Three-channel alkali liquor distributor

A distributor and three-channel technology, applied in the direction of liquid distribution, distribution devices, special distribution devices, etc., can solve problems such as equipment cannot be guaranteed, and achieve the effects of ensuring long-term operation, improving corrosion resistance, and avoiding energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

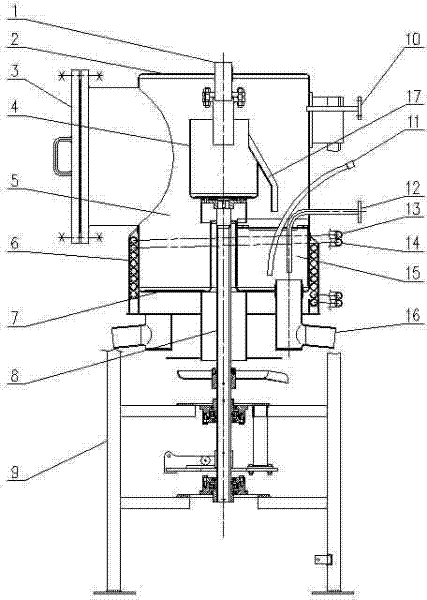

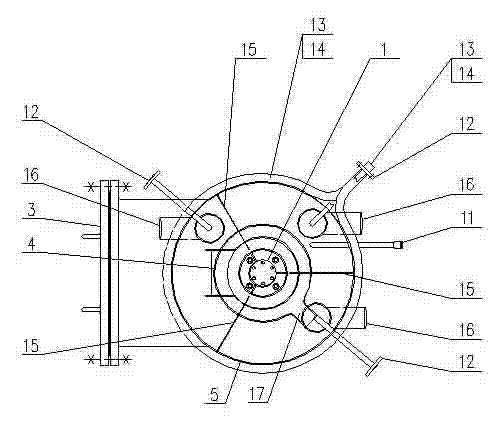

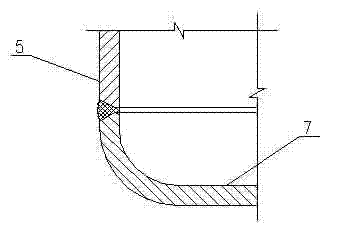

[0022] Such as Figure 1 ~ Figure 3 As shown, a three-channel lye distributor: a cylinder body (5), a top plate (2) and a bottom plate (7) are welded to form a closed tank. Such as image 3 As shown, in order to reduce the stress at the welding seam, the top plate (2) and the bottom plate (7) are connected to the cylinder (5) with a flanging butt joint structure; the top plate (2) is provided with a lye inlet pipe (1) to ensure the The molten lye level inside is stable, and the lye inlet pipe adopts an enlarged diameter structure to reduce the lye flow rate, namely: the lye inlet pipe (1) adopts a stepped tubular structure with a lower end diameter larger than an upper end diameter. Three lye outlet pipes (16) are arranged on the bottom plate (7), and the lye outlet pipe (16) has a certain inclination so that the materials can be completely drained.

[0023] The molten salt coil (13) and steam coil (14) are installed outside the tank for heating. The molten salt coil (13) and st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com