Forming tools

A technology of forming tools and tools, applied in the direction of manufacturing tools, cutting tools, metal drawing forming tools, etc., can solve the problems of strong adaptability and the inability to provide forming tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

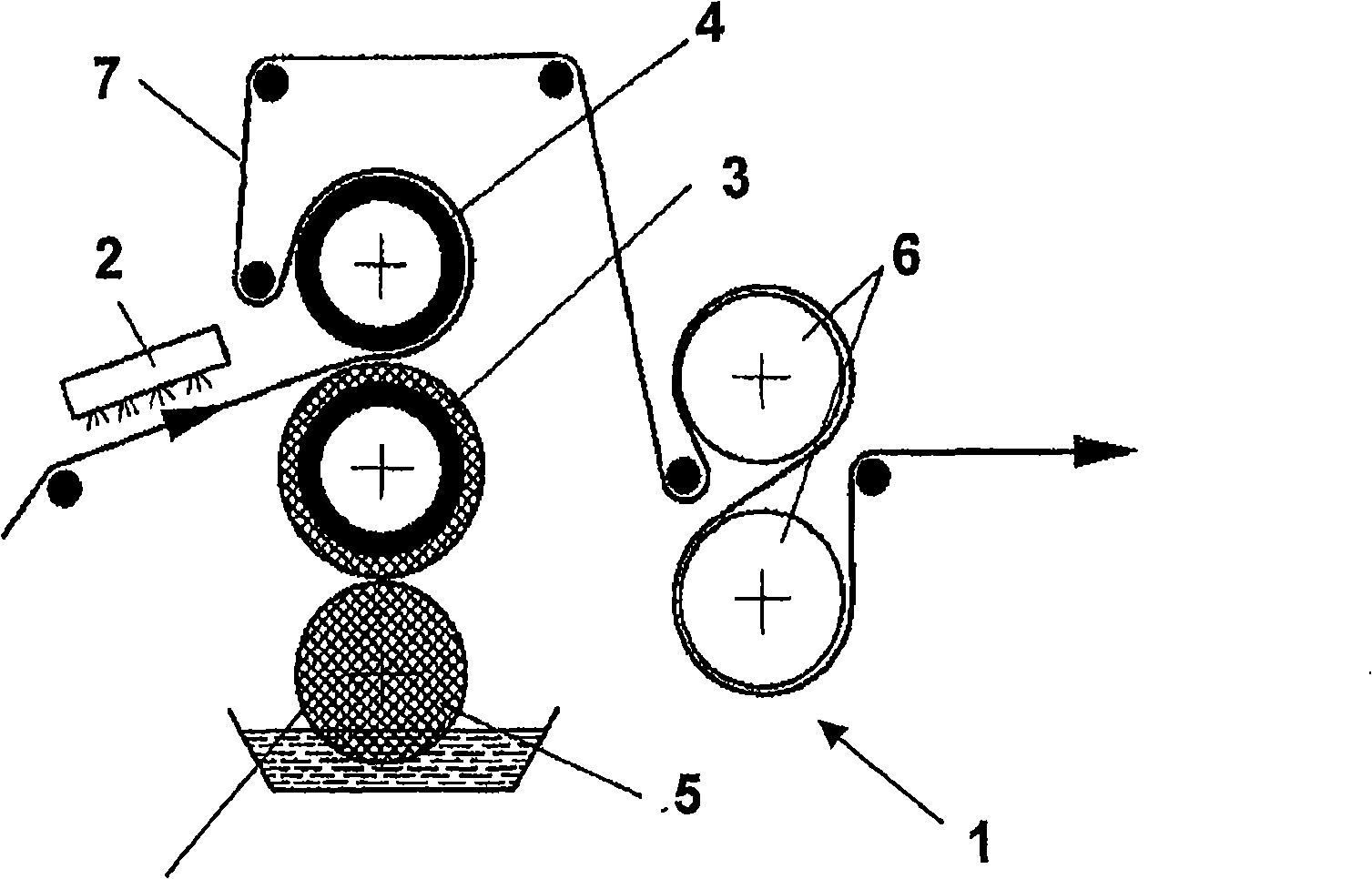

[0067] exist figure 1 In , the calender 1 for embossing comprises an infrared heater 2 which softens the continuous sheet material 7, or at least softens its surface. The sheet material 7 may be a plastic sheet, or a sheet made of one or more materials other than plastic, coated with a plastic. Sheet materials may include, for example, metal, reinforced fibers, or fabrics. The softened or molten plastic surface of the sheet material is then embossed by means of tempered embossing rollers coated with metallic glass. The embossing roll interacts with the second roll 3, creating an opposing pressure 7 on the sheet material passing through the nip. The calendering unit 1 also includes a cooling roll 5 which cools the counter pressure roll 3 and a cooling roll 6 which cools the sheet material.

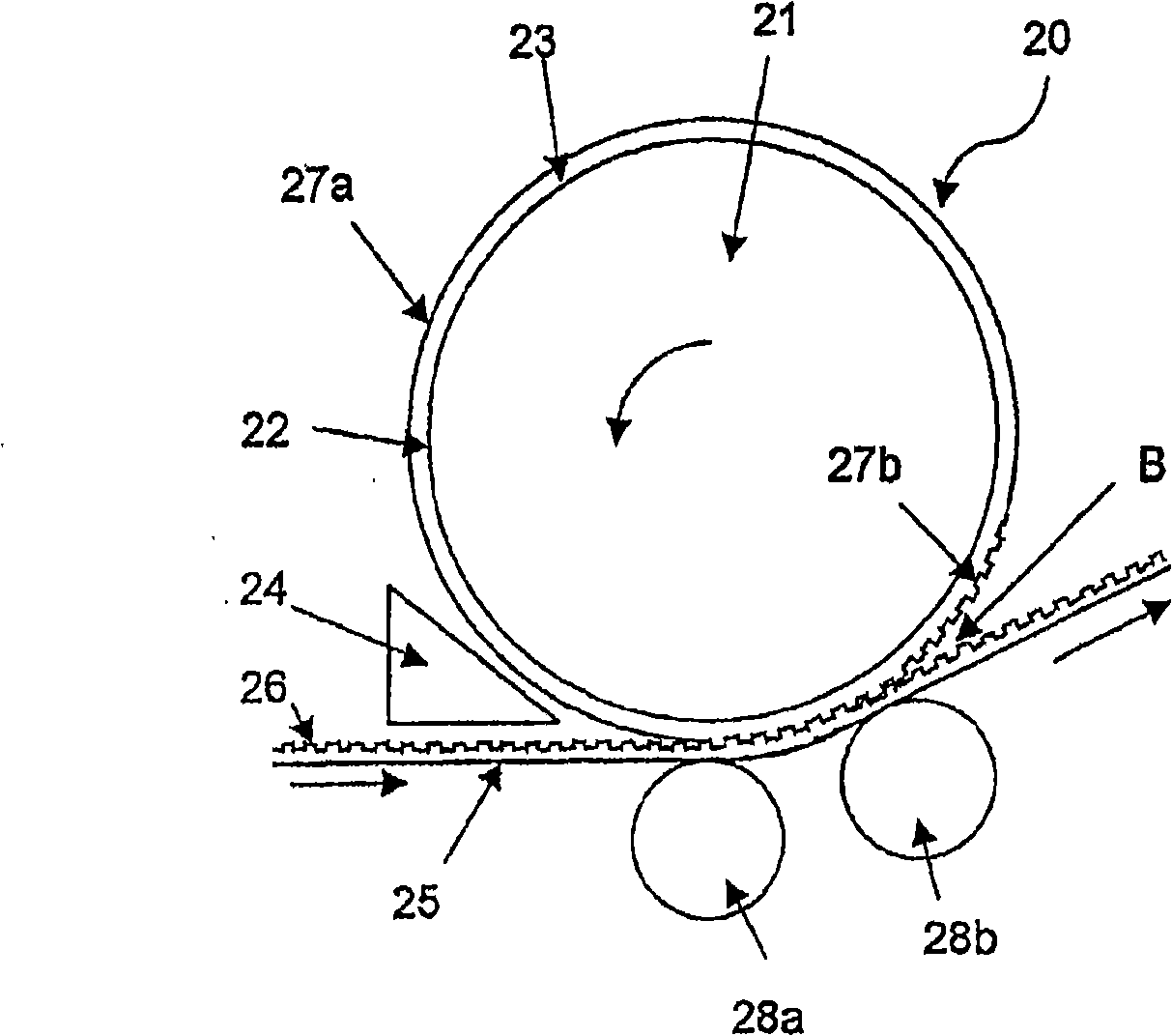

[0068] exist figure 2 , the forming tool 20 is in the form of a cylindrical work roll of a polymer processing unit, as for example in figure 1 as described in. The forming tool 20 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com