Water-based inorganic coating and preparation method thereof

A water-based inorganic coating and inorganic filler technology, applied in fire-resistant coatings, coatings, etc., can solve the problems of failing to exceed 1000 ℃, incompatibility with pickling performance, and only satisfying temperature resistance, so as to improve pickling resistance and low temperature. Excellent film-forming properties and the effect of improving high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The invention also provides a preparation method of the water-based inorganic paint, which is used to prepare the water-based inorganic paint. The preparation method comprises the following steps:

[0046] S1 sintering treatment to obtain inorganic filler, ready for use.

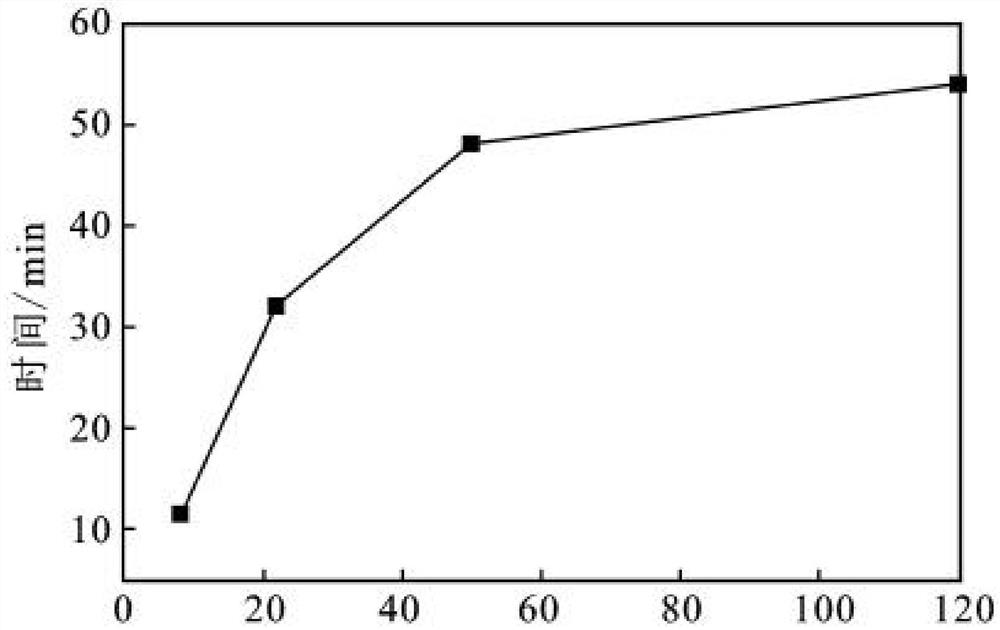

[0047] The sintering process is carried out in a sintering machine, and the parameters during the sintering process are set as follows: heating from room temperature to 180-250°C at a heating rate of 3-4°C / min, and keeping the temperature for 45min, and then continuing to heat at a heating rate of 5°C / min Heating rate to 400-600°C, holding for 2 hours, and finally heating at a heating rate of 4.5°C / min to 980-1200°C, holding for 3 hours, and then cooling with the furnace.

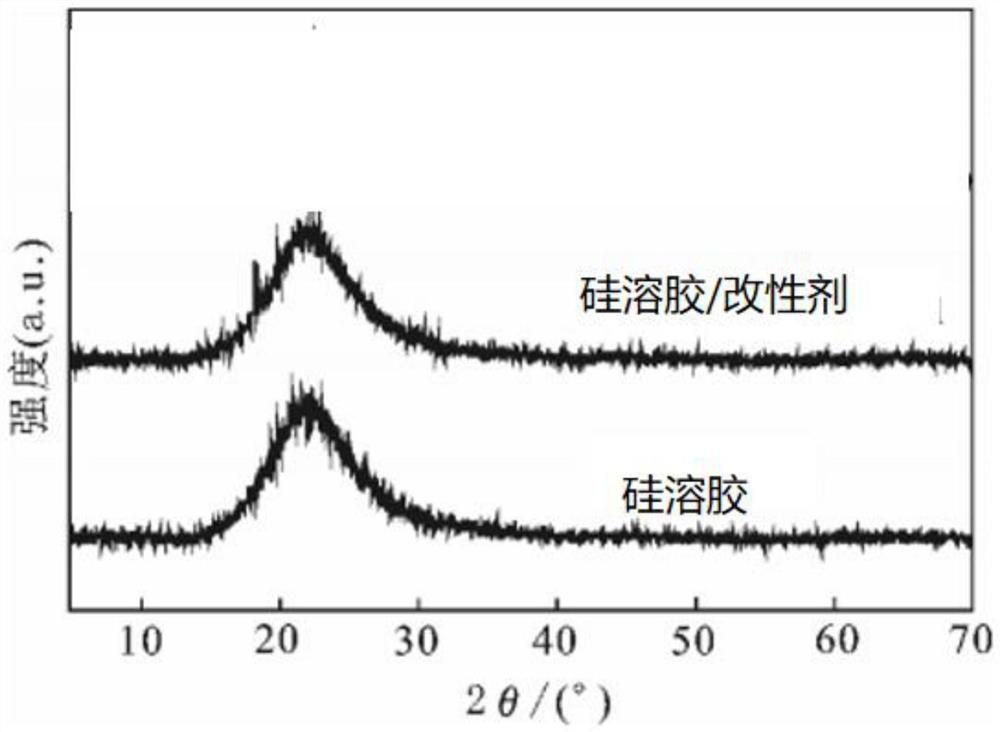

[0048]In the present invention, the high temperature resistance of the inorganic filler is improved by stabilizing the inorganic filler, that is, the corresponding sintering process is adopted, and its pickling resistance is impro...

Embodiment 1

[0055] This embodiment provides a water-based inorganic paint, the composition of which is as follows in parts by weight: 20 parts of silica sol, 30 parts of high-temperature-resistant inorganic pigments and fillers, 2.85 parts of additives, and 47.15 parts of deionized water. Deionized water is alkaline with a pH of 10. The particle size of high temperature resistant inorganic pigments and fillers is 800 mesh.

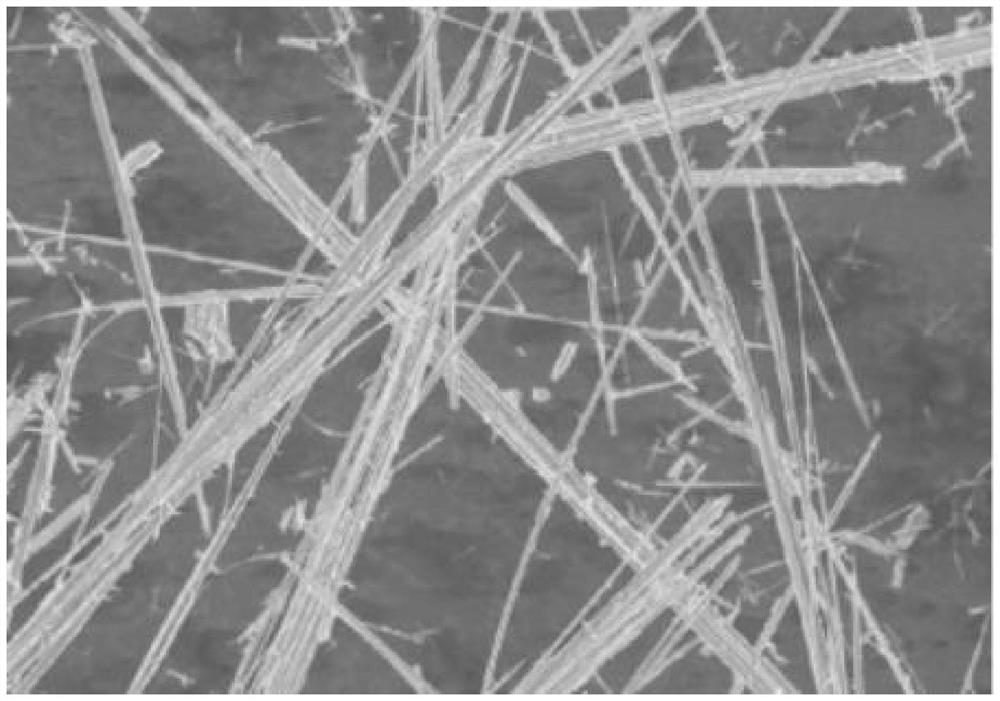

[0056] Wherein, the composition by weight of the high-temperature-resistant inorganic pigment and filler is as follows: 12 parts of lithopone, 10 parts of alumina powder, 5 parts of talcum powder, 3 parts of sepiolite, and 2 parts of microsilica powder. The alumina powder is γ-type alumina powder, which is obtained by heating aluminum hydroxide at 145° C. in a rotary evaporator. The additives are composed in parts by weight as follows: 0.2 part of methyl cellulose, 0.2 part of n-octanol, 0.15 part of sodium oleate, and 0.3 part of sodium bentonite.

[0057] In summa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com