Production process of waterproof polyving akohol film and application for obtaining waterproof polyving akohol film

A polyvinyl alcohol film and production process technology, which is applied in the field of plastic films, can solve the problems of easy residue of harmful substances, low production efficiency, and impact on use safety, achieve good barrier effect of harmful substances, avoid film surface defects, and improve product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Take 100kg of 1799 polyvinyl alcohol resin and put it into a thermal mixer with 95°C jacket heating. Add 70 kg of water and 0.2 kg of sodium dodecylsulfonate, and stir for 1 hour at a speed of 5 rpm to obtain swollen polyvinyl alcohol particles.

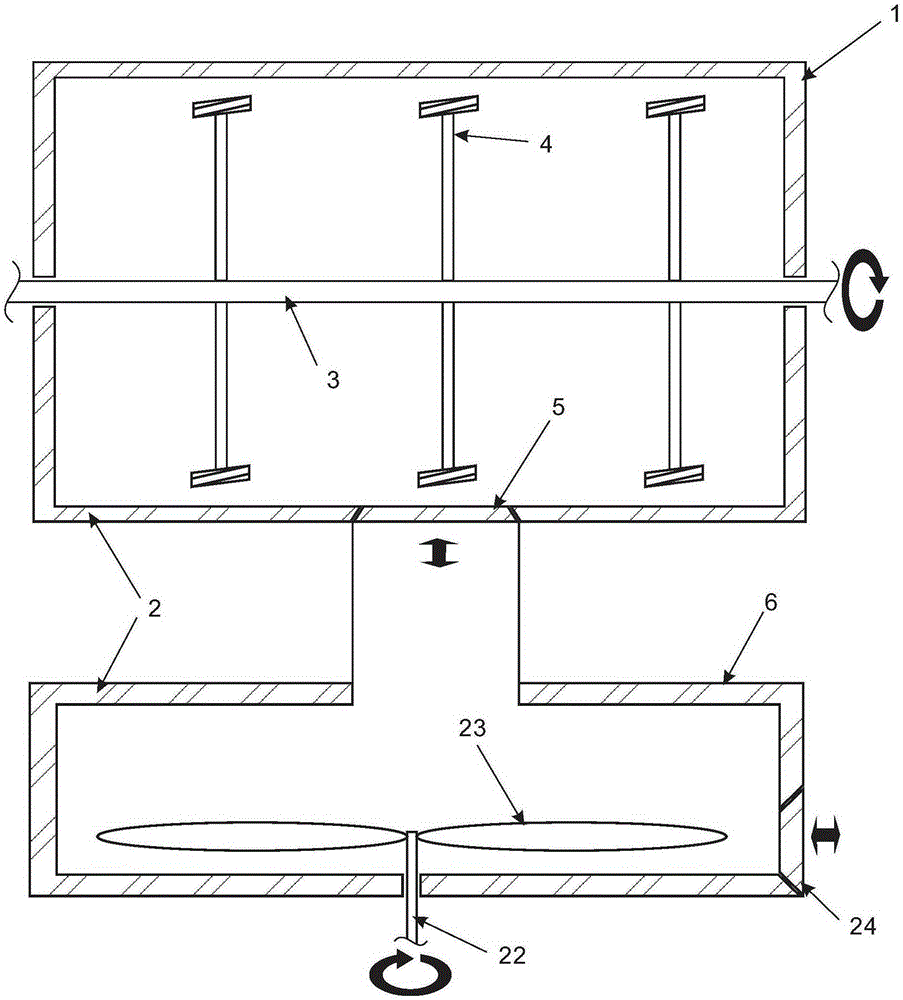

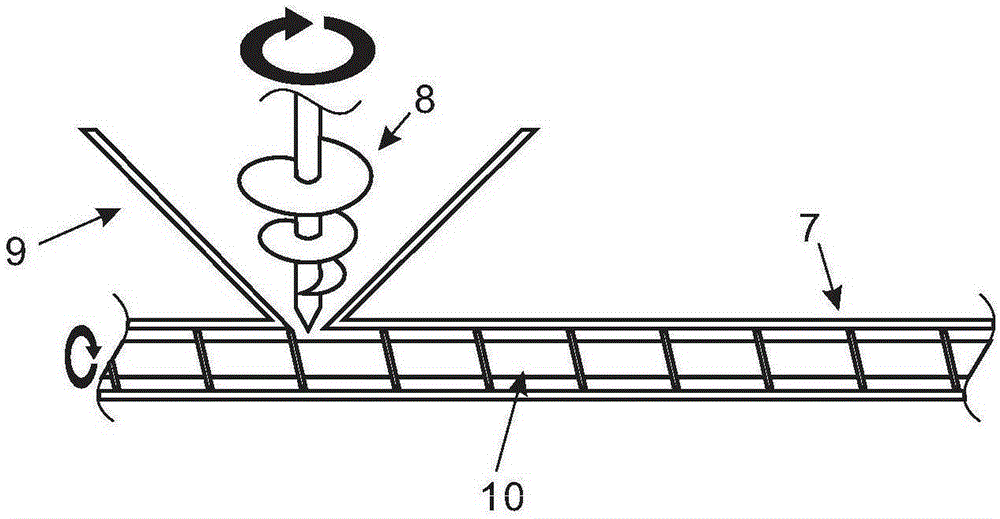

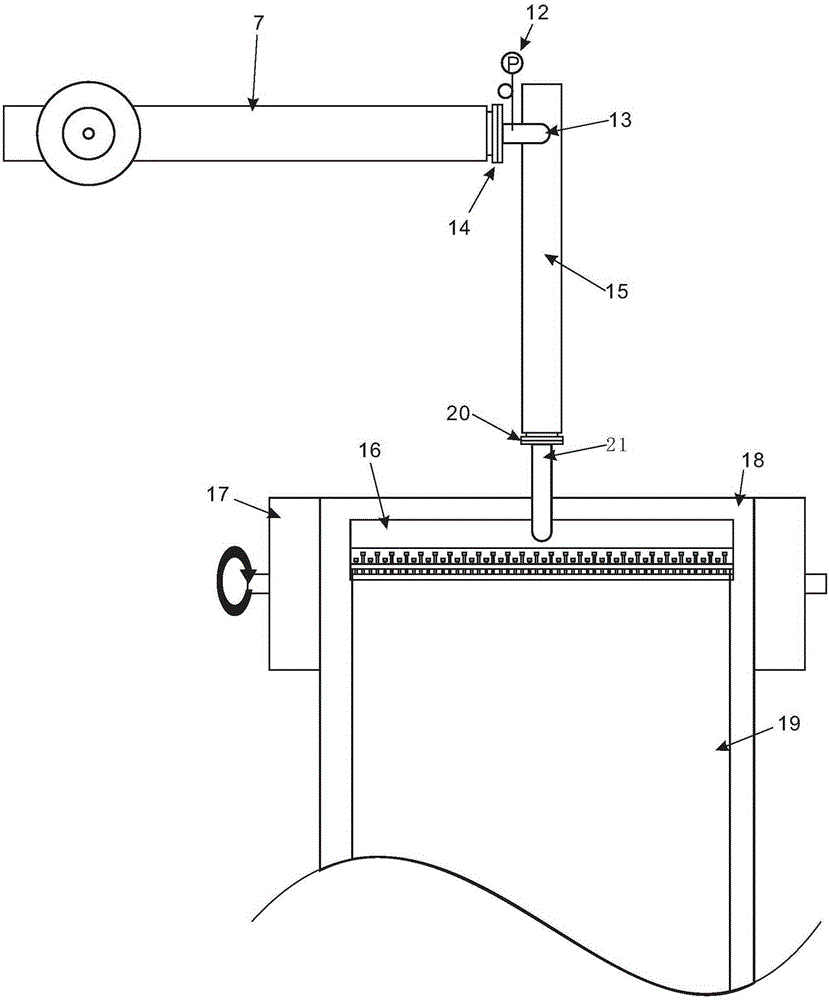

[0052] The mixed polyvinyl alcohol swollen granules are quickly transferred to a cooling mixer and cooled to room temperature. The cooled polyvinyl alcohol swollen granules are fed into the feed hopper of a twin-screw extruder equipped with a vertical forced feeding slurry. The specification of the twin-screw extruder is a twin-screw extruder with a diameter of 45mm and a length-to-diameter ratio of 40:1 co-rotating combined screw (referred to as a co-rotating twin-screw extruder), 7-stage temperature control, and an open-type discharge in the metering section. The air port is set to 100°C except that the temperature of the feeding section is set to 60°C, and the outlet flange is set to 105°C. The filter screens are double-la...

Embodiment 2

[0055] Take 100kg of 1799 polyethylene and put it into a thermal mixer with jacket heating at 90°C. Add 200 kg of water, 15 kg of glycerin, and 1.5 kg of polyoxyethylene lauryl ether, stir at a speed of 90 rpm for 0.5 hour, cool down to 80° C. and continue stirring for 3 hours to obtain swollen polyvinyl alcohol particles.

[0056] The mixed polyvinyl alcohol swollen granules are quickly transferred to a cooling mixer and cooled to room temperature. The cooled polyvinyl alcohol swollen granules are fed into the hopper of a twin-screw extruder equipped with a vertical forced feed slurry. The specification of the twin-screw extruder is a twin-screw extruder with a diameter of 45mm and a length-to-diameter ratio of 40:1. ℃, the rest are set to 85 ℃, the outlet flange is 90 ℃, the filter screen adopts 60 / 100 mesh double layer, the screw speed is automatically adjusted according to the pressure of the heat preservation feeding pipe, the range is 25-500 rpm, the inside of the barre...

Embodiment 3

[0059] Take 100kg of 1799 polyethylene and put it into a thermal mixer with jacket heating at 90°C. Add 90 kg of water, 0.4 kg of polyoxyethylene lauryl ether, and 10 kg of butanediol, and stir for 2 hours at a speed of 20 rpm to obtain swollen polyvinyl alcohol particles.

[0060] The mixed polyvinyl alcohol swollen granules are quickly transferred to a cooling mixer and cooled to room temperature. The cooled polyvinyl alcohol swollen granules are fed into the hopper of a twin-screw extruder equipped with a vertical forced feed slurry. The specification of the twin-screw extruder is a twin-screw extruder with a diameter of 45mm and a length-to-diameter ratio of 40:1. ℃, the rest are set to 95 ℃, the outlet flange is 100 ℃, the filter screen adopts 60 / 100 mesh double layer, the screw speed is automatically adjusted according to the pressure of the heat preservation feeding pipe, the range is 15-30 rpm, the inside of the barrel The pressure is 1.2MPa, and the temperature of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com