Preparation method of pre-dispersed carbon nano-tube rubber masterbatches

A carbon nanotube and pre-dispersion technology, applied in the field of materials, can solve problems such as difficult transportation, heavy pollution, and unsatisfactory demand, and achieve the effects of reduced volume resistivity, improved tear strength, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

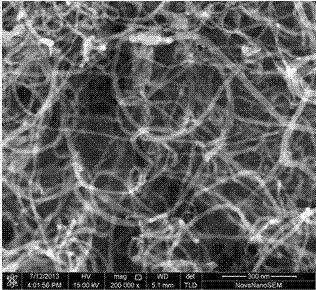

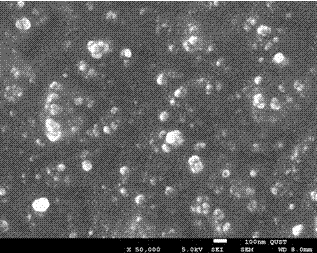

[0053] Add 20 parts of multi-walled carbon nanotubes into a pressure-resistant glass reactor, add 10-20 parts of maleic anhydride, seal the reactor, raise the temperature of the oil bath to 150-200° C. and react for 8-20 hours. After the reaction, cool to room temperature, wash the reaction mixture with toluene and methanol respectively, filter, and vacuum-dry the filter cake at 60°C overnight to obtain surface-modified multi-walled carbon nanotubes;

[0054] Mix the above-mentioned carbon nanotubes with 100 parts of plasticized natural rubber, 5 parts of microcrystalline wax, 5 parts of stearic acid, 1 part of anti-aging agent, and 1 part of activator in an internal mixer and an open mixer according to a certain rubber mixing process. Uniform refining to obtain high-concentration pre-dispersed carbon nanotube rubber composites;

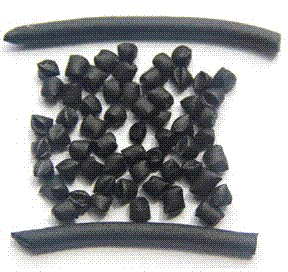

[0055] The above-mentioned pre-dispersed carbon nanotube rubber composite material is made into rubber strips, added to a single-screw rubber extrud...

Embodiment 2

[0061] Weigh 80 parts of multi-walled carbon nanotubes and add them into a pressure-resistant glass reactor, then add 40-80 parts of dicyclopentadiene, seal the reactor, and raise the temperature to 150-200° C. for 6-10 hours. After the reaction, cool to room temperature, wash the reaction mixture with toluene and methanol respectively, filter, and vacuum-dry the filter cake at 60°C overnight to obtain surface-modified multi-walled carbon nanotubes;

[0062] Mix the above-mentioned carbon nanotubes with 10 parts of masticated natural rubber, 20 parts of microcrystalline wax, 10 parts of stearic acid, 1 part of anti-aging agent, and 1 part of activator in an internal mixer and an open mixer according to a certain rubber mixing process. Uniform refining to obtain high-concentration pre-dispersed carbon nanotube rubber composites;

[0063] The above-mentioned pre-dispersed carbon nanotube rubber composite material is made into rubber strips, added to a single-screw rubber extrude...

Embodiment 3

[0069] Weigh 50 parts of multi-walled carbon nanotubes and add them into a pressure-resistant glass reactor, then add 20-40 parts of dicyclopentadiene, seal the reactor, and raise the temperature to 150-200° C. for 6-10 hours. After the reaction, cool to room temperature, wash the reaction mixture with toluene and methanol respectively, filter, and vacuum-dry the filter cake at 60°C overnight to obtain surface-modified multi-walled carbon nanotubes;

[0070] Mix the above-mentioned carbon nanotubes with 20 parts of masticated natural rubber, 10 parts of microcrystalline wax, 10 parts of stearic acid, 1 part of anti-aging agent, and 1 part of activator in an internal mixer and an open mixer according to a certain rubber mixing process. Uniform refining to obtain high-concentration pre-dispersed carbon nanotube rubber composites;

[0071] The above-mentioned pre-dispersed carbon nanotube rubber composite material is made into rubber strips, added to a single-screw rubber extrude...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com