NaOH-Al2O3/GO catalyst and anisole catalytic synthesis thereof

A catalyst and technology of anisole, applied in the field of NaOH-Al2O3/GO catalyst and its catalytic synthesis of anisole, can solve the problems of low yield of anisole, low preparation cost, low self-toxicity, etc., and improve catalytic activity , large specific surface area, the effect of preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

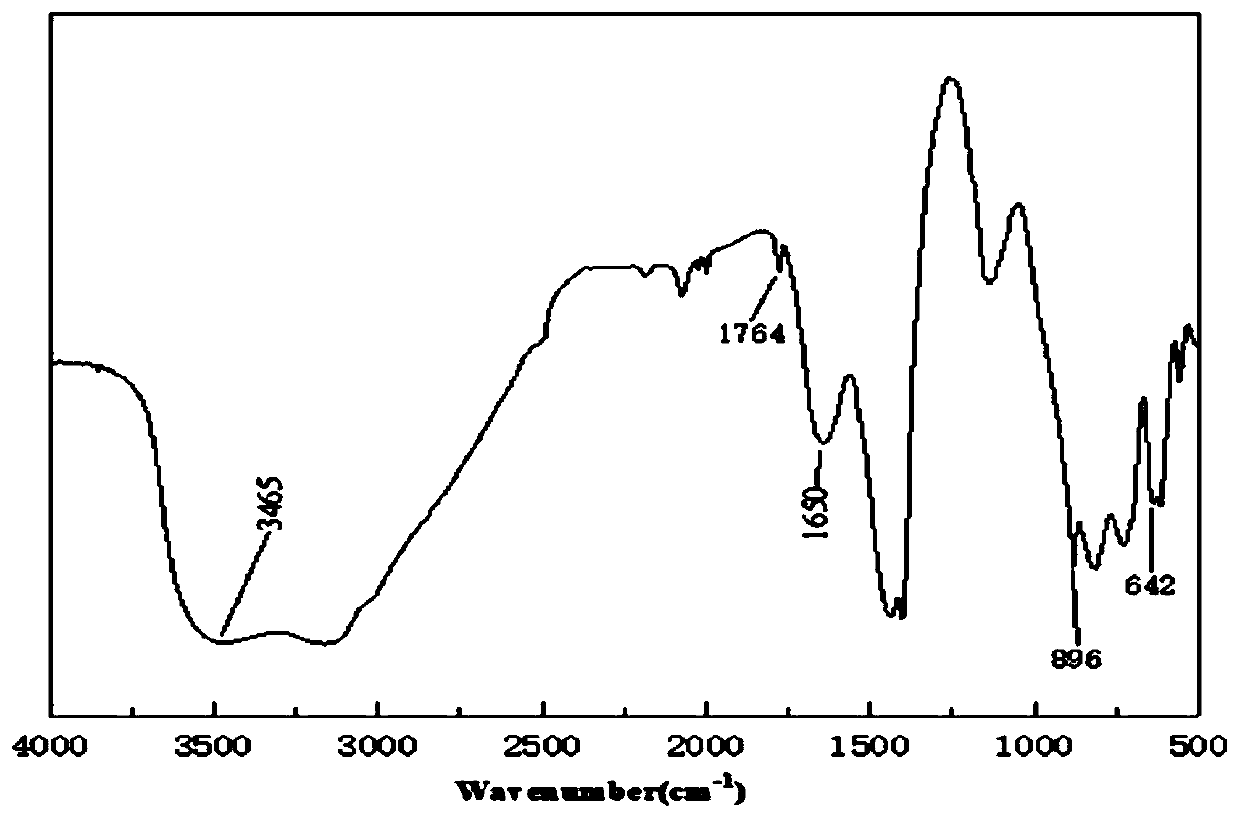

Embodiment 1

[0020] Weigh 0.12g of graphite oxide and add it to a 250mL beaker, add 120mL of deionized water to the beaker, stir evenly, put the beaker into an ultrasonic cleaner for ultrasonication for 2 hours, and mechanically peel off to form a brown transparent graphene oxide dispersion. Then, 1.5 g of aluminum nitrate and 1.3 g of urea were sequentially added to the graphene oxide dispersion, and the beaker was placed on a magnetic stirrer and stirred at room temperature for 2 hours to form a uniform dark brown mixture. Pour the dark brown mixture into a 200mL polytetrafluoroethylene-lined reaction kettle, then add 2mL N-methylpyrrolidone, stir evenly, put it into a blast drying oven, and react at 300°C for 12 hours under airtight conditions. After the reaction, cool to room temperature, wash the black solid by centrifugation, and dry at 70°C to obtain 0.3 g loaded Al 2 o 3 Nanoparticles of graphene oxide, denoted as Al 2 o 3 / GO. 0.3g Al 2 o 3 / GO was added to 10 mL of aqueous ...

Embodiment 2

[0022] Add dimethyl carbonate and phenol into the hydrothermal reaction kettle in different molar ratios, and add the NaOH-Al prepared in Example 1 with different mass contents of dimethyl carbonate and phenol total mass 2 o 3 / GO catalyst, and then reacted at different temperatures for different times under airtight conditions. The conversion rate of phenol and the proportion of anisole in the product were measured by gas chromatography-mass spectrometry (GC-MS). The specific reaction conditions and reaction results are shown in Table 1.

[0023] Table 1

[0024]

[0025] As can be seen from Table 1, the catalyst of the present invention is used to catalyze the reaction of dimethyl carbonate and phenol to synthesize anisole, and the conversion rate of phenol and the selectivity of anisole can reach more than 80%, which greatly improves the productive rate of anisole .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com