Forming Tool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

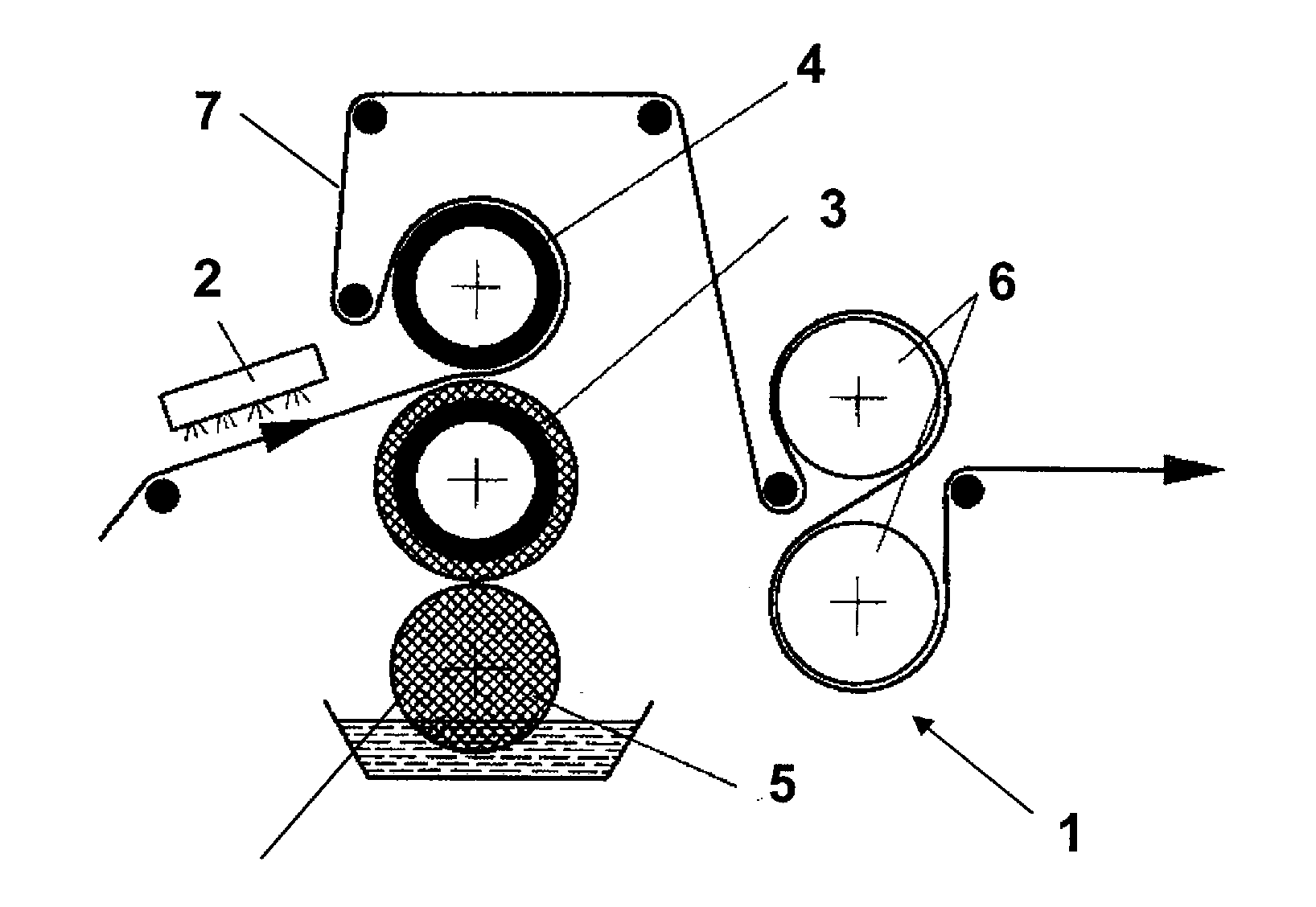

[0066]In FIG. 1 the embossing calender 1 contains an infrared heater 2 to soften the continuous sheet material 7 or at least its surface. The sheet material 7 can be a plastic sheet, or a sheet made of one or more materials other than plastic, coated with a plastic material, in particularly a thermoplastic material. Sheet material can comprise e.g. a metal, reinforcing fibres or fibre fabrics. The softened or melted plastic surface of the sheet material is then embossed by means of a chilled embossing roll 4 coated with metallic glass, which interacts with a second roll 3 producing a counter-pressure to the sheet material 7 passing the roll gap. The calender unit 1 further comprises a cooling roll 5 to cool the counter-pressure roll 3 and cooling rolls 6 to cool the sheet material.

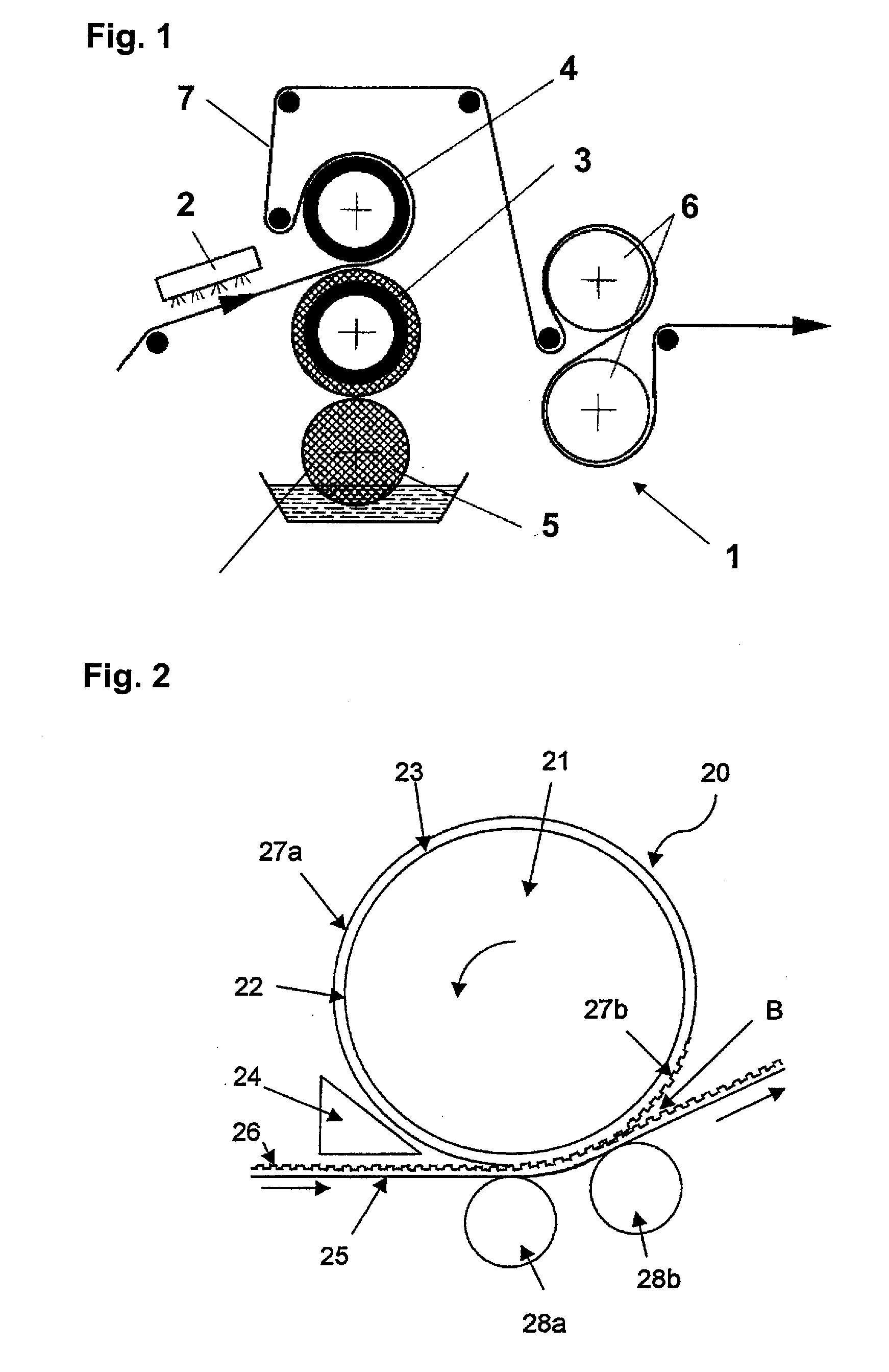

[0067]In FIG. 2 the forming tool 20 is in the form of a cylindrical work roll of a polymer processing unit as e.g. described under FIG. 1. The forming tool 20 comprises a cylindrical substrate 21 and a met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com