Method for magnesium oxide method power plant desulfurization wastewater zero discharging treatment

A treatment method and technology for desulfurization wastewater, applied in gaseous discharge wastewater treatment, water/sewage treatment, chemical instrument and method, etc. The effect of processing cost, realizing resource utilization, and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

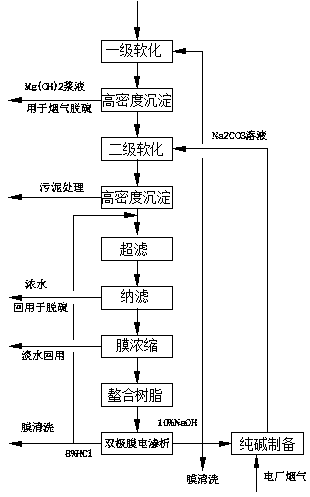

Image

Examples

Embodiment 1

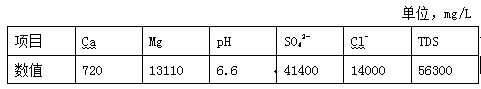

[0030] The water quality of desulfurization wastewater from a magnesia power plant is shown in Table 1, unit, mg / L

[0031]

[0032] The waste water first enters the primary softening unit, adding sodium hydroxide solution and a large amount of Mg in the water 2+ Formation of Mg(OH) 2 Precipitation, while removing trace amounts of other heavy metal ions in water such as Cu, As, Pb, etc., sodium hydroxide comes from the bipolar membrane electrodialysis unit in the system, in which NaOH and Mg 2+ The molar ratio is 2:1, and the residence time is 20min.

[0033] The first-stage softened mud-water mixture enters the high-density precipitation unit for precipitation, and the obtained Mg(OH) 2 The precipitation slurry is reused for flue gas desulfurization to absorb sulfur dioxide in the flue gas of the power plant. The precipitation time is 3 hours, and the high-density precipitation water Mg 2+ Reduced to below 20mg / L.

[0034] The high-density precipitation supernatant ent...

Embodiment 2

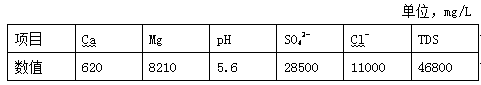

[0042] The water quality of desulfurization wastewater from a magnesia power plant is shown in Table 1, unit, mg / L

[0043]

[0044] The waste water first enters the primary softening unit, adding sodium hydroxide solution and a large amount of Mg in the water 2+ Formation of Mg(OH) 2 Precipitation, while removing trace amounts of other heavy metal ions in water such as Cu, As, Pb, etc., sodium hydroxide comes from the bipolar membrane electrodialysis unit in the system, in which NaOH and Mg 2+ The molar ratio is 2.5:1, and the residence time is 30min.

[0045] The first-stage softened mud-water mixture enters the high-density precipitation unit for precipitation, and the obtained Mg(OH) 2 The precipitation slurry is reused for flue gas desulfurization to absorb sulfur dioxide in the flue gas of the power plant. The precipitation time is 4 hours, and the high-density precipitation water Mg 2+ Reduced to below 20mg / L.

[0046] The high-density precipitation supernatant e...

Embodiment 3

[0054] The water quality of desulfurization wastewater from a magnesia power plant is shown in Table 1, unit, mg / L

[0055]

[0056] The waste water first enters the primary softening unit, adding sodium hydroxide solution and a large amount of Mg in the water 2+ Formation of Mg(OH) 2 Precipitation, while removing trace amounts of other heavy metal ions in water such as Cu, As, Pb, etc., sodium hydroxide comes from the bipolar membrane electrodialysis unit in the system, in which NaOH and Mg 2+ The molar ratio is 3:1, and the residence time is 30min.

[0057] The first-stage softened mud-water mixture enters the high-density precipitation unit for precipitation, and the obtained Mg(OH) 2 The precipitation slurry is reused for flue gas desulfurization to absorb sulfur dioxide in the flue gas of the power plant. The precipitation time is 4 hours, and the high-density precipitation water Mg 2+ Reduced to below 20mg / L.

[0058] The high-density precipitation supernatant ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com