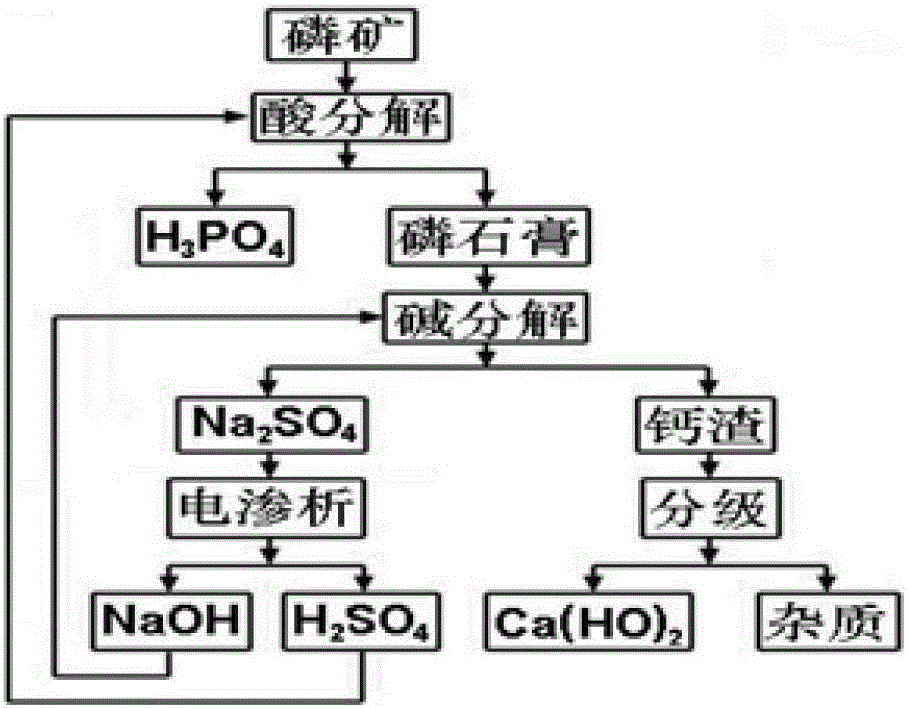

Technology for cyclic decomposing, transforming and using ardealite with two-step method

A technology of phosphogypsum and two-step method, which is applied in the field of cyclic decomposition and transformation of phosphogypsum by two-step method, which can solve the problems of low market demand for converted products and high cost of comprehensive utilization of phosphogypsum, so as to reduce raw material cost, easy process, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

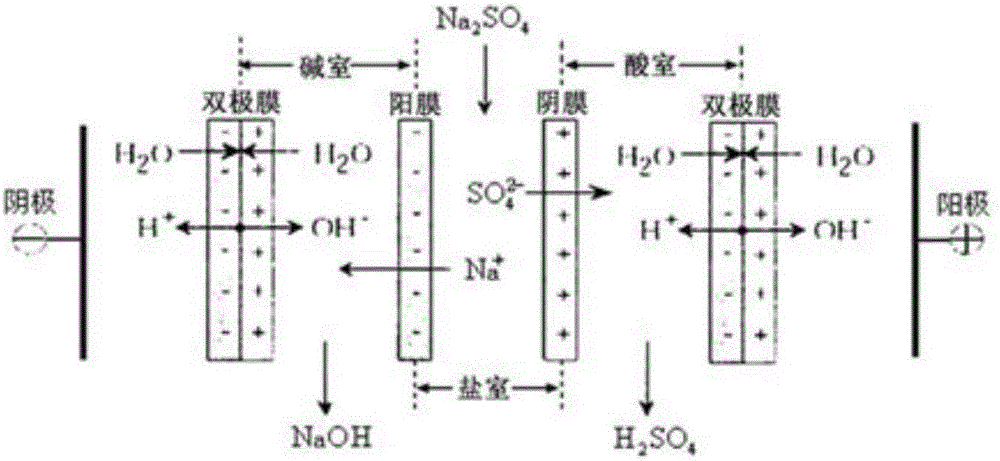

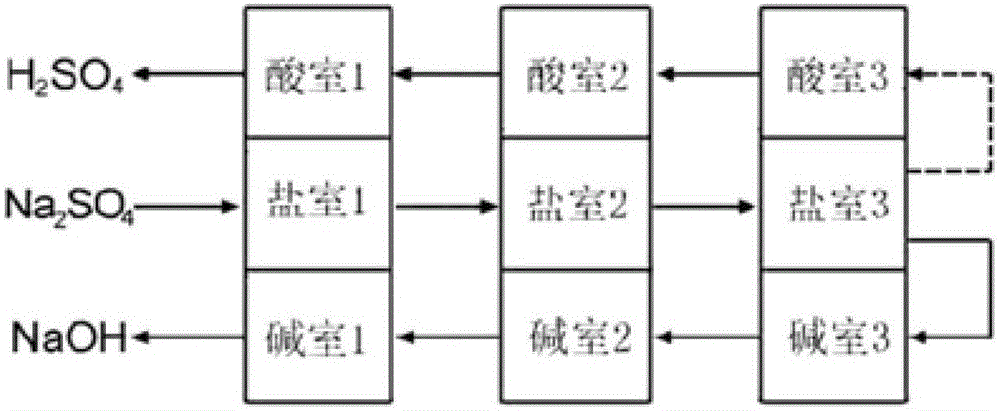

Method used

Image

Examples

Embodiment 1

[0036] A two-step recycling process for decomposing and transforming phosphogypsum, comprising the following steps:

[0037] (1) The concentration is 9.16wt% NaOH solution, according to sodium hydroxide and CaSO 4 The theoretical molar amount required for the reaction is 2:1, and it is added to the reactor containing the phosphogypsum raw material; at the same time, ethanol is added in a proportion of 0.2wt% of the phosphogypsum mass, and at room temperature with a stirring speed of 6.3m / s, Stirring reaction 10min; Then slowly add excess NaOH solution (the molar weight of sodium hydroxide is CaSO 40.15 times the molar weight), continue to stir the reaction for 5min. Then stop stirring, the slurry is settled and filtered, and the filter residue is countercurrently washed twice to obtain a mass concentration of 15.03% Na 2 SO 4 Solution and Calcium Slag, CaSO 4 The decomposition conversion rate is 96.25%. Calcium slag is separated into particle sizes below 20 μm by hydrauli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com