Negative electrode active material for nonaqueous electrolyte secondary batteries and method for producing same

一种负极活性物质、非水电解质的技术,应用在非水电解质二次电池领域,能够解决无法充分发挥特性等问题,达到不可逆容量小、电极崩坏缓和、良好循环性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

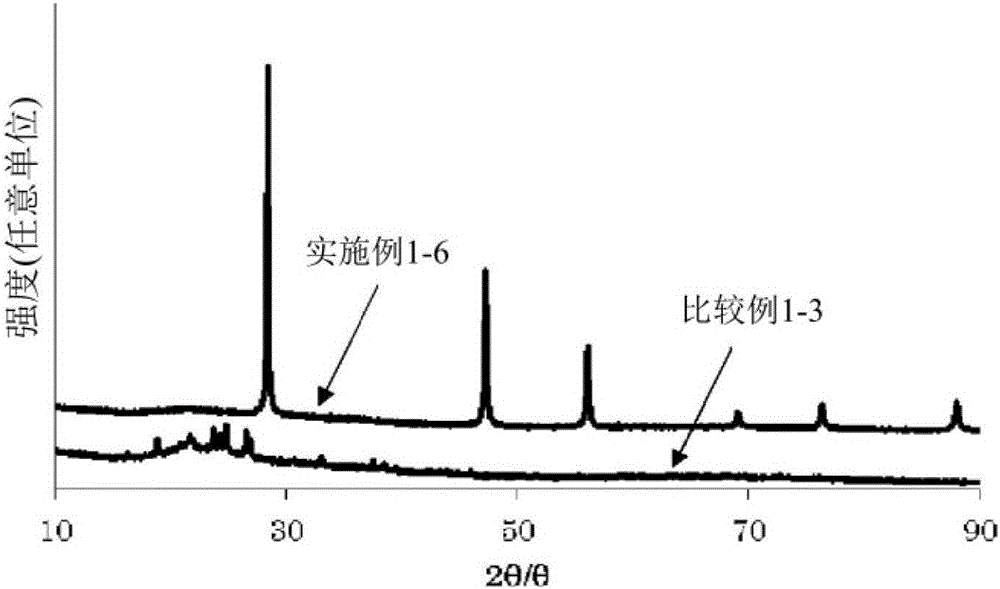

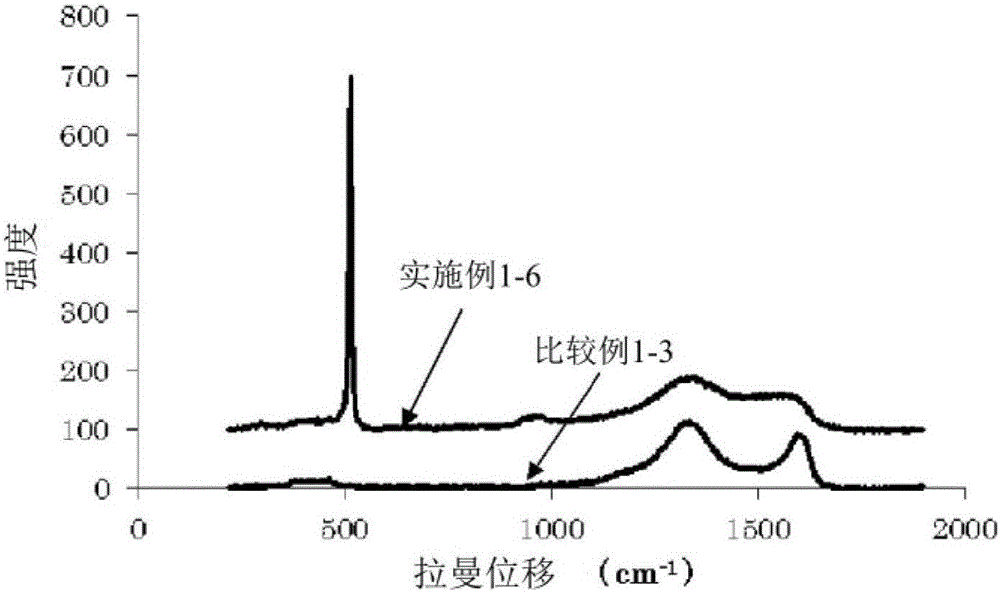

[0091] First, a first embodiment of the present invention will be described.

[0092] The negative electrode active material for the non-aqueous electrolyte secondary battery of the first embodiment of the present invention is composed of the element composition formula Met 1 -Si-O-C-H said. Met in the element composition formula 1 It is one or a mixture of alkali metal elements. This negative electrode active material contains a silicate composed of a silicon-based inorganic compound and an alkali metal, and microparticles composed of silicon, silicon alloy, or silicon oxide (hereinafter also simply referred to as "silicon-based particles") are dispersed in the silicate. The alkali metal element is preferably Li or Na. Preferably, the silicate further contains Group 3 to Group 13 metals. The Group 3 to Group 13 metal is more preferably a first transition metal or a second transition metal. In the negative electrode active material of the present invention, furthermore, c...

no. 2 Embodiment approach

[0123] Next, a second embodiment of the present invention will be described. Descriptions of the same items as in the first embodiment are omitted.

[0124] The negative electrode active material for the non-aqueous electrolyte secondary battery of the 2nd embodiment of the present invention is by element composition formula Met 2 -Si-O-C-H said. Met in the element composition formula 2 It is one or a mixture of alkaline earth metal elements. This negative electrode active material contains a silicate composed of a silicon-based inorganic compound and the alkaline earth metal. The alkaline earth metal element used here is preferably Mg or Ca. In addition, in the negative electrode active material of the present invention, it is preferable that the silicate further contains Group 3 to Group 13 metals. More preferably, the Group 3 to Group 13 metal is a first transition metal or a second transition metal. In the negative electrode active material of the present invention, ...

Embodiment 1-1

[0153] 10 g of polycrystalline metal silicon particles with an average particle diameter of 0.2 μm and 150 g of methyl vinyl siloxane having a viscosity of 60,000 cp represented by the following chemical formula (1) were charged into a 1 L container of a twin-shaft planetary mixer, And 10g of lithium carbonate, kneading for 1 hour with a rotation speed of 30rpm. Add 0.8 g of Shin-Etsu Chemical Co., Ltd. containing 80% by mass of 2,5-dimethyl-2,5 bis(t-butylperoxy)-hexane. ) using a vulcanizing agent (trade name: C-8A) as a vulcanizing agent, and a curing reaction was performed at 150° C. for 1 hour. The solidified product obtained after cooling was gray-brown resin, and the yield was 98.9%. Next, after pulverizing the obtained cured product to a diameter of about 1 mm, 100 g of the pulverized product was put into an alumina crucible with an internal volume of 280 mL, and calcined at 1000° C. in a muffle furnace for 1 Hour. The obtained calcined product is a black glass-like...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com