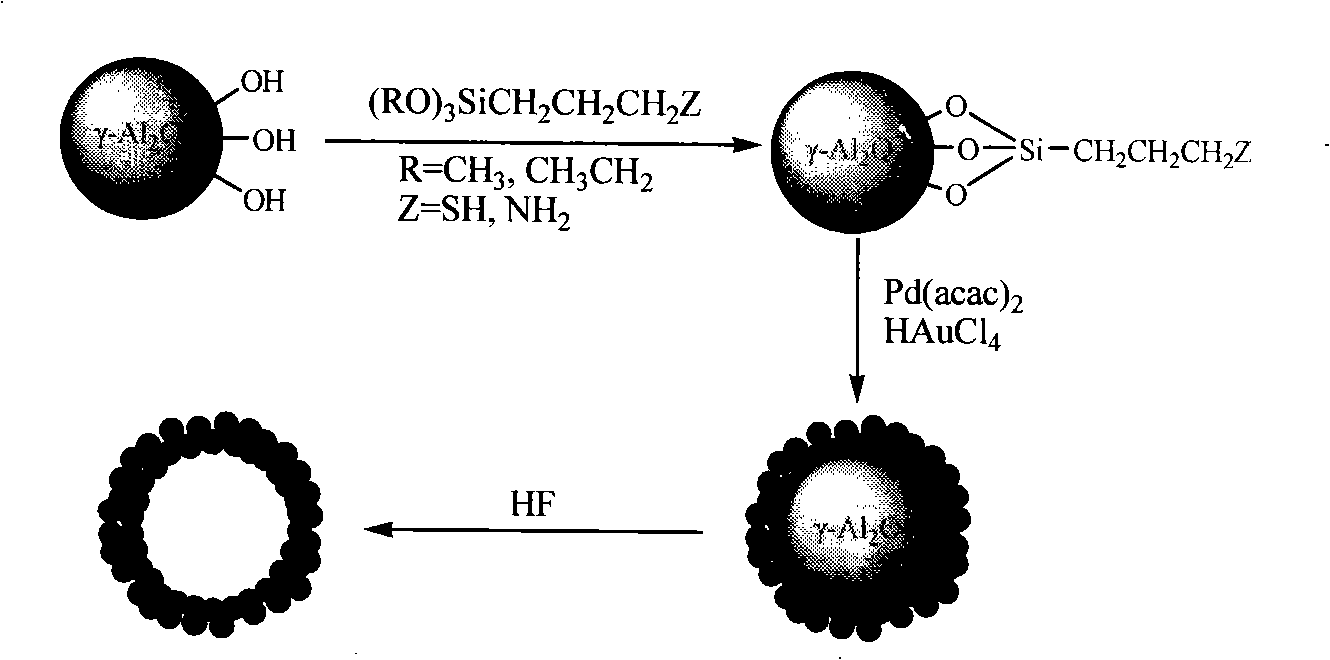

Method for preparing hollow metal nano-particle with gamma-aluminum oxide nano-particle as mould plate

A technology of metal nanoparticles and aluminum oxide nanometers, which is applied in the field of preparation of nanostructure materials, and achieves the effects of simple preparation process, easy operation and easy modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

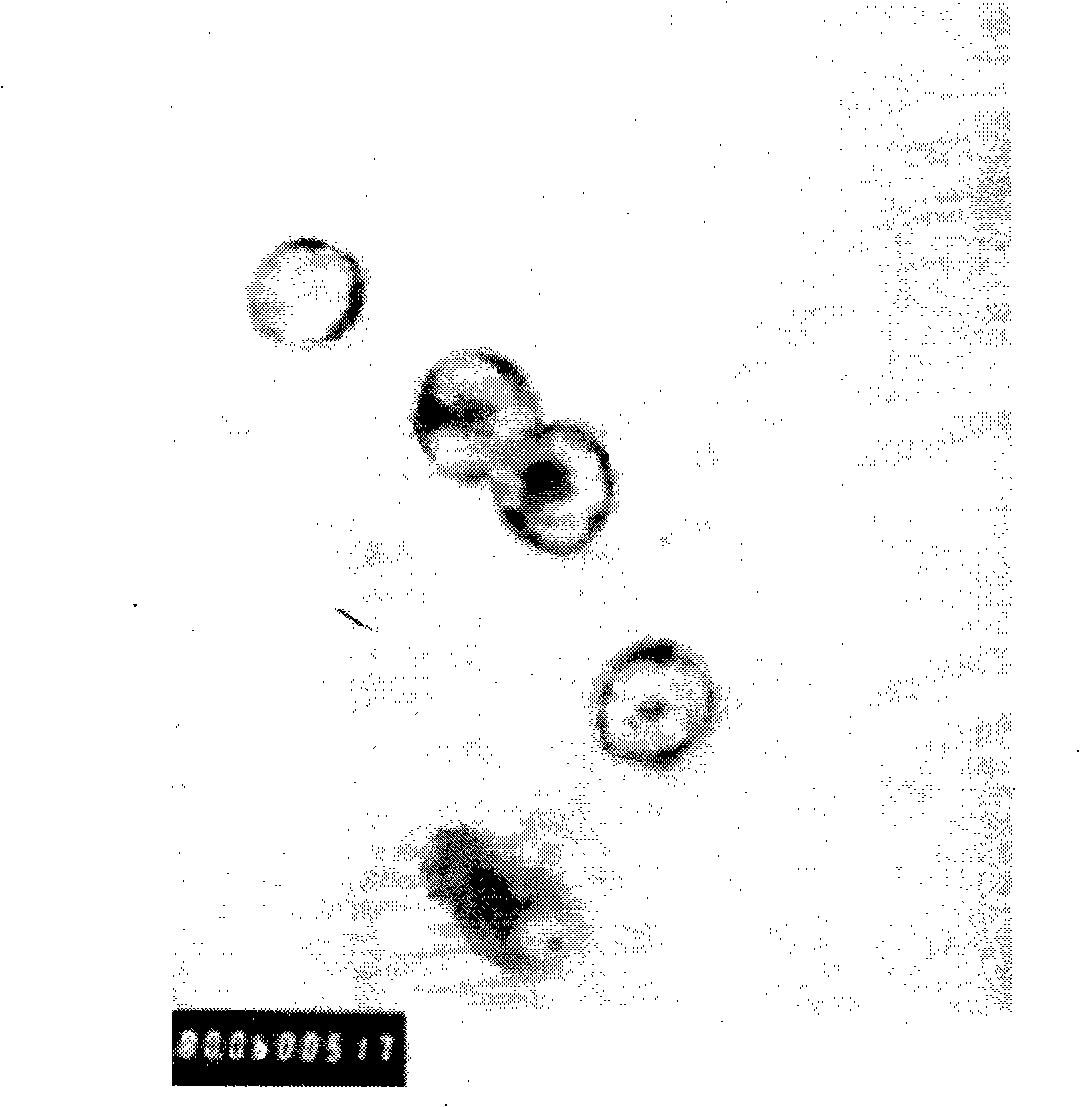

[0014] First add 20mL dry toluene to the reaction flask, then add 1.3mL γ-mercaptopropyltriethoxysilane and 0.30g γ-Al 2 O 3 Nano particles were dispersed by ultrasonic, refluxed for 24 hours and then centrifuged / re-dispersed repeatedly with absolute ethanol to clean the particles, and the resulting product was dried at 50°C. Then add 0.18g of the above-mentioned silanized γ-Al to 5mL of palladium acetylacetonate in absolute ethanol solution (0.0302mol / L) 2 O 3 Nano-particles, ultrasonically dispersed, let stand for 30min, evaporate the absolute ethanol to dryness at low temperature, and then add to dioctyl ether and raise the temperature to 260℃ to remove Pd 2+ Reduced to metal Pd. Finally, the above-mentioned product was added to 20mL 40wt% HF solution at room temperature, ultrasonically dispersed, and then placed for 24h. Then, the nanoparticles were washed by repeated centrifugation / re-dispersion with deionized water and absolute ethanol successively, and the resulting particl...

Embodiment 2

[0016] Following the same procedure as in Example 1, using a 0.0532 mol / L palladium acetylacetonate solution in absolute ethanol, hollow palladium nanoparticles with a shell thickness of about 18 nm can be prepared.

Embodiment 3

[0018] Following the same procedure as in Example 1, using 0.0079 mol / L palladium acetylacetonate in anhydrous ethanol solution, hollow palladium nanoparticles with a shell thickness of about 3 nm can be prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com