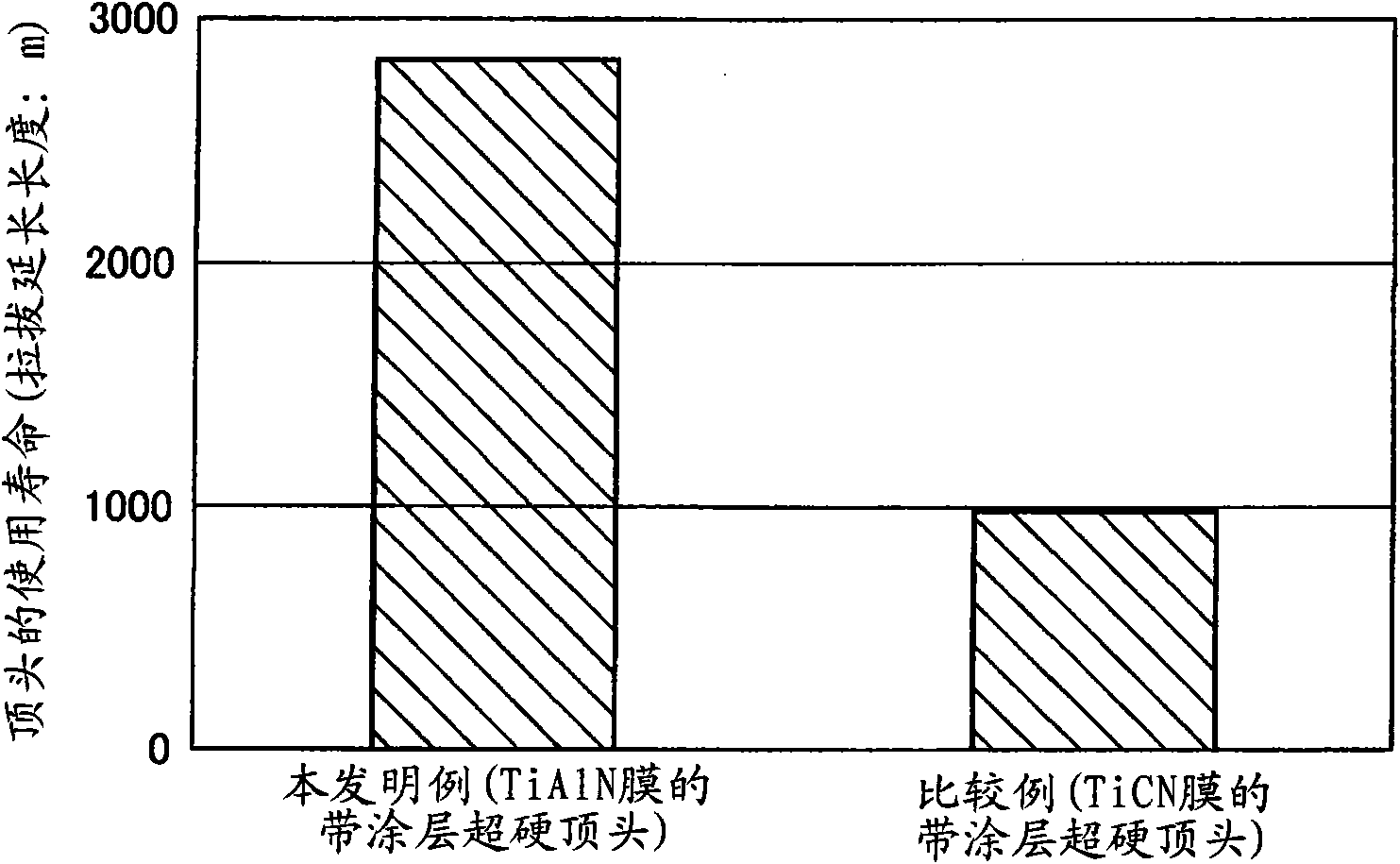

[0055] Identical to embodiment 1, use superhard mold as mould, the band coating superhard plug (comparative example) of the band coating superhard plug (comparative example) of the band coating superhard plug (comparative example) that is divided into TiAlN film and TiCN film for drawing with the plug divisi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com