Red mud comprehensive utilization treatment method

A treatment method and technology of red mud, applied in coating, alkali metal hydroxide, aluminum hydroxide preparation and other directions, can solve the problems of large equipment loss, complex composition, no enrichment effect, etc., and achieve the effect of reducing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

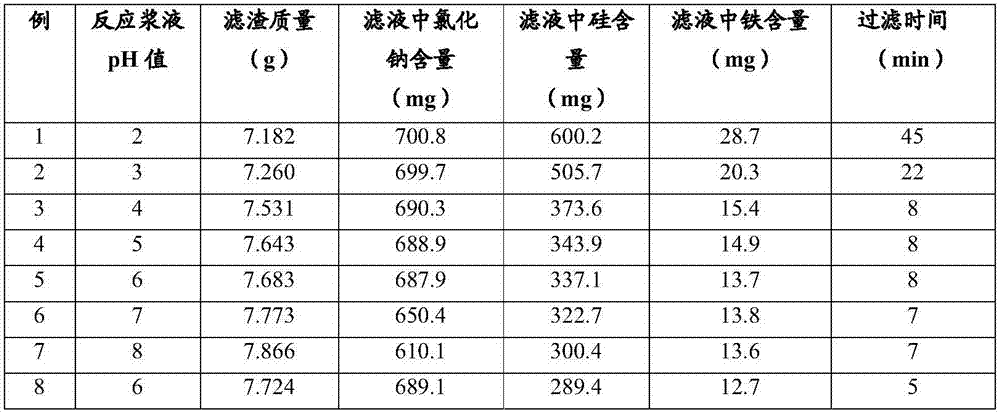

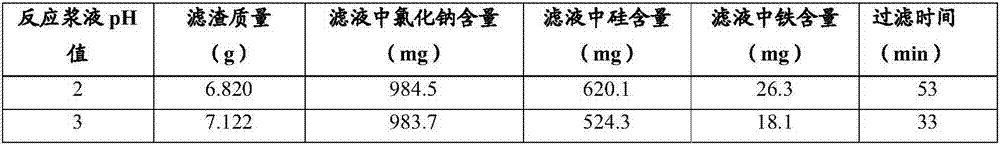

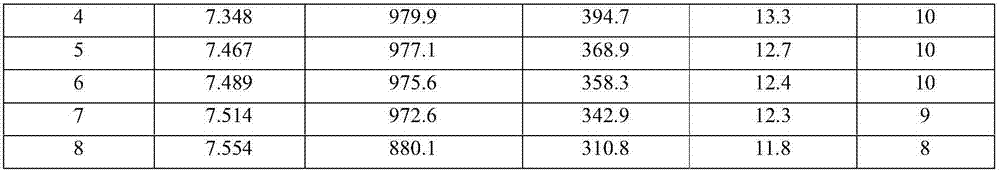

Examples

Embodiment 1

[0029] A red mud comprehensive utilization treatment method, comprising the following steps:

[0030] (1) Red mud acidification treatment

[0031] Add water and hydrochloric acid solution to the red mud, stir, and prepare a slurry with a pH value of 4, and then react at 0°C for 50 hours. After the reaction is completed, the solid and liquid are separated, and the solid phase obtained is weakly acidic red mud residue for alkali removal. The obtained liquid phase is processed in the next step;

[0032] (2) Processing of the liquid phase and solid phase that step (1) obtains

[0033] Treatment of the liquid phase obtained in step (1): Add sodium hydroxide solution to the liquid phase obtained in step (1), control the pH value to 5 after mixing, then stir and react at 100°C for 0.5 hours, and then separate the solid and liquid to obtain the solid The phase is an aluminum hydroxide product, and the obtained liquid phase mainly contains sodium chloride, which can be used as a moth...

Embodiment 2

[0036] A red mud comprehensive utilization treatment method, comprising the following steps:

[0037] (1) Red mud acidification treatment

[0038] Add water and hydrochloric acid solution to the red mud, stir, and prepare a slurry with a pH value of 5, and then react at 35°C for 2 hours. After the reaction is completed, the solid and liquid are separated, and the obtained solid phase is weakly acidic red mud residue for alkali removal. The obtained liquid phase is processed in the next step;

[0039] (2) Processing of the liquid phase and solid phase that step (1) obtains

[0040] The treatment of the liquid phase obtained in step (1): add sodium hydroxide solution to the liquid phase obtained in step (1), control the pH value to 8 after mixing, then stir and react at 40°C for 5 hours, and then separate the solid and liquid to obtain the solid The phase is an aluminum hydroxide product, and the obtained liquid phase mainly contains sodium chloride, which can be used as a mothe...

Embodiment 3

[0043] A red mud comprehensive utilization treatment method, comprising the following steps:

[0044] (1) Red mud acidification treatment

[0045] Add water and hydrochloric acid solution to the red mud, stir, and prepare a slurry with a pH value of 6, and then react at 30°C for 0.5 hours. After the reaction, the solid-liquid separation is completed, and the obtained solid phase is weakly acidic red mud residue for alkali removal. The obtained liquid phase is processed in the next step;

[0046] (2) Processing of the liquid phase and solid phase that step (1) obtains

[0047] Treatment of the liquid phase obtained in step (1): adding sodium hydroxide solution and calcium hydroxide solid in sequence to the liquid phase obtained in step (1), controlling the pH value to 7 after mixing, then stirring and reacting at 0°C for 50 hours, and then Solid-liquid separation, the obtained solid phase is aluminum hydroxide product, and the obtained liquid phase mainly contains sodium chlo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com