Fluorescent tracing non-phosphate polyether multifunctional water treatment agent and preparation method of water treatment agent

A water treatment agent and fluorescent tracer technology, applied in the field of pharmaceuticals, can solve the problems of unsatisfactory dispersing Fe ability, easy generation of calcium gel, and inability to detect the concentration of water treatment agents on-line, so as to achieve on-line detection and automatic drug delivery , The preparation process is green and environmentally friendly, and the effect of good biodegradation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

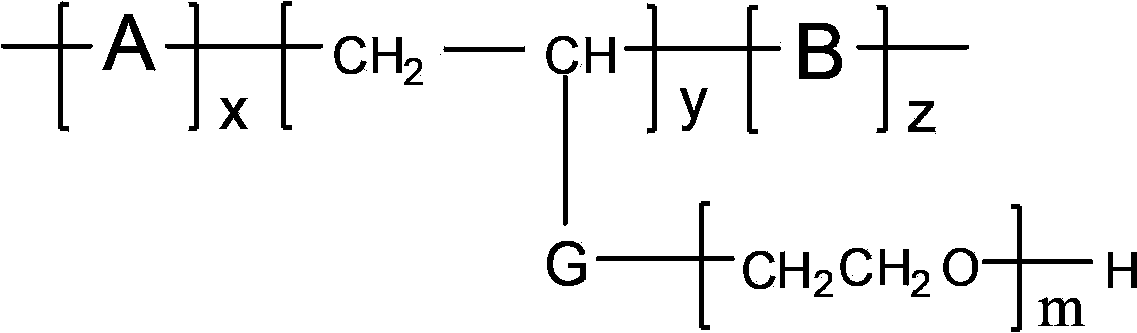

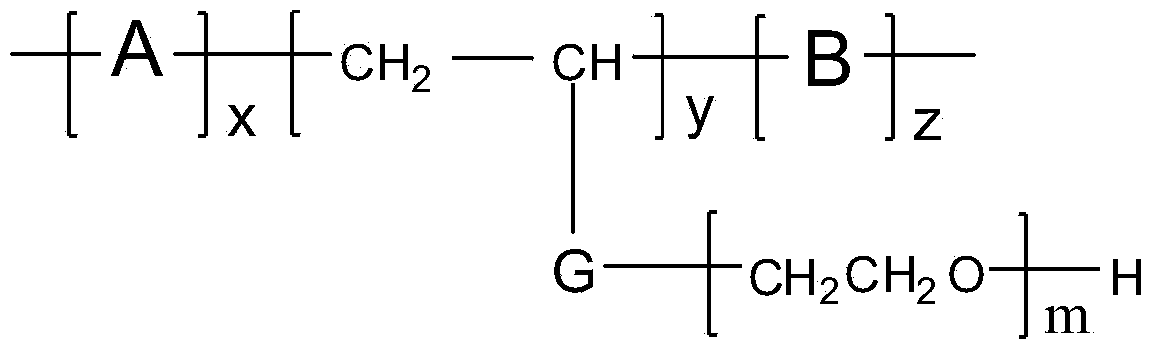

[0018] Example 1: at N 2 Add 100g of allyl polyethylene glycol monoether to the protected reactor, adjust the temperature to 70°C, add 25g of acrylic acid, 0.5g of 8-allyloxy-1,3,6-sodium pyrenetrisulfonate, 350g Water, after mixing, add 5g of sodium persulfate (dissolved in 100g of water) dropwise. After 2h of dropwise addition, raise the temperature to 85°C and continue the reaction for 2h. After cooling down to room temperature, a fluorescent tracer phosphorus-free polyether multifunctional water treatment agent (APEGYG).

[0019] When the obtained APEGYG dosage is 8mg / L, the Ca 3 (PO 4 ) 2 Scale inhibition rate can reach 98.9%, for CaCO 3 Scale inhibition rate is 90.6%, for CaSO 4 The scale inhibition rate is 95.1%, the light transmittance of Fe(III) solution, which characterizes the performance of dispersing iron, is 16.3%, and the corrosion inhibition rate of carbon steel can reach 92.3%.

example 2

[0020] Example 2: at N 2 Add 100g of vinyl polyethylene glycol monoether to the protected reactor, adjust the temperature to 75°C, add 100g of itaconic acid, 5g of 8-allyloxy-1,3,6-sodium pyrenetrisulfonate, 260g Water, after mixing, add dropwise the mixture of potassium persulfate (3g), sodium persulfate (3g) and potassium metabisulfinate (3g) (dissolved in 120g water), after 3.5h dropwise addition, heat up to 90°C to continue the reaction After 3.5 hours, after cooling down to room temperature, a fluorescent tracer phosphorus-free polyether multifunctional water treatment agent (APEGYG) was prepared.

[0021] When the obtained APEGYG dosage is 8mg / L, to Ca 3 (PO 4 ) 2 Scale inhibition rate can reach 98.7%, for CaCO 3 Scale inhibition rate is 89.9%, for CaSO 4 The scale inhibition rate is 91.3%. , The light transmittance of Fe(III) solution, which characterizes the performance of dispersing iron, is 15.9%, and the corrosion inhibition rate of carbon steel can reach 92.6...

example 3

[0022] Example 3: at N 2 Add 110g of allyl polyethylene glycol monoether to the protected reactor, adjust the temperature to 60°C, add 100g of hydroxyethyl methacrylate, 15g of 8-allyloxy-1,3,6-pyrene trisulfone Sodium persulfate, 380g water, after mixing, add 50g sodium persulfate (dissolved in 80g water) dropwise, after 4 hours of dropwise addition, raise the temperature to 95°C and continue the reaction for 2 hours, after cooling down to room temperature, a fluorescent tracer phosphorus-free polyether is prepared Multifunctional water treatment agent (APEGYG).

[0023] When the obtained APEGYG dosage is 8mg / L, to Ca 3 (PO 4 )2 Scale inhibition rate up to 99.5%, for CaCO 3 Scale inhibition rate is 88.9%, for CaSO 4 The scale inhibition rate is 92.7%, the light transmittance of the Fe(III) solution which characterizes the performance of dispersing iron is 17.2%, and the corrosion inhibition rate of carbon steel can reach 95.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com