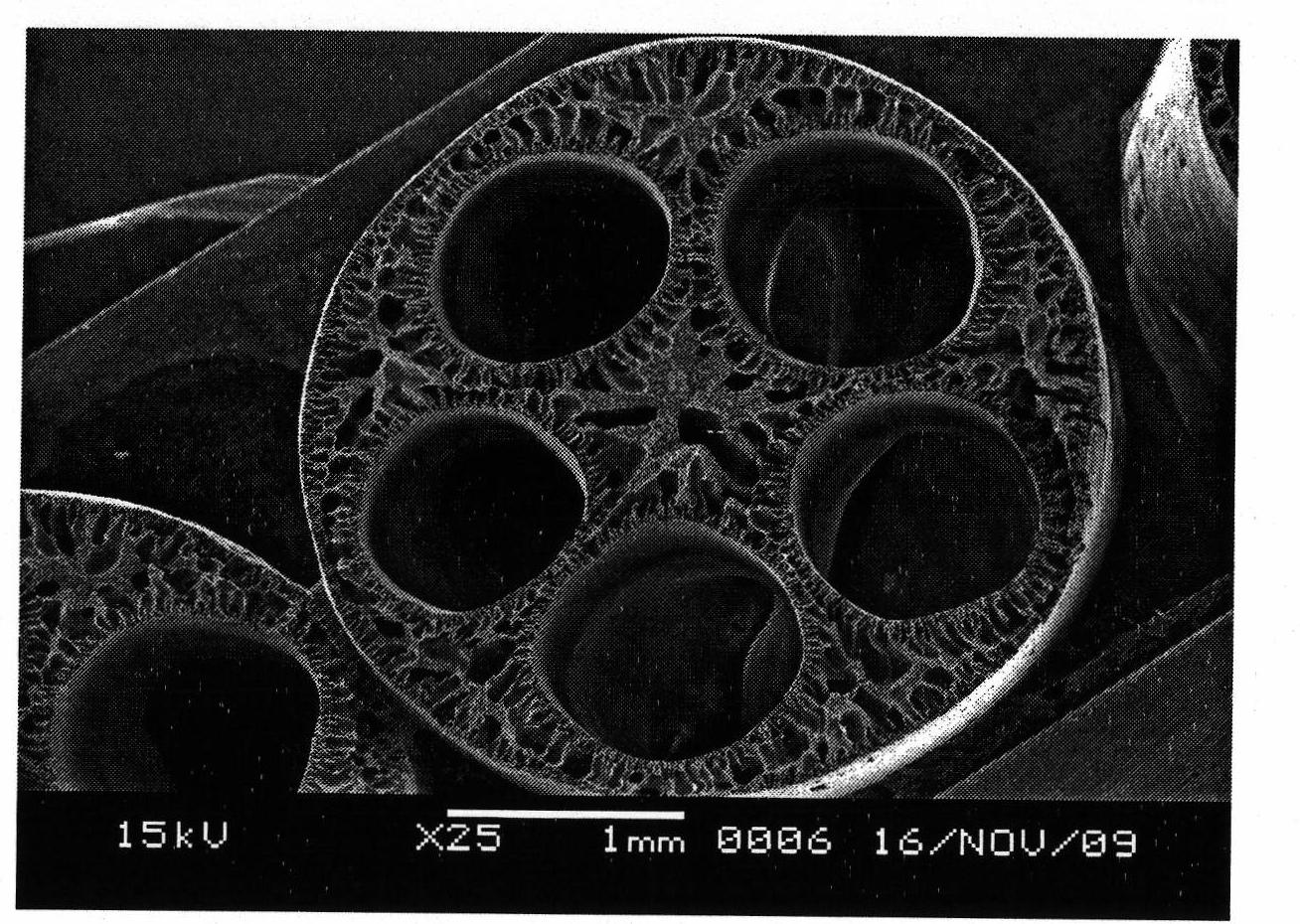

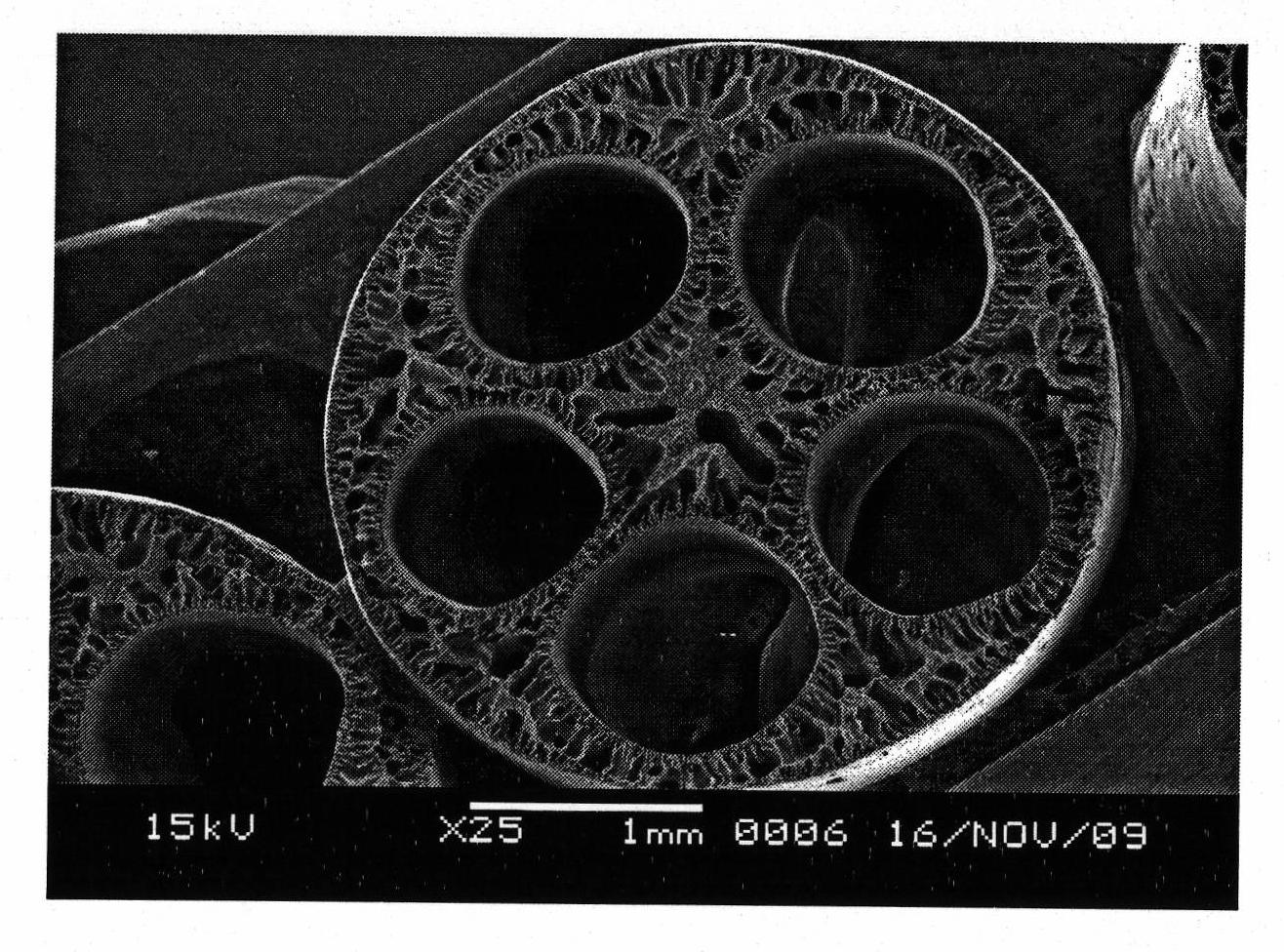

Three-component five-hole hollow fibrous membrane and preparation method thereof

A fiber membrane, three-component technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the adverse effects of subsequent unit operations of hollow fiber membranes, hollow fiber membranes have not yet been seen, and mechanical properties are not ideal, etc. problems, to achieve the effect of convenient source of raw materials, excellent mechanical properties and enhanced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

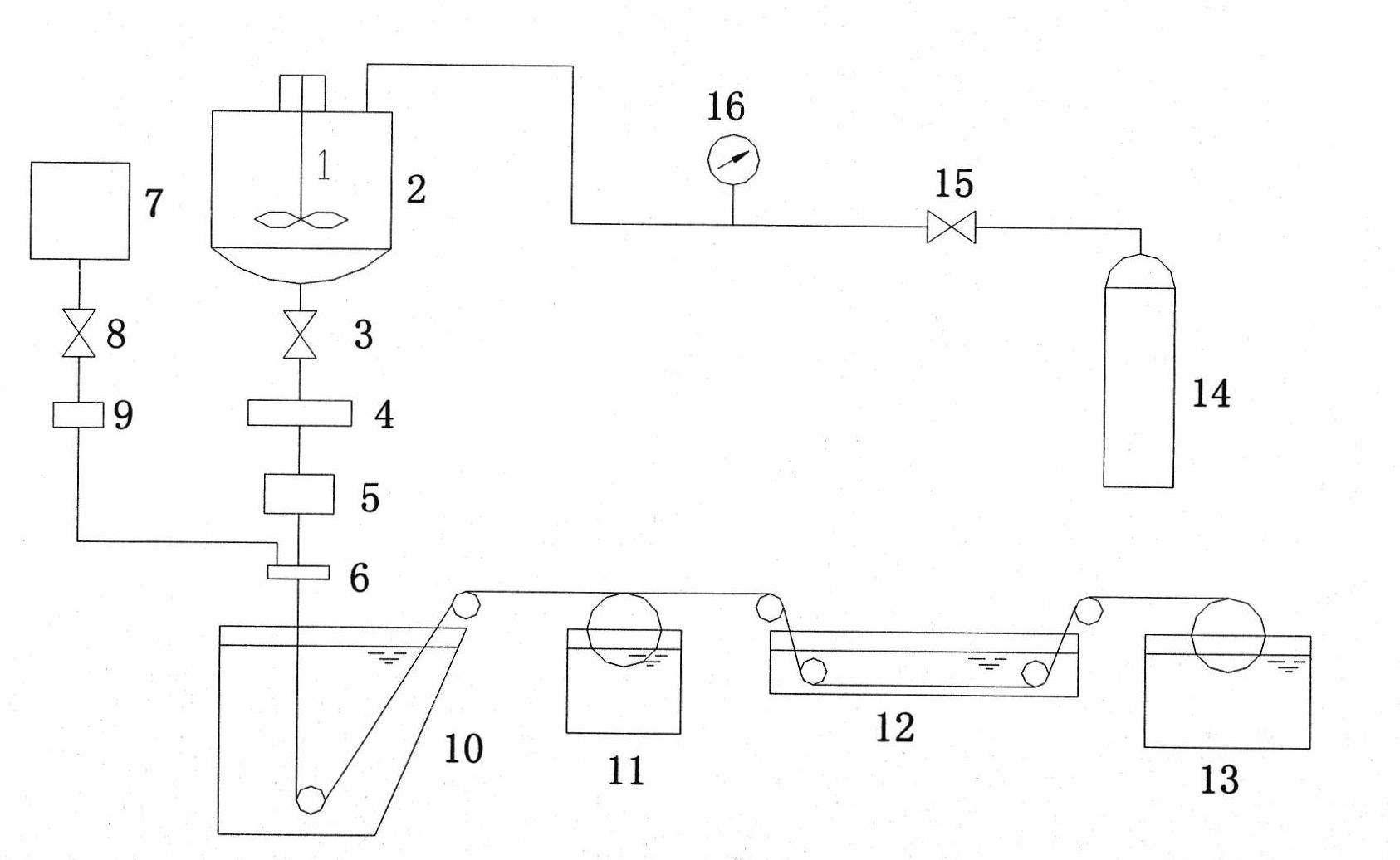

[0024] (1) Mix polyvinylidene fluoride, polymethyl methacrylate and polyvinyl chloride in a mass ratio of 60:30:10, add solvent N, N-dimethylacetamide and additive polyvinylpyrrolidone PVP and blend and stir for 24 Hours to dissolve, the dissolution temperature is 60 ~ 90 ℃;

[0025] (2) Aluminum oxide Al 2 o 3 The nanoparticles and the solvent N, N-dimethylacetamide were oscillated in an ultrasonic oscillator for 2 hours, mixed with the solution prepared in step (1), stirred evenly, and allowed to stand for 24 hours for defoaming to obtain a casting solution;

[0026] In the casting solution, the mass fraction of polymer is 10%, the mass fraction of polyvinylpyrrolidone is 10%; the mass fraction of aluminum oxide is 10%, and the rest is solvent N, N-dimethylacetamide;

[0027] (3) adopt dry-wet spinning process to carry out spinning, and technological condition is: dry spinning length is 3~15cm, and spinning pressure is 1atm, and core liquid is the N of 10~40wt%, N-dimethyl...

Embodiment 2

[0030] (1) Mix polyvinylidene fluoride, polymethyl methacrylate and polyvinyl chloride in a mass ratio of 80:10:10, add solvent N,N-dimethylacetamide and additive polyvinylpyrrolidone PVP and blend and stir for 24 Hours to dissolve, the dissolution temperature is 60 ~ 90 ℃;

[0031] (2) Aluminum oxide Al 2 o 3 The nanoparticles and the solvent N, N-dimethylacetamide were oscillated in an ultrasonic oscillator for 2 hours, mixed with the solution prepared in step (1), stirred evenly, and allowed to stand for 24 hours for defoaming to obtain a casting solution;

[0032] In the casting solution, the mass fraction of polymer is 25%, the mass fraction of polyvinylpyrrolidone is 1%; the mass percentage of aluminum oxide is 1%, and the rest is solvent N, N-dimethylacetamide;

[0033](3) adopt dry-wet spinning process to carry out spinning, and technological condition is: dry spinning length is 3~15cm, and spinning pressure is 1atm, and core liquid is the N of 5~40wt%, the N of N-di...

Embodiment 3

[0036] (1) Mix polyvinylidene fluoride, polymethyl methacrylate and polyvinyl chloride in a mass ratio of 60:10:30, add solvent N,N-dimethylacetamide and additive polyvinylpyrrolidone PVP and blend and stir for 24 Hours to dissolve, the dissolution temperature is 60 ~ 90 ℃;

[0037] (2) Aluminum oxide Al 2 o 3 The nanoparticles and the solvent N, N-dimethylacetamide were oscillated in an ultrasonic oscillator for 2 hours, mixed with the solution prepared in step (1), stirred evenly, and allowed to stand for 24 hours for defoaming to obtain a casting solution;

[0038] In the casting solution, the mass fraction of polymer is 15%, the mass fraction of polyvinylpyrrolidone is 5%; the mass percentage of aluminum oxide is 5%, and the rest is solvent N, N-dimethylacetamide;

[0039] (3) adopt dry-wet spinning process to carry out spinning, and technological condition is: dry spinning length is 3~15cm, and spinning pressure is 1atm, and core liquid is the N of 10~40wt%, N-dimethyla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water flux | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com