Electromagnetic stirrer for continuous casting solidification end and dynamic control method thereof

An electromagnetic stirrer and solidification end technology, which is applied in the field of steel continuous casting production, can solve the problems of insufficient stirring capacity of the electromagnetic stirrer, unstable electromagnetic stirring effect at the end of the continuous casting billet, etc., and achieves low power consumption, stable magnetic field and high efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

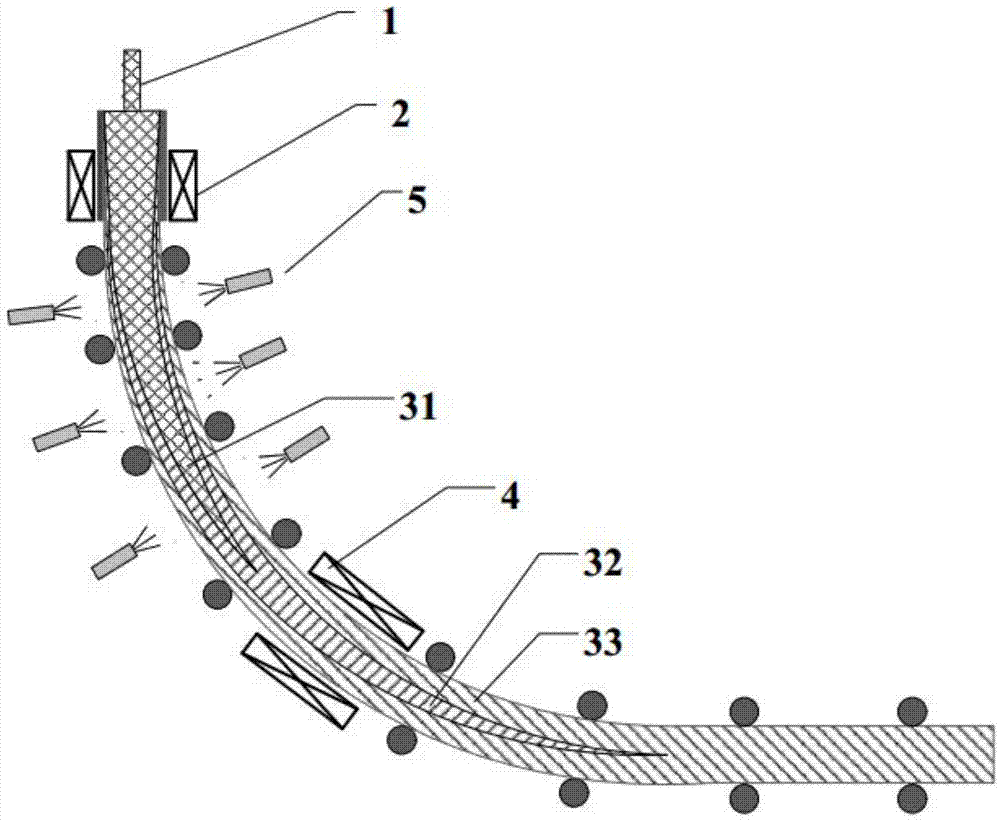

[0030] figure 1 It is a schematic diagram of the bloom continuous casting process of the present invention. The high-temperature liquid steel enters the mold 2 through the immersion nozzle 1 for primary cooling. At this time, it is in the liquid phase zone 31. After cooling, a billet 33 with a certain thickness is formed on the surface and pulled from the mold 2 After entering the secondary cooling zone, the second cooling is carried out under the action of spraying water from the nozzle 5, and the continuous casting billet 3 billet shell 33 is continuously thickened, the liquid phase in the liquid core gradually disappears, and the liquid cavity becomes the two-phase zone 32. The billet with a certain thickness of the billet shell 33 passes through the electromagnetic stirrer 4 at the end of the solidification, and generates an induced electromagnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com