Novel strong lubrication floating core head assembly

A new technology of floating core, applied in the direction of the mandrel, etc., can solve the problems of fast wear of the floating core, accelerated wear of the floating core, and pollution of the surrounding environment, so as to avoid ring-shaped corrugated waste products and reduce power consumption , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

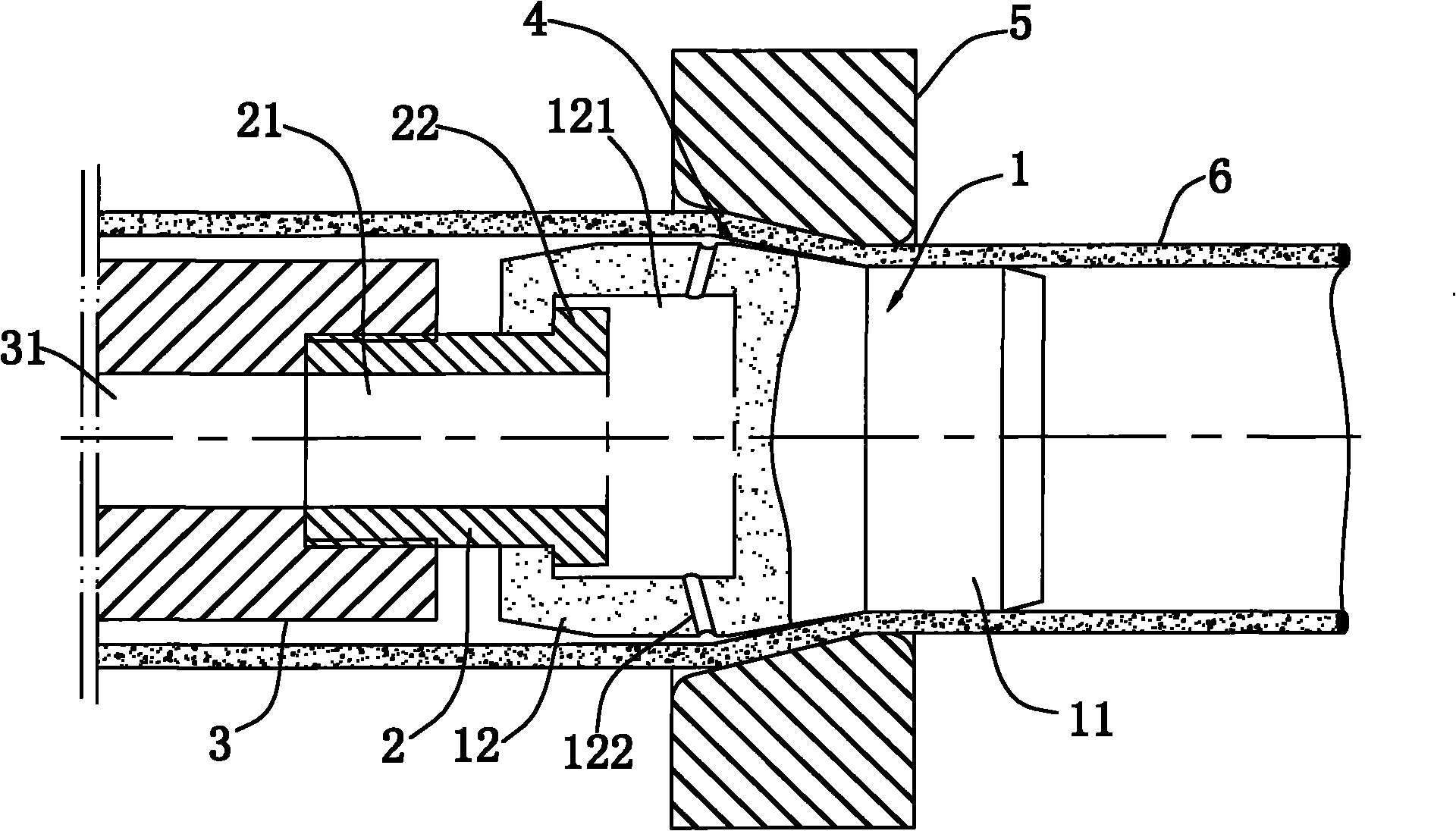

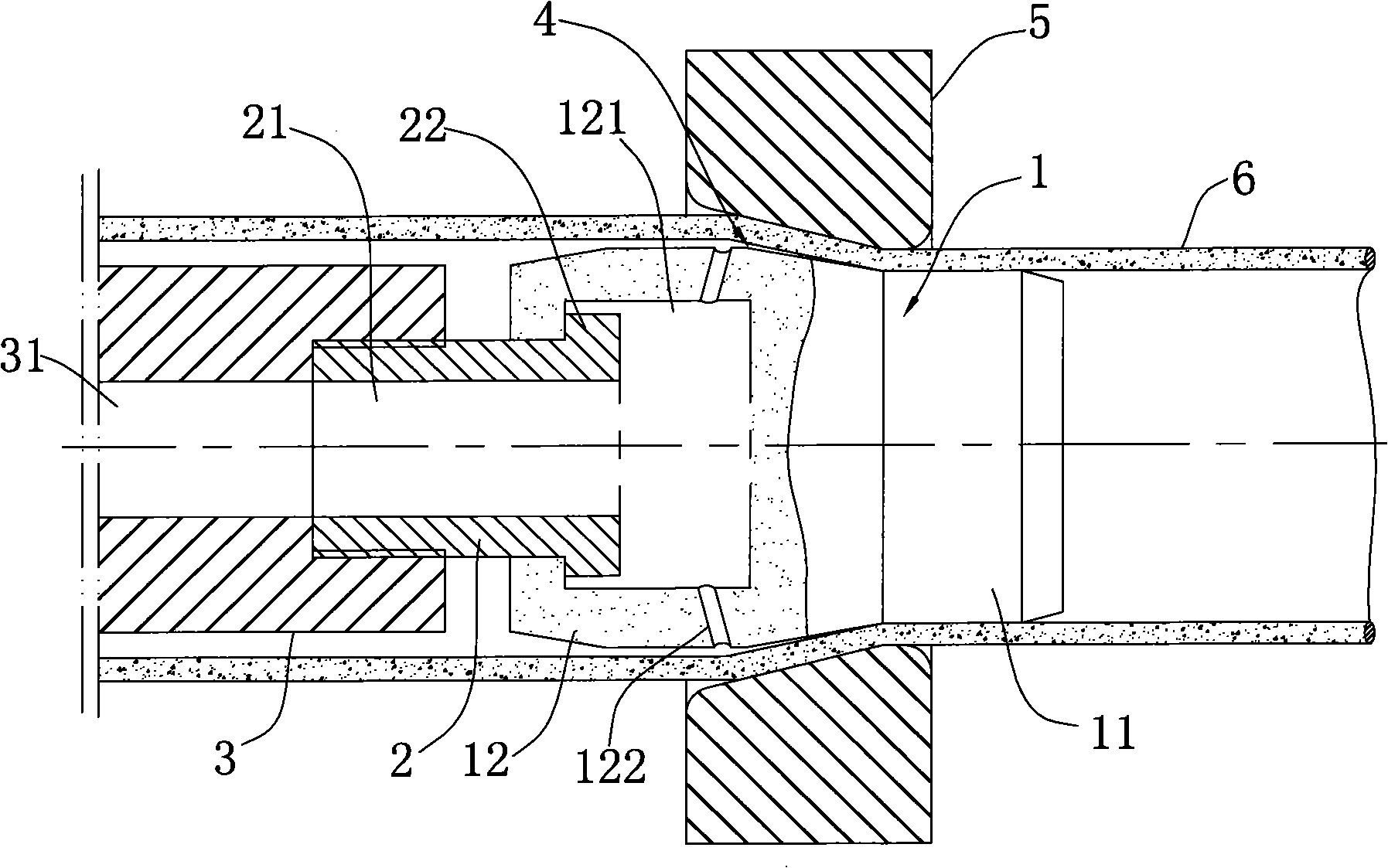

[0018] Such as figure 1 As shown, the present invention provides a novel strongly lubricated traveling mandrel assembly, comprising a stretching mandrel 3, a traveling mandrel 1 and a connecting screw 2 for connecting the drawing mandrel 3 and the traveling mandrel 1, The stretching mandrel 3 is provided with an oil passage I 31, the swimming core 1 is provided with an oil storage chamber 121, and the connecting screw 2 is provided with a communication oil passage I 31 and an oil storage chamber 121. There are several oil injection holes 122 communicated with the oil storage chamber 121 in the radial direction on the wall of the floating core head 1 . The floating core 1 is composed of a finishing section 11 for controlling the size of the pipe material 6 and a working section 12 for shaping and guiding. The working section 12 is connected with the connecting screw 2, and the oil storage chamber 121 is located in the working section. Inside section 12; the shape of working se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com