Enamel glaze powder and enamel liner of water heater

A kind of enamel glaze and water heater technology, which is applied in the direction of fluid heater, lighting and heating equipment, etc., can solve the problems of corrosion, water leakage, weight loss in boiling water, brittle enamel, etc., and achieve improved acid resistance and strength, lower weight loss in boiling water, and lower Effect of protection current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

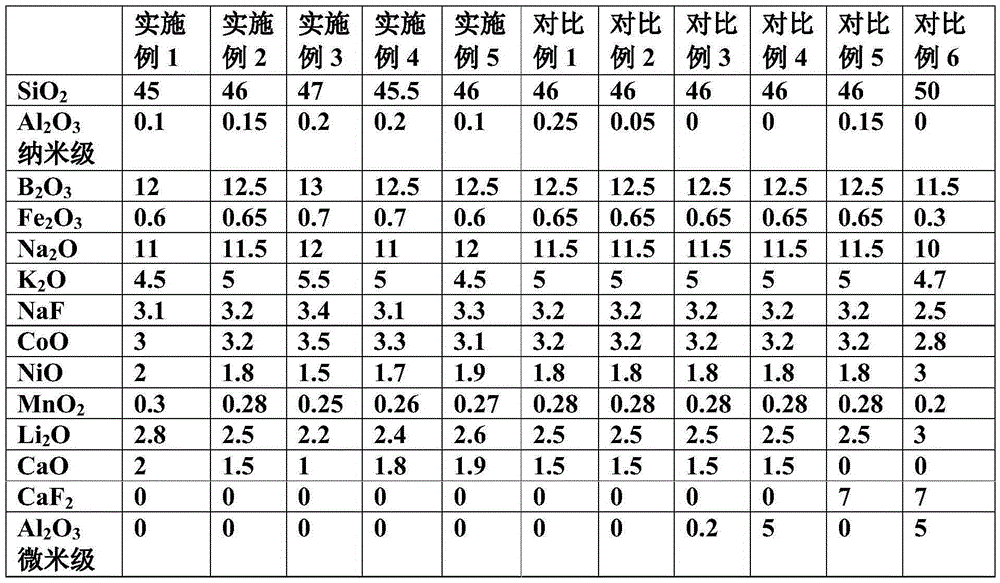

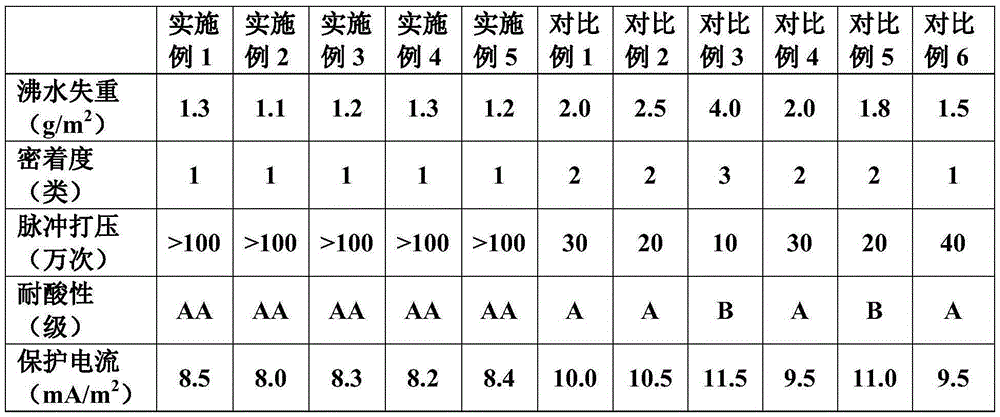

[0016] The enamel glaze powder for water heater enamel liner of the embodiment of the present invention can be made of following components (proportioning by weight): 45-47 parts of SiO 2 , 0.1-0.2 parts of Al 2 o 3 Nanoparticles, 12-13 parts of B 2 o 3 , 0.6-0.7 parts of Fe 2 o 3 , 11-12 parts of Na 2 O, 4.5-5.5 parts of K 2 O, 3.1-3.4 parts of NaF, 3-3.5 parts of CoO, 1.5-2 parts of NiO, 0.25-0.3 parts of MnO 2 , 2.2-2.8 parts of Li 2 O, 1-2 parts of CaO.

[0017] In the embodiment of the present invention, the Al in the enamel glaze powder 2 o 3 It is an essential ingredient to improve the chemical stability of the enamel glaze layer. Al added in the enamel glaze powder in the prior art 2 o 3 The size is usually on the order of tens to hundreds of microns, while Al 2 o 3 The content is usually 5-7%, or about 2-3%. Prior to the present invention, those skilled in the art had not realized that Al 2 o 3 The size of the enamel layer has an impact on the perfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com