Preparation method of aluminum capillary tube of refrigerating system

A refrigeration system and capillary technology, applied in the direction of the mandrel, etc., can solve the problems that the aluminum capillary cannot be realized, and the drawing method of the aluminum tube cannot be realized, so as to achieve the effects of low manufacturing cost, weight reduction and consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

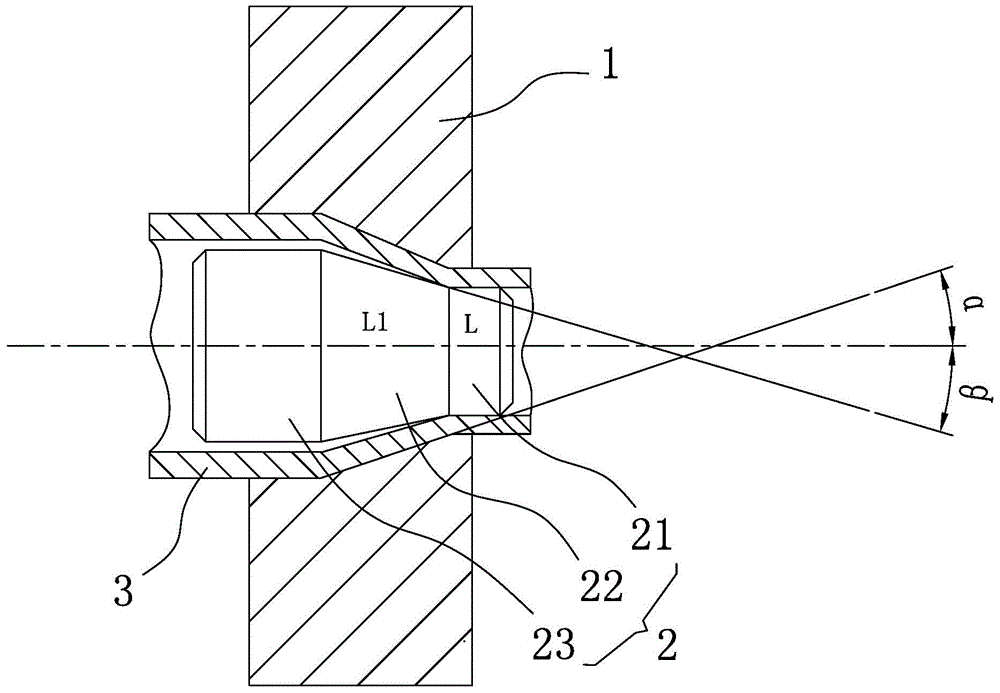

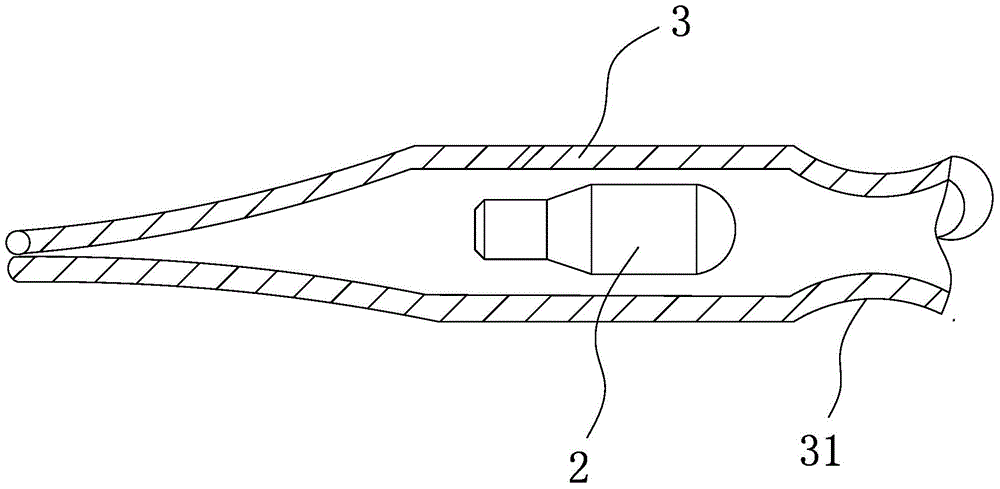

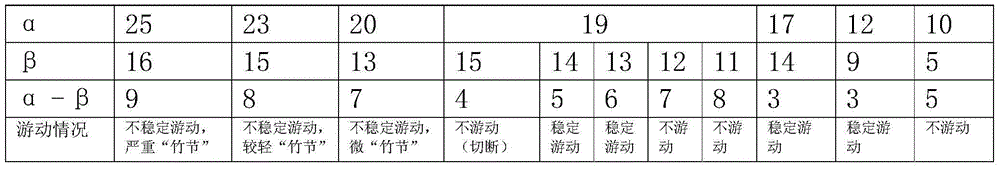

[0026] Example: see figure 1 and figure 2 , a method for preparing an aluminum capillary tube in a refrigeration system. The aluminum blank tube 3 is drawn by cold drawing technology, and a drawing die is used during drawing. The die includes an outer mold 1 and a matching mold core 2, wherein the mold core There is a sizing portion 21 of the core head, the drawing force of the aluminum billet tube increases with the increase of the length of the sizing portion of the core head, and the moving mold core pulls the billet tube in a disk to form an aluminum capillary tube of the refrigeration system. The mold core 2 of the present invention also has an intermediate conical portion 22 and a core tail cylindrical portion 23, and the length of the sizing portion of the core head is determined by the following formula: The unit is mm; among them, D is the diameter of the core end cylinder, in mm, d is the diameter of the cylinder at the fixed part of the core head, in mm, f is the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com