Environmentally-friendly mixed refrigerant used for replacing R134a and preparation method of refrigerant

A mixed refrigerant and environmental protection technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of high flammability and high GWP value, and achieve the effect of good environmental protection performance, excellent thermal parameters and thermal performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

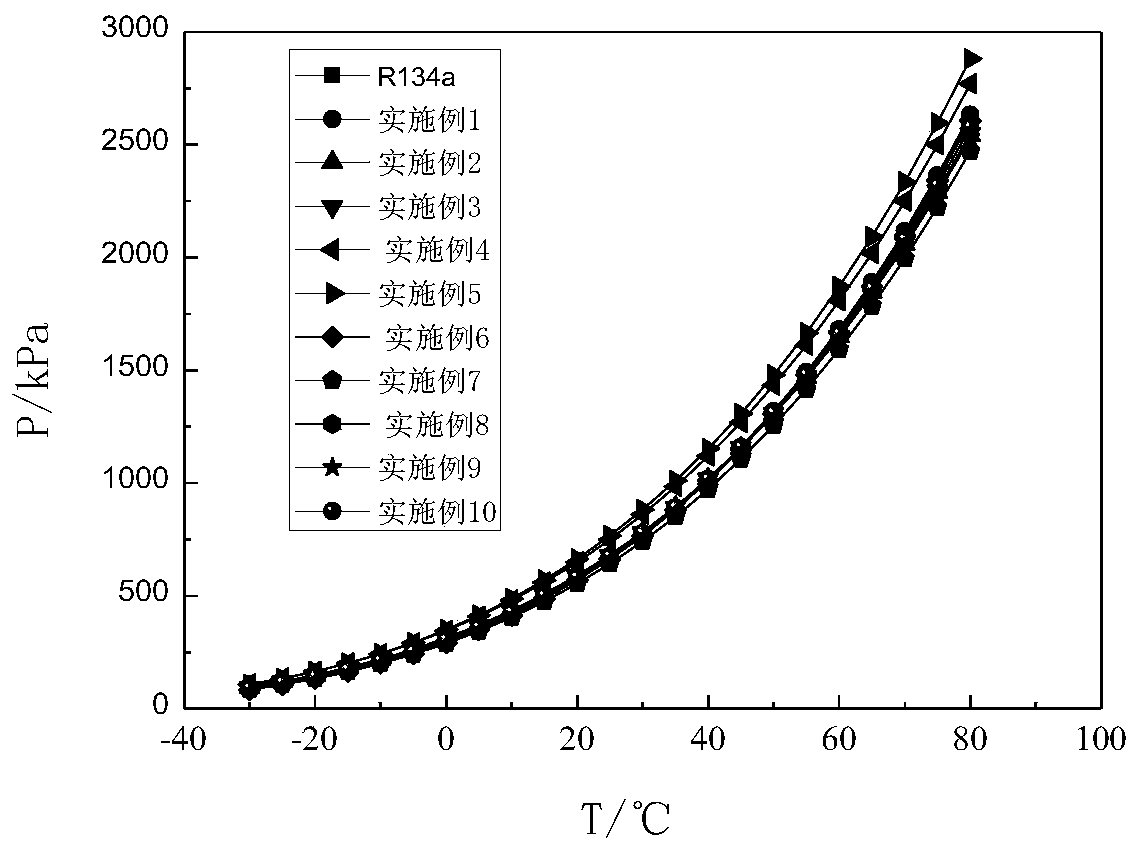

Image

Examples

Embodiment 1

[0022] The preparation of the mixed refrigerant is carried out in a 2L stainless steel stirring tank with cooling function. Set the temperature of the stirred tank at -10°C, and add 278.4g of 3,3,3-trifluoropropene, 54g of difluoromethane and 6222.2g of 1,1,1,2-tetrafluoroethane to the tank in sequence. After the sample is filled, Turn on the stirrer, cool down to -20°C, keep stirring for 2 hours, and control the pressure of the equilibrium tank within 0.2MPa, so that 3,3,3-trifluoropropene, difluoromethane and 1,1,1,2-tetrafluoroethane Mix in liquid state. After the treatment process, a mixed refrigerant is obtained, wherein the molar percentage of 3,3,3-trifluoropropene is 29%, the molar percentage of difluoromethane is 10%, 1,1,1,2-tetrafluoroethane The molar percentage of is 61%.

Embodiment 2~10

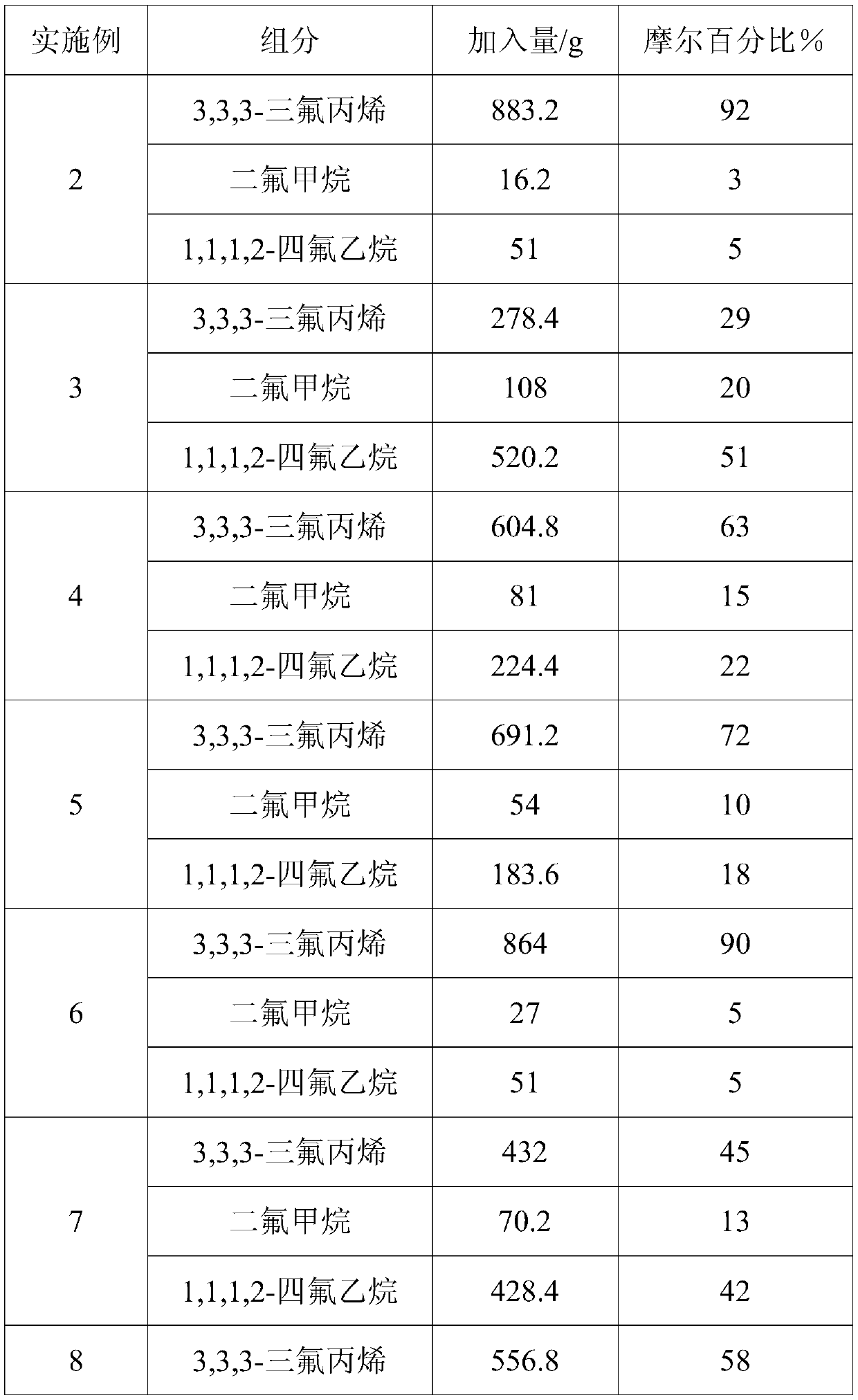

[0024] Examples 2-10 The preparation method of environmentally friendly mixed refrigerants is similar to that of Example 1, the difference is that 3,3,3-trifluoropropene, difluoromethane and 1,1,1,2-tetrafluoroethane are changed The mole percentage, the specific usage is as shown in Table 1.

[0025] Table 1

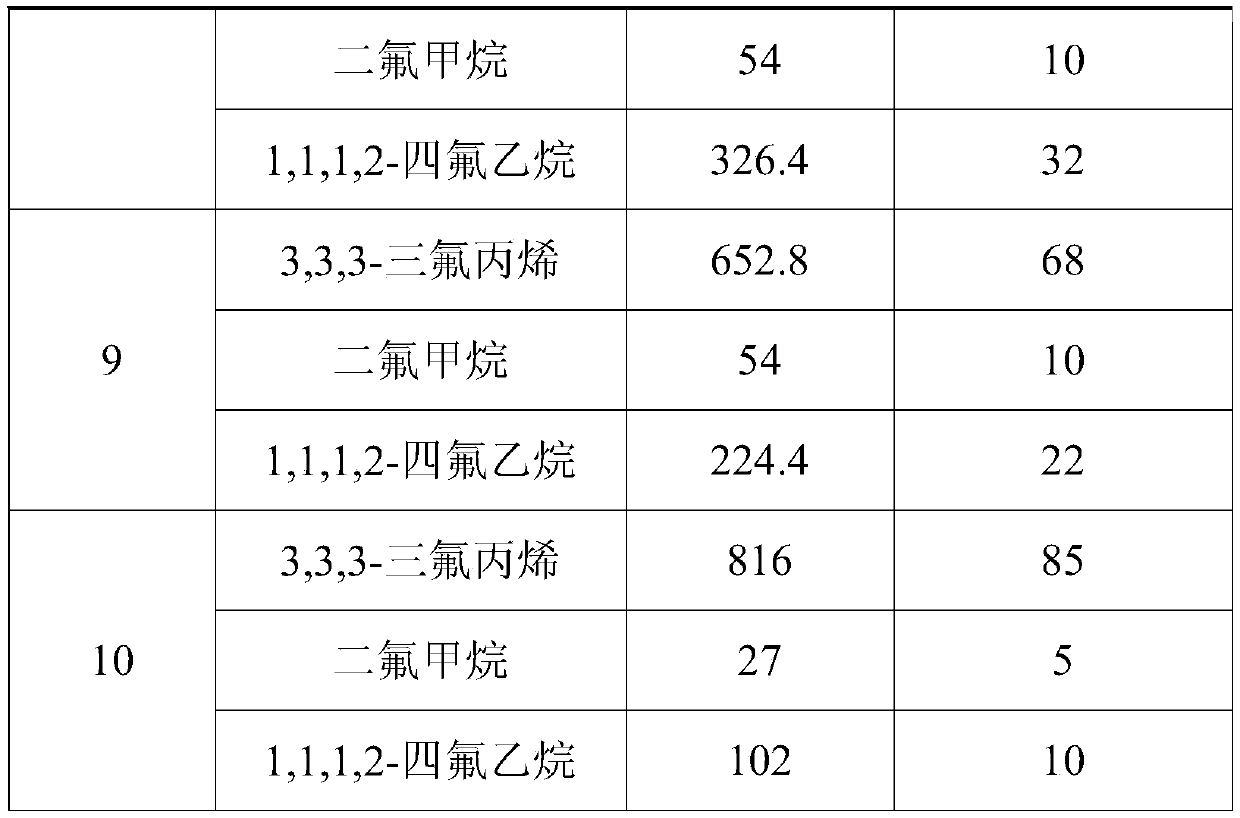

[0026]

[0027]

Embodiment 11

[0029] The preparation of the mixed refrigerant is carried out in a 2L stainless steel stirring tank with cooling function. First, 1.60 g of nanoparticle Fe 2 o 3 Add it to the balance tank, and set the temperature of the stirred tank to -10°C. Add 625.8g of 3,3,3-trifluoropropene, 54g of difluoromethane and 224.4g of 1,1,1,2-tetrafluoroethane to the kettle in sequence. After the sample is filled, turn on the stirrer and cool down to -20 ℃, keep stirring for 2 hours, and control the pressure of the equilibrium tank within 0.2 MPa, so that 3,3,3-trifluoropropene, difluoromethane and 1,1,1,2-tetrafluoroethane are mixed in a liquid state. After the treatment process, a mixed refrigerant is obtained, wherein the molar percentage of 3,3,3-trifluoropropene is 67.99%, the molar percentage of difluoromethane is 10%, 1,1,1,2-tetrafluoroethane The mole percentage is 22%, Fe 2 o 3 The molar percentage of nanoparticles is 0.01%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com