Thermal expansion machine for producing stainless steel tube

A technology for stainless steel pipe and steel pipe diameter expansion, which is applied in the direction of manufacturing tools, metal processing equipment, forming tools, etc., can solve the problems of difficult control of stainless steel heating, large thermal expansion and contraction deformation, etc., to improve physical properties and metallographic structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

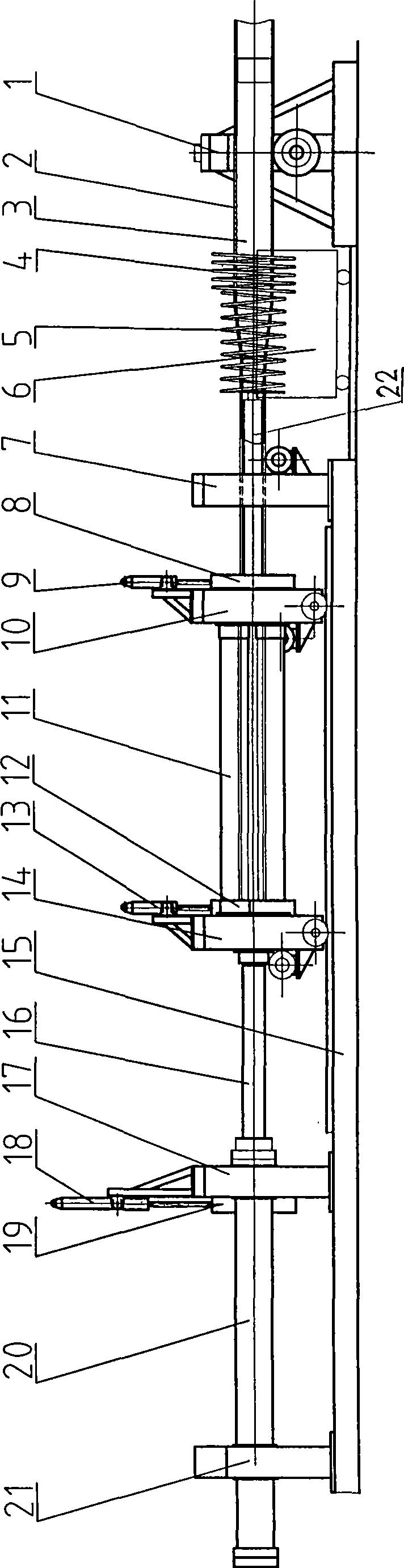

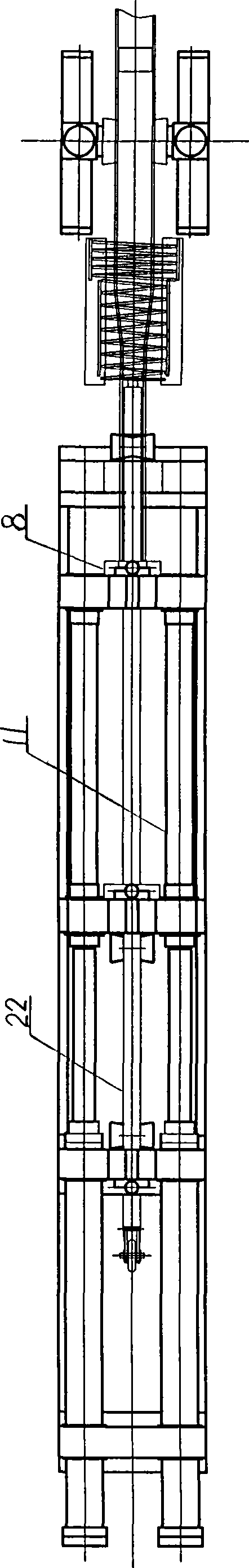

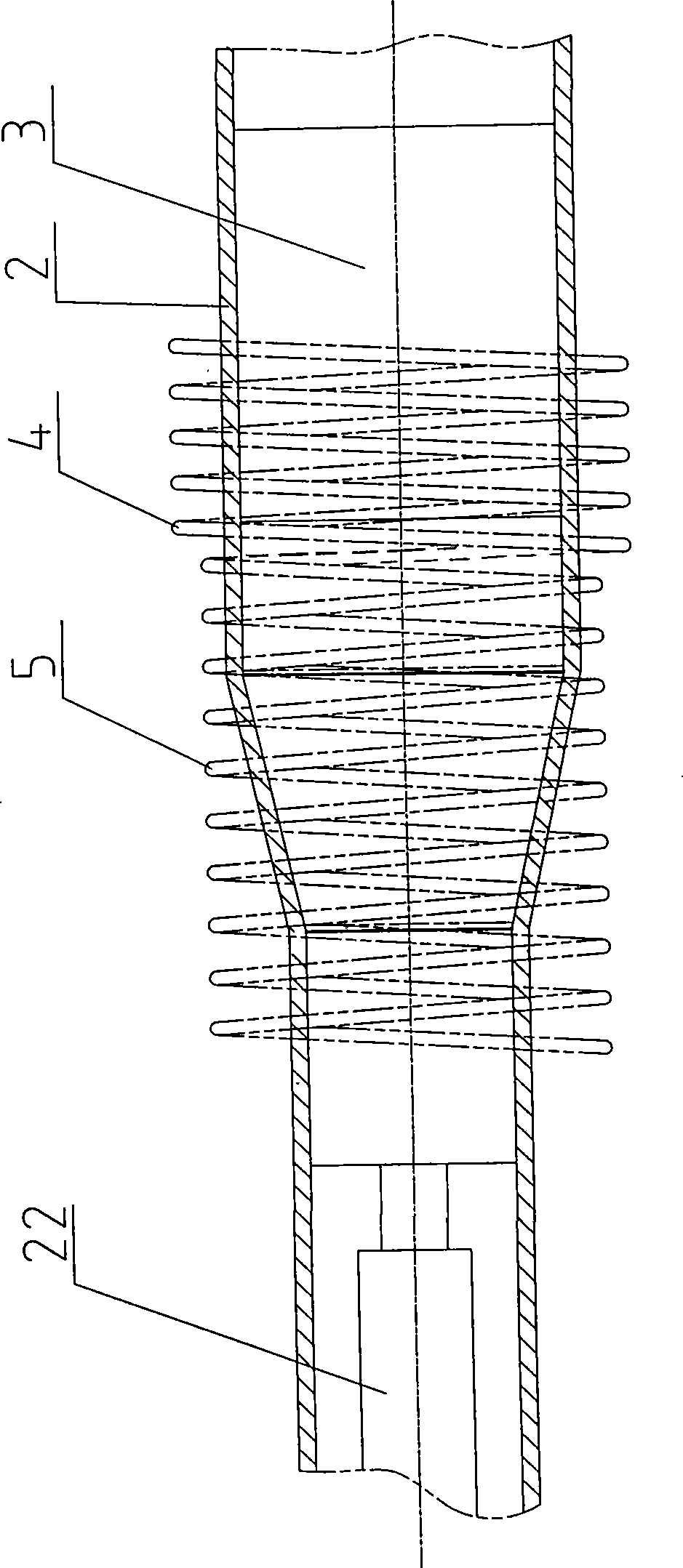

[0010] The specific structure and working principle of the present invention are illustrated below in conjunction with the embodiments given in the accompanying drawings.

[0011] As shown in the accompanying drawings, the stainless steel pipe thermal expansion pipe making machine of the present invention includes a bracket 21, a support plate 17, a rear push plate 14, a front push plate 10, and a front support arranged sequentially on the base 15 from back to front. plate 7, the hydraulic cylinder 20 is fixed on the bracket 21 and the support plate 17, the rear push plate 14 is fixed on the front end of the plunger rod 16 on the hydraulic cylinder 20, one end of the push rod 11 is fixed on the rear push plate 14, and the other end is fixed On the front push plate 10, it is characterized in that there is a core mold support 1 in front of the front support plate 7, an intermediate frequency induction heating coil device 6 is arranged between the front support plate and the core ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Frequency | aaaaa | aaaaa |

| Inductance | aaaaa | aaaaa |

| Inductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com