Method for preparing polypropylene / nano composite dielectric with high direct current breakdown field strength

A nano-composite, breakdown field strength technology, applied in fixed capacitor dielectrics, flat products, fixed capacitor components, etc., can solve problems affecting the safe and stable operation of UHV transmission systems, DC filter single capacitor failure, unbalanced Alarms and other problems, to achieve the effect of improving the safety margin of the medium, increasing the DC breakdown strength, and reducing the operating failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A preparation method of polypropylene / nano composite dielectric with high DC breakdown field strength, the specific steps are as follows:

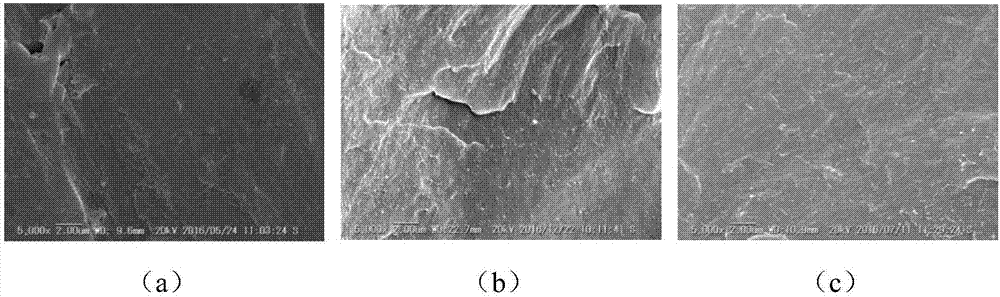

[0039] (1) Preparation of pure polypropylene dielectric

[0040] a) Insulate the HC-312 polypropylene base particles produced by Borealis at 50° C. for 2 hours to remove moisture. Weigh 30 g of dried polypropylene granules.

[0041] b) Heat the dried polypropylene base material in a HAAKE PolyLab QC torque rheometer at 170-180°C for 5 minutes, and adjust the temperature to 170°C after the base material particles are completely melted. The rotational speed of the torque rheometer is divided into three gears, each being 50 rpm, 100 rpm, and 150 rpm, and each is continuously stirred for 30 minutes.

[0042] c) After the stirring is finished, adjust the torque rheometer to 150°C. Turn on the stirring chamber of the torque rheometer to obtain pure polypropylene medium, and place it at room temperature to cool.

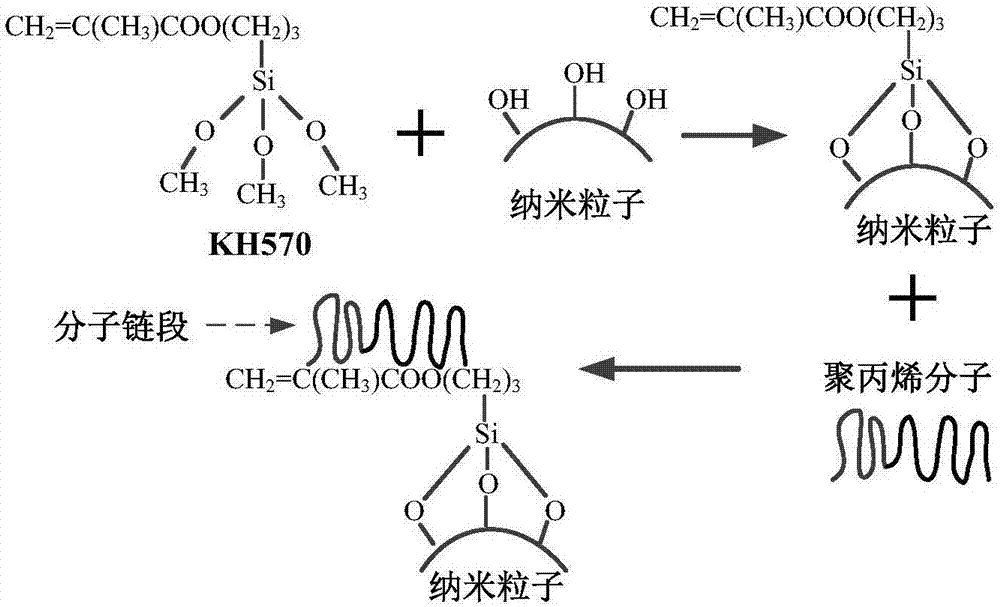

[0043] (2) Surface mo...

Embodiment 2

[0070] A preparation method of polypropylene / nano composite dielectric with high DC breakdown field strength, comprising the following steps:

[0071] 1) Select a silane coupling agent to modify the surface of the nanoparticles; the nanoparticles are MgO;

[0072] 2) Add the polypropylene base material into the cavity of the torque rheometer, heat up the particles and add the nanoparticles modified by the silane coupling agent after the particles are melted, and keep stirring at 170°C to prepare polypropylene / nano-MgO with uniformly dispersed nanoparticles. Composite dielectric; nanoparticles account for 0.5% of the mass of polypropylene particles;

[0073] 3) Use a flat vulcanizer to heat press polypropylene / nanocomposite dielectrics with a sandwich structure. The vulcanization process of the flat vulcanizer is: preheating for 300s, exhausting for 15 times, precompressing for 10s, and vulcanization time for 250s; MgO composite dielectric film. (other concrete steps are with...

Embodiment 3

[0075] A preparation method of polypropylene / nano composite dielectric with high DC breakdown field strength, comprising the following steps:

[0076] 1) Select a silane coupling agent to modify the surface of the nanoparticles; the nanoparticles are SiO 2 ;

[0077] 2) Add the polypropylene base material into the cavity of the torque rheometer, heat up the particles and add the nanoparticles modified by the silane coupling agent after the particles are melted, and keep stirring at 175°C to obtain polypropylene / nano-SiO with uniformly dispersed nanoparticles 2 Composite dielectric; nanoparticles account for 5% of the mass of polypropylene particles;

[0078] 3) Use a flat vulcanizer to heat press polypropylene / nanocomposite dielectrics with a sandwich structure. The vulcanization process of the flat vulcanizer is: preheating for 400s, exhausting 13 times, precompressing for 8s, and vulcanization time for 260s; SiO 2 Composite Dielectric Films. (other concrete steps are wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com