Low-temperature coal economizer optimal operation control system and control method thereof

A low-temperature economizer and control system technology, which is used in the control of feed water, feed water heaters, preheating, etc., can solve the problem of installing flow measurement devices, unable to understand the water side flow of the low-temperature economizer, and not knowing the opening of valve A, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

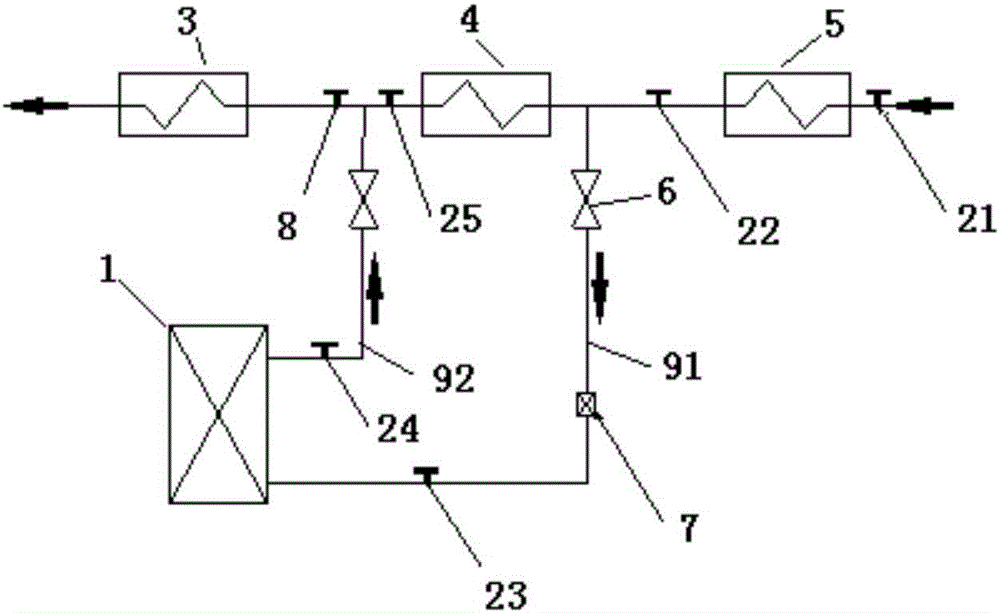

[0040] A low-temperature economizer 1 optimal operation control system, including a low-temperature economizer 1, a water-side inlet pipeline 91 and a water-side outlet pipeline 92, and the low-temperature economizer 1 passes through the water-side inlet pipeline 91 The connecting pipeline 92 on the water side is connected across the two ends of the recuperation heater 4, and the control valve 6 is installed on the water-side connecting pipeline 91 at the inflow end of the low-temperature economizer 1, which is characterized in that: A condensate flowmeter 7 is also provided on the pipeline 91, and the condensate flowmeter 7 is installed on the downstream side of the control valve 6, and a No. Temperature instrument 22, the No. 2 temperature instrument 22 is set on the upstream side of the inlet of the water side access pipeline 91, and No. 3 temperature instrument 23 is installed on the downstream side of the condensate flow meter 7, and the pipeline is connected to the water ...

Embodiment 2

[0045] The present invention also provides a control method for the optimal operation control system of the above-mentioned low-temperature economizer 1, which is characterized in that the steps are as follows:

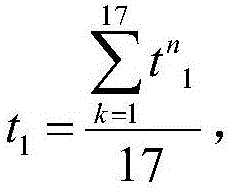

[0046] Step 1. Adjust the opening of the control valve 6 to 20% through the DCS control system, and calculate the heat absorption Q of the low-temperature economizer 1 under the current state DW-1 , record the flow q of the condensate flowmeter 7 in the current state 1 ;

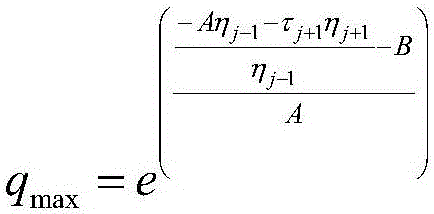

[0047] Q DW-1 =q 1 (h 1 smq -h 1 j+1 )

[0048] where h 1 smq is the current inlet water enthalpy value of low-temperature economizer 1, and is the temperature obtained by No. 4 temperature meter 24 in the current state and the acquired pressure P of the pressure gauge 8 1 , obtained by using the water vapor function formula, h 1 j+1 is the current outlet enthalpy value of low-temperature economizer 1, and is the temperature obtained by No. 3 temperature instrument 23 in the current st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com