Environment-friendly crude oil decalcifying agent

A crude oil decalcifying agent, an environmentally friendly technology, applied in the treatment of hydrocarbon oil, petroleum industry, non-metallic refining, etc., can solve the problems of easy blockage of equipment pipelines by sediment, large amount of decalcifying agent, poor adaptability of crude oil, etc., to achieve Improve the chemical reaction rate, shorten the reaction time, easy to separate the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

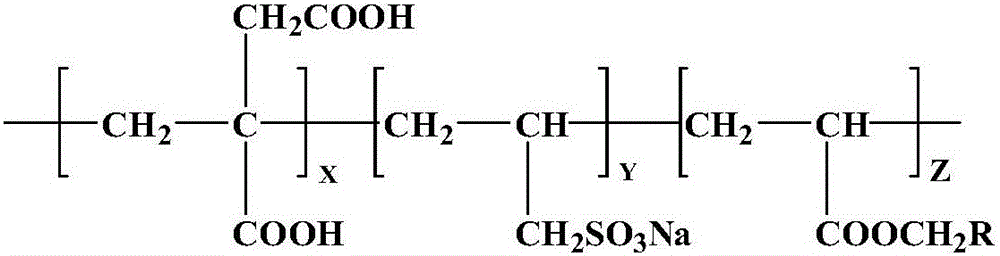

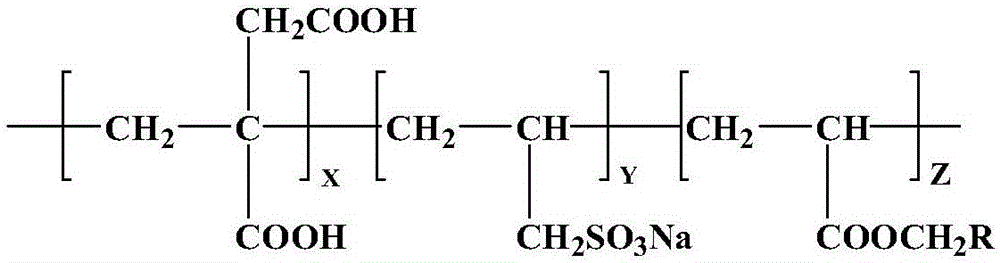

[0026] N 2Atmosphere, add 180g sodium allyl sulfonate and 90g itaconic acid into the reaction kettle at 25°C, mix well and heat up to 90°C, then add 140g hydroxyethyl acrylate and 100g water, mix well and add dropwise 65g of sodium persulfate aqueous solution with a concentration of 10wt.% and 40g of sodium sulfite aqueous solution with a mass percentage concentration of 10wt.%. , remove the microwave field, adjust the temperature to 75°C, continue the reaction for 4h, after cooling to room temperature, prepare 610g of polycarboxylate sodium sulfonate chelating agent, cool to 25°C, add 350g of sulfamic acid, 350g of polyacrylic acid, Mix 450g of diethylenetriamine to obtain an organic compound, then add 6175g of distilled water and mix to obtain an environment-friendly crude oil decalcifier.

[0027] After the determination of demetallization rate, the decalcification rate of the environment-friendly crude oil decalcification agent is 83.8%, and the iron removal rate is 58.4%...

Embodiment 2

[0029] Polycarboxylate sodium sulfonate chelating agent adopts the chelating agent prepared by example 1, polycarboxylate sulfonate sodium ester chelating agent 610g, sulfamic acid 350g, maleic acid / acrylic acid copolymer 260g, nitrinitrogen Mix 520g of triacetic acid to obtain an organic compound, then add 5220g of distilled water and mix to obtain an environment-friendly crude oil decalcifier.

[0030] After the determination of the demetallization rate, the decalcification rate of the environment-friendly crude oil decalcification agent is 83.2%, and the iron removal rate is 49.3%.

Embodiment 3

[0032] Polycarboxylate sodium sulfonate chelating agent adopts the chelating agent prepared by example 1, polycarboxylate sulfonate sodium ester chelating agent 610g, citric acid 150g, sulfamic acid 150g, hydrolyzed polymaleic anhydride 300g, Mix 300g of hexamethylenetetramine to obtain an organic compound, then add 3020g of distilled water and mix to obtain an environmentally friendly crude oil decalcifier.

[0033] Through the determination of demetallization rate, the decalcification rate of the environment-friendly crude oil decalcification agent is 86.9%, and the iron removal rate is 65.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com