A cost-benefit intelligent control method for adding drag-reducing fluid to mine water ring vacuum pumps

A mining water and vacuum pump technology, which is applied to components, pumps, and pump components of elastic fluid pumping devices, can solve the problems of high energy saving effect, reduced economic benefits, liquid level and viscosity fluctuations, etc., and achieve The effect of minimizing and maximizing cost, solving high investment cost and maximizing energy-saving benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

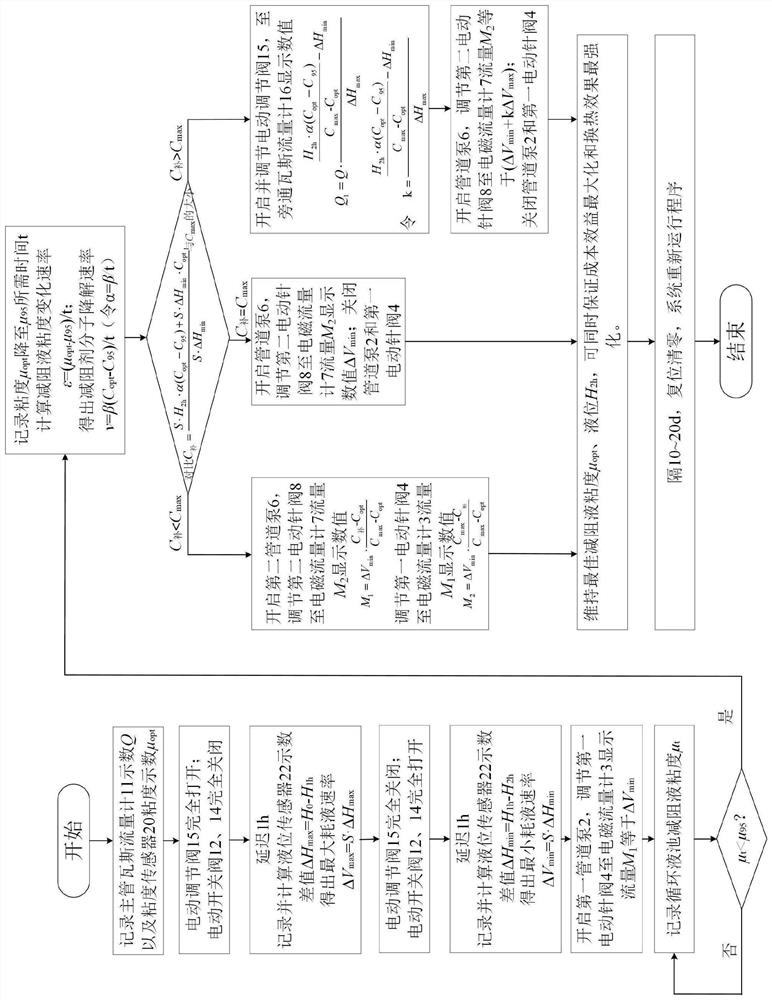

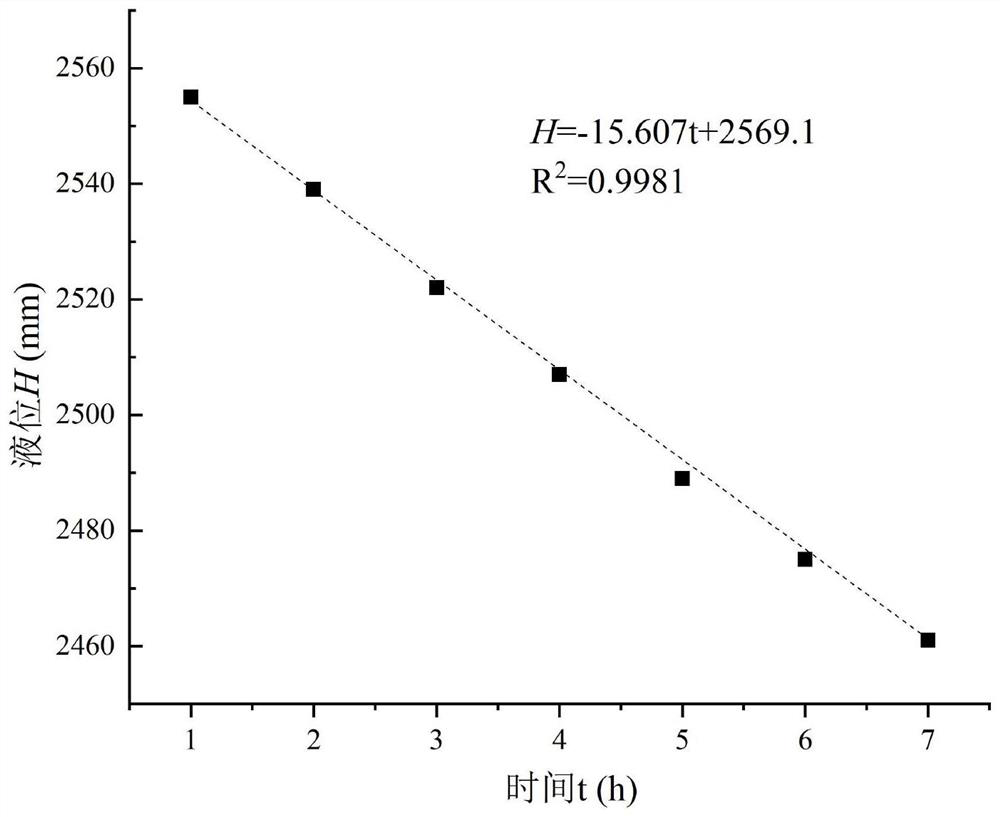

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

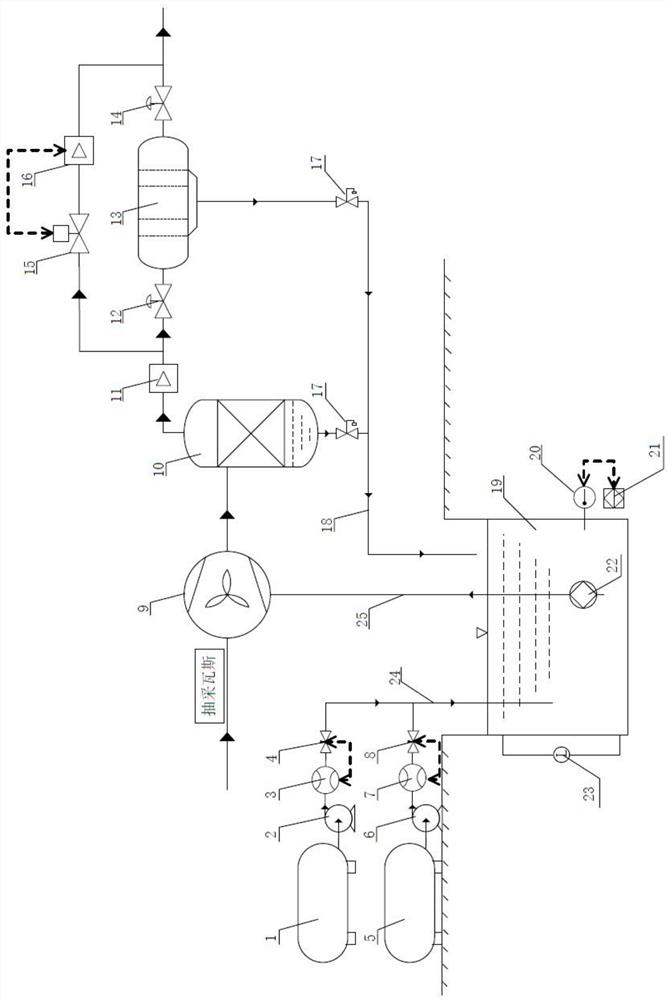

[0033] Such as figure 1As shown, the present invention firstly provides a cost-benefit intelligent control system for adding drag reducing fluid to a water ring vacuum pump, including a concentrated liquid storage tank 1, an optimal solution storage tank 5, a water ring vacuum pump 9, and a first-stage gas-liquid separator 10. Second stage gas-liquid separator 13, circulating liquid pool 19;

[0034] The discharge port of the water ring vacuum pump 9 is connected to the inlet of the first-stage gas-liquid separator 10, and the gas outlet of the first-stage gas-liquid separator 10 is connected to the main gas flow meter 11 and then divided into two branches. The first electric on-off valve 12, the second-stage gas-liquid separator 13, and the second electric on-off valve 14 are connected in sequence, and the other branch is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com