Application and preparation method of biomass-based nitrogen-doped porous carbon

A nitrogen-doped porous carbon and biomass technology, applied in the direction of carbon preparation/purification, chemical instruments and methods, alkali metal compounds, etc., can solve problems that are not suitable for large-scale production and industrial applications, complex preparation processes, and expensive precursors and other problems, to achieve high adsorption capacity, simple process, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

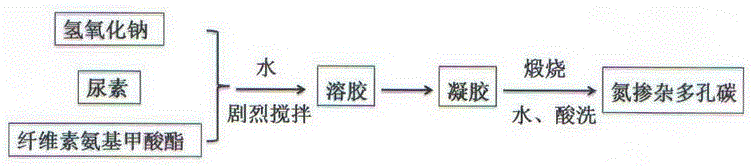

[0066] a. Dissolve 5g of sodium hydroxide in 50ml of water and stir to dissolve, add 15g of urea and stir to dissolve, at a temperature of 10°C, add 5g of cellulose carbamate, and mechanically stir vigorously for 12min to obtain a uniform cellulose carbamate / Urea / sodium hydroxide sol solution, and then put the sol solution in an evaporating dish, spread it flat, and dry it at a temperature of 80°C for 5 hours to obtain a sol;

[0067]b. Under the protection of nitrogen, put the dried sol in step a into a tube furnace for calcination, raise the temperature to 550°C at a rate of 5°C / min, keep it for 1h, then raise the temperature to 700°C, and keep it for 1h. A black solid was obtained, and then the black solid was washed with water and 10 wt % hydrochloric acid until neutral, and dried at 120° C. for 4 hours to obtain biomass-based nitrogen-doped porous carbon.

Embodiment 2

[0069] a. Dissolve 5g of sodium hydroxide in 50ml of water and stir to dissolve, add 15g of urea and stir to dissolve, at a temperature of 8°C, add 5g of cellulose carbamate, and mechanically stir vigorously for 10min to obtain a uniform cellulose carbamate / Urea / sodium hydroxide sol solution, and then put the sol solution in an evaporating dish, spread it flat, and dry it at a temperature of 60°C for 6 hours to obtain a sol;

[0070] b. Under the protection of nitrogen, place the dried sol in step a for calcination in a tube furnace, raise the temperature to 550°C at a rate of 5°C / min, keep it for 1h, then raise the temperature to 800°C, and keep it for 1h. A black solid was obtained, and then the black solid was washed with water and 10 wt % hydrochloric acid until neutral, and dried at 120° C. for 4 hours to obtain biomass-based nitrogen-doped porous carbon.

Embodiment 3

[0072] a. Dissolve 5g of sodium hydroxide in 50ml of water and stir to dissolve, add 15g of urea and stir to dissolve, at a temperature of 15°C, add 5g of cellulose carbamate, and mechanically stir vigorously for 15min to obtain a uniform cellulose carbamate / Urea / sodium hydroxide sol solution, and then put the sol solution in a 50ml beaker, spread it flat, and dry it at a temperature of 70°C for 9 hours to obtain a sol;

[0073] b. Under the protection of nitrogen, place the dried sol in step a for calcination in a tube furnace, raise the temperature to 550°C at a rate of 5°C / min, keep it for 1h, then raise the temperature to 900°C, and keep it for 1h. A black solid was obtained, and then the black solid was washed with water and 10 wt % hydrochloric acid until neutral, and dried at 120° C. for 4 hours to obtain biomass-based nitrogen-doped porous carbon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com