Coal seam extraction drilling hot-cold impacting coal-breaking permeability-increasing device and permeability-increasing method

A drainage drilling, hot and cold technology, applied in the direction of safety devices, mining fluids, mining equipment, etc., can solve the problem of limited range of inert gas freezing and high-pressure shock anti-reflection, small number of coal seam cracks, small drainage coverage, etc. To solve the problem, achieve the effect of simple and flexible equipment structure and implementation method, improve the flow rate of drilling gas drainage, and overcome the effect of insufficient fracturing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

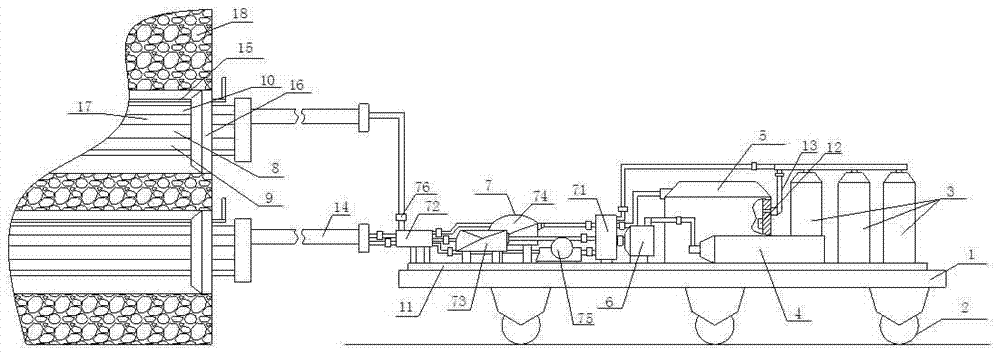

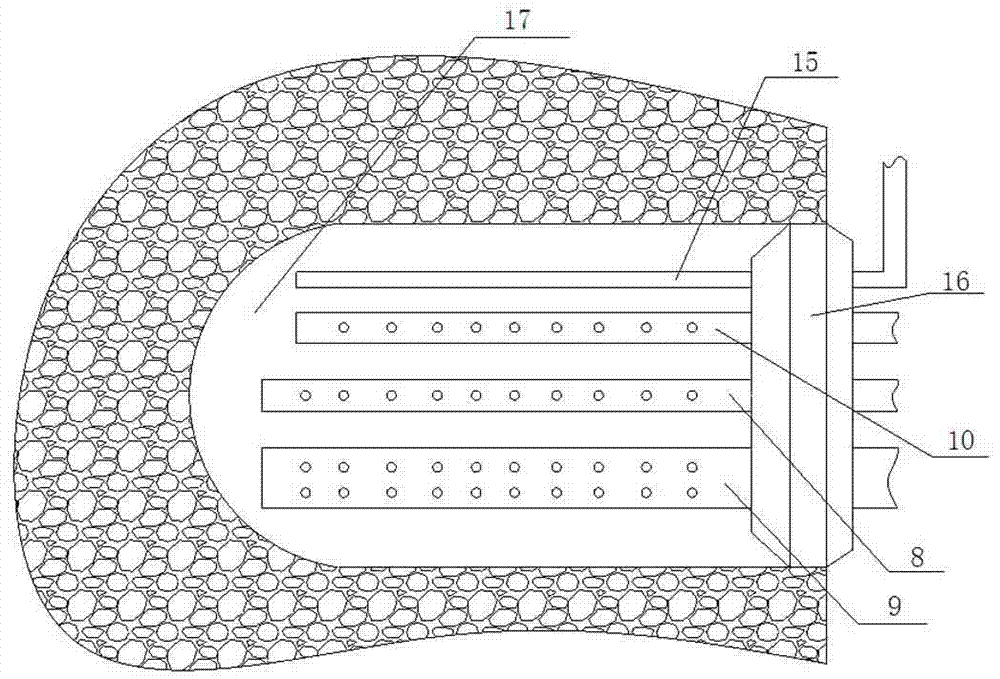

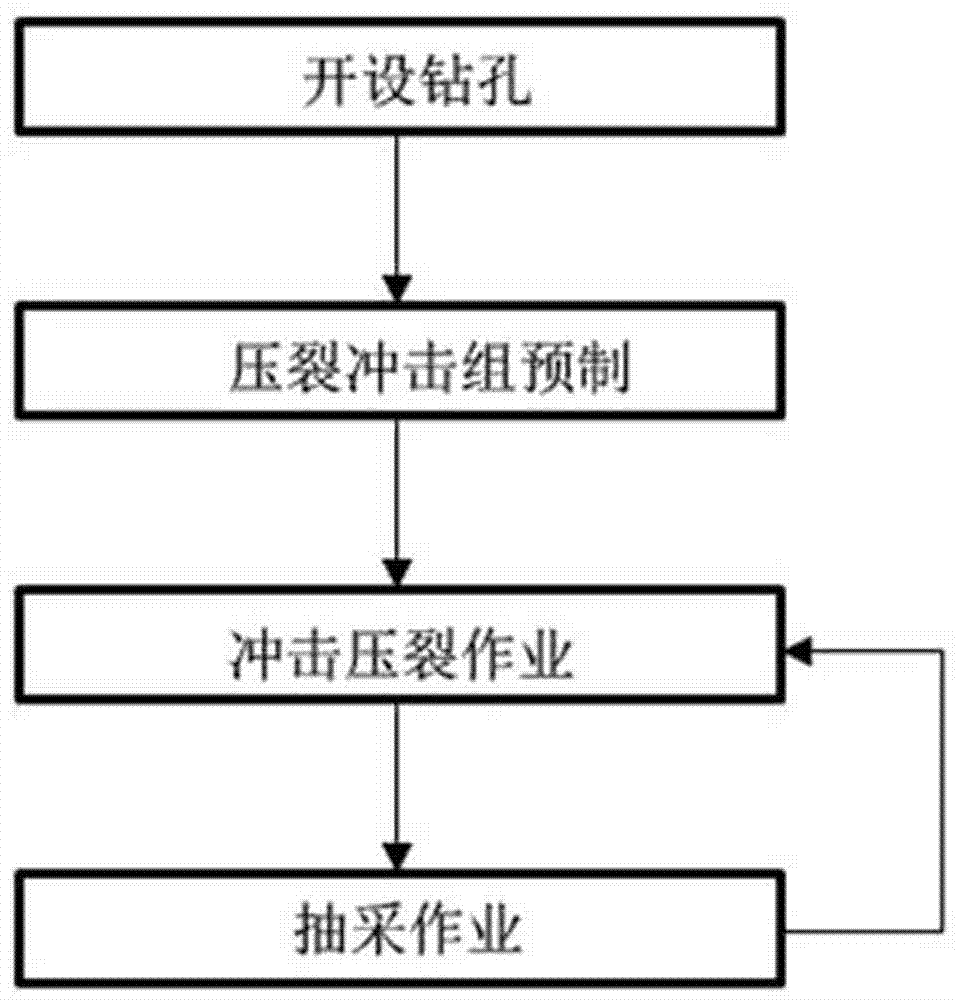

[0023] Such as figure 1 and 2 The coal seam extraction drilling hot-cold impact coal breaking and anti-reflection increasing device includes a bearing base 1, a traveling mechanism 2, a liquid nitrogen storage cylinder 3, a gaseous nitrogen storage cylinder 4, a water storage tank 5, a hot air blower 6, a booster Pressure pump group 7, nitrogen heating pipe 8, water cooling pipe 9 and liquid nitrogen cooling pipe 10, the lower surface of the bearing base 1 is connected to the running mechanism 2, and the running mechanism 2 is distributed around the axis of the bearing base 1, the liquid nitrogen storage cylinder 3, gaseous nitrogen The storage cylinder 4, the water storage tank 5, the hot air blower 6 and the booster pump set 7 are all slidably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com