Core rod cycle device for drawing and extending hydraulic machine

A circulation device and mandrel technology, applied in the direction of the mandrel, can solve problems such as uneven lubricant, production time occupation, and mandrel cannot be rotated, so as to improve the degree of mechanical automation, prolong the service life and shorten the production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

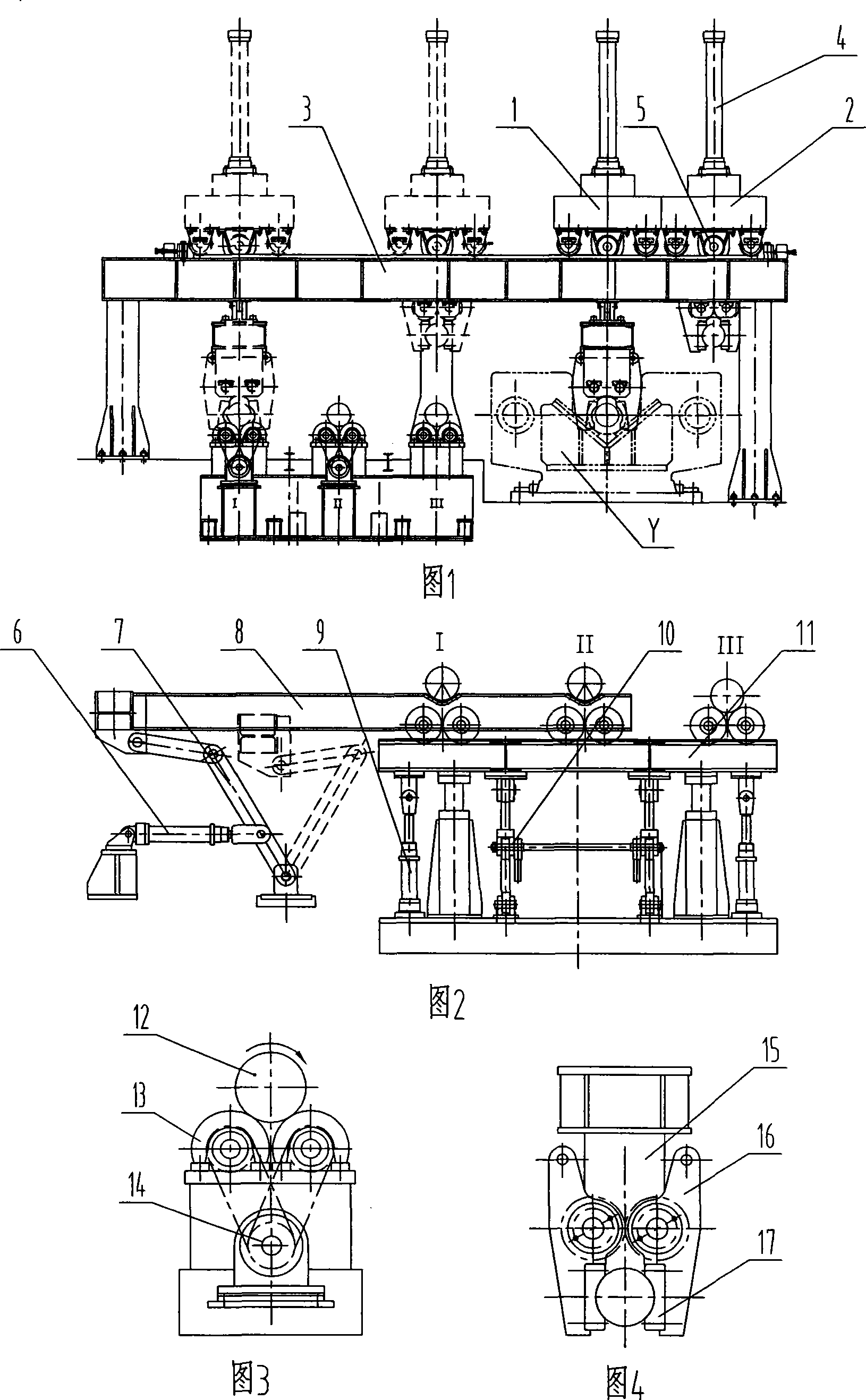

[0015] As shown in Figures 1 and 2, a mandrel circulation device for a drawing press is composed of a supporting roller support device, two transport trolleys and a stepping mechanism, and a cooling unit is installed horizontally outside the drawing press Y. Station I, lubricating station II, waiting station III; the mandrel 12 of each station is supported by the idler 13, and the idler 13 of the cooling station I and lubricating station II is driven by the motor reducer 14 and can be driven The mandrel rotates around its own axis, and two track beams 3 are erected above the mandrel. Two transport trolleys 1 and 2 run on the two track beams 3. The trolley is equipped with a lifting device 4, and a clamp 16 is installed under the lifting device. The lifting device can move up and down, and the clamp can be opened and closed.

[0016] A stepping mechanism is set between the three mandrel stations, and four sets of vertical jacking cylinders 9 are connected with the track 11 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com