Thermal power plant direct air cooling unit dead steam waste heat recovery heat supply system

An air-cooling unit and waste heat recovery technology, applied in the field of energy saving in power plants, can solve problems such as heat waste and energy consumption, and achieve the effects of improved energy saving effect, far and flexible operation mode, and reasonable matching of thermal system parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

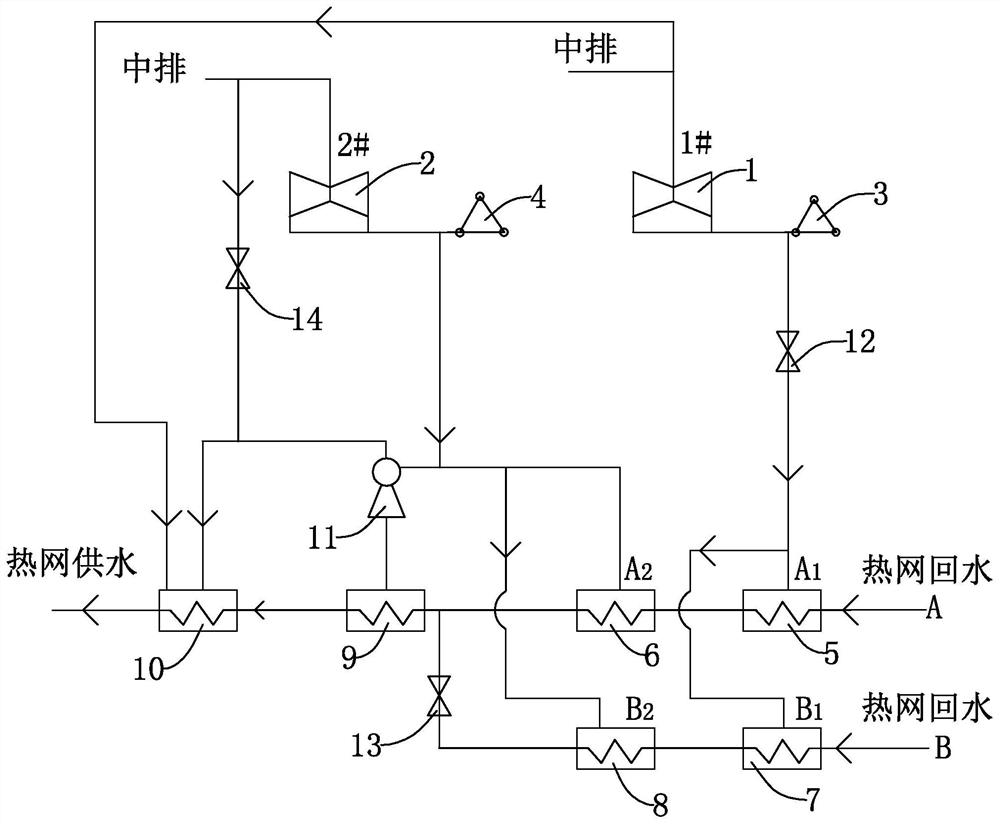

[0031] The following is attached figure 1 The application is described in further detail.

[0032] The embodiment of the present application discloses a thermal power plant direct air-cooling unit exhaust steam waste heat recovery heating system. refer to figure 1, the waste steam waste heat recovery heating system includes two independently set steam turbines, the exhaust steam extraction system, the air-cooled steam system corresponding to each steam turbine, and the dual-channel heating network water cascade heating system. The air-cooled steam system is connected to each The steam turbine is connected, and the exhaust steam extraction system can lead the exhaust steam from the exhaust pipe of the low-pressure cylinder of the steam turbine. The two steam turbines include the No. 1 steam turbine 1 and the No. The heat of steam comes from the exhaust steam at the end of the medium-pressure cylinder of the steam turbine. The No. 1 steam turbine 1 and the No. 2 steam turbine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com